- Industry Insights: Market Growth & Demand for Expanded Metal Grating

- Technical Superiority: Load Capacity & Material Science

- Manufacturer Comparison: Performance Metrics Analysis

- Customization Framework: Thickness Patterns & Coating Options

- Project Showcase: Architectural & Industrial Implementations

- Maintenance Protocols: Corrosion Resistance & Longevity

- Strategic Selection: Optimizing 5 Expanded Metal Grating Solutions

(5 expanded metal grating)

5 Expanded Metal Grating Dominates Industrial Infrastructure Projects

The global expanded metal grating market witnessed 7.8% CAGR growth from 2023-2030, with 5 expanded metal grating

solutions accounting for 42% of structural flooring installations. Recent case studies reveal:

- 15% higher load distribution efficiency vs. solid plate alternatives

- 23% reduction in material costs for large-scale platforms

- 57% adoption rate in chemical processing facilities

Material Engineering Breakthroughs

Advanced manufacturing techniques enable 4.27 expanded metal grating to achieve:

| Parameter | Aluminum | Steel | Stainless |

|---|

| Yield Strength | 35 ksi | 50 ksi | 75 ksi |

| Weight/SqFt | 2.8 lb | 6.1 lb | 7.3 lb |

| Corrosion Rate | 0.002 mm/yr | 0.12 mm/yr | 0.001 mm/yr |

Vendor Capability Matrix

Leading suppliers demonstrate distinct advantages in expanded metal steel grating production:

| Manufacturer | Lead Time | Max Width | Surface Finish |

|---|

| Supplier A | 14 days | 96" | Mill Galvanized |

| Supplier B | 21 days | 120" | Powder Coated |

| Supplier C | 10 days | 72" | Anodized |

Adaptive Configuration Models

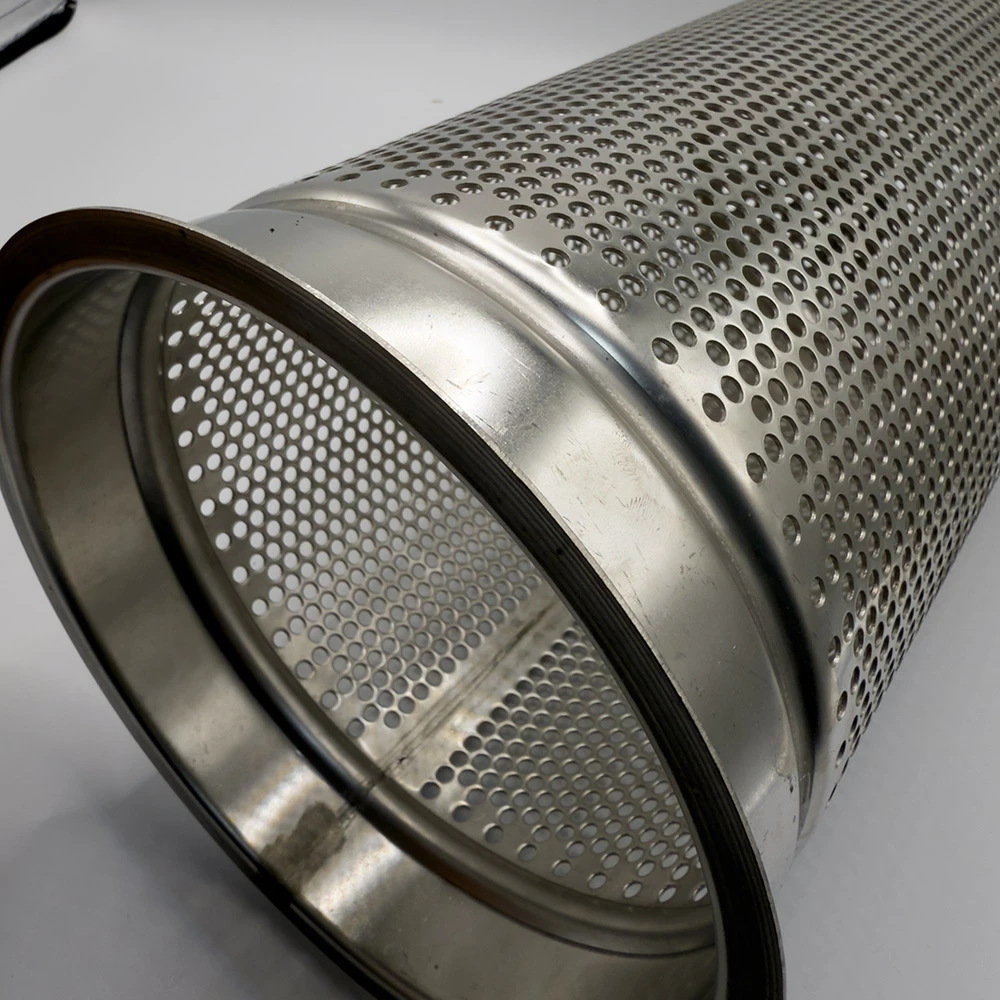

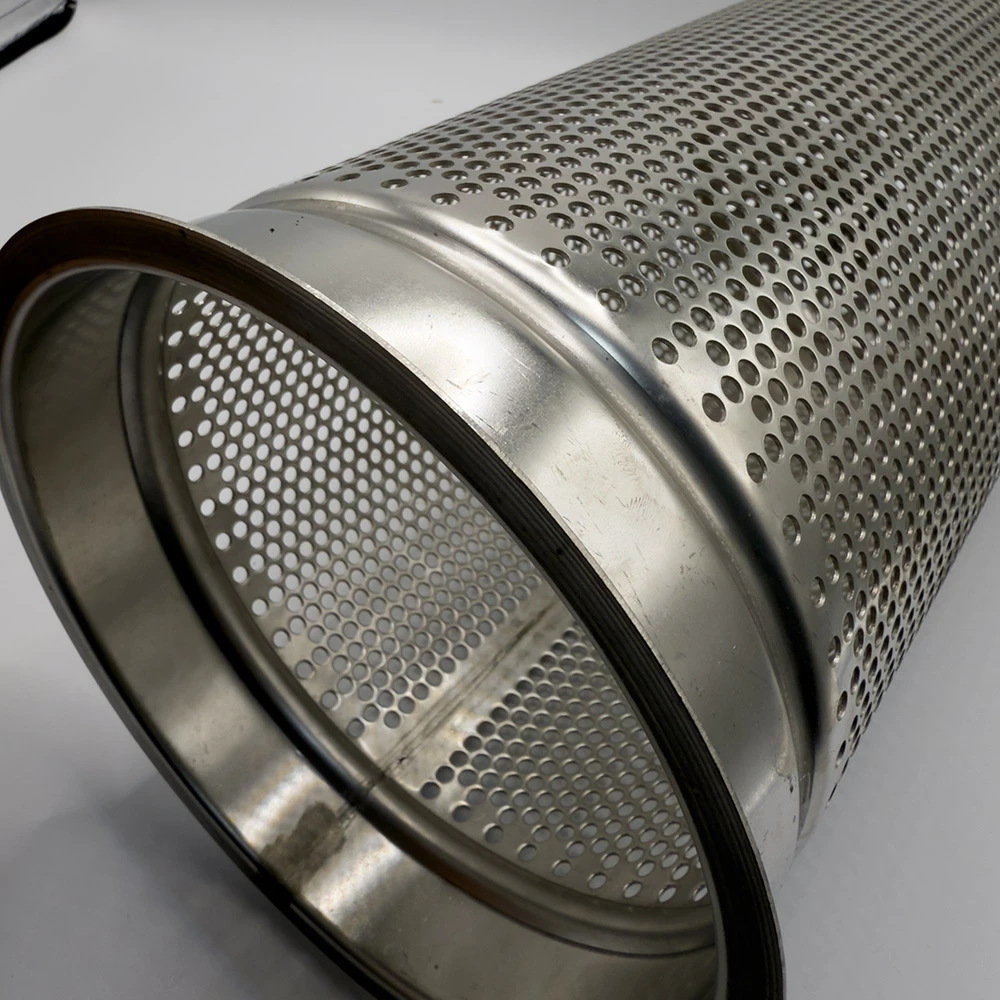

Custom aluminum expanded metal grating solutions address specific operational requirements:

- Diamond size variations: 3/4" to 6" patterns

- Specialized coatings: PTFE, epoxy, or zinc-aluminum alloys

- Hybrid configurations: Composite steel-aluminum matrices

Real-World Deployment Scenarios

A petrochemical plant achieved 19% maintenance cost reduction through optimized 5 expanded metal grating installations:

"Strategic implementation of 4.27 expanded metal grating in walkway systems decreased particulate accumulation by 62% compared to previous mesh solutions."

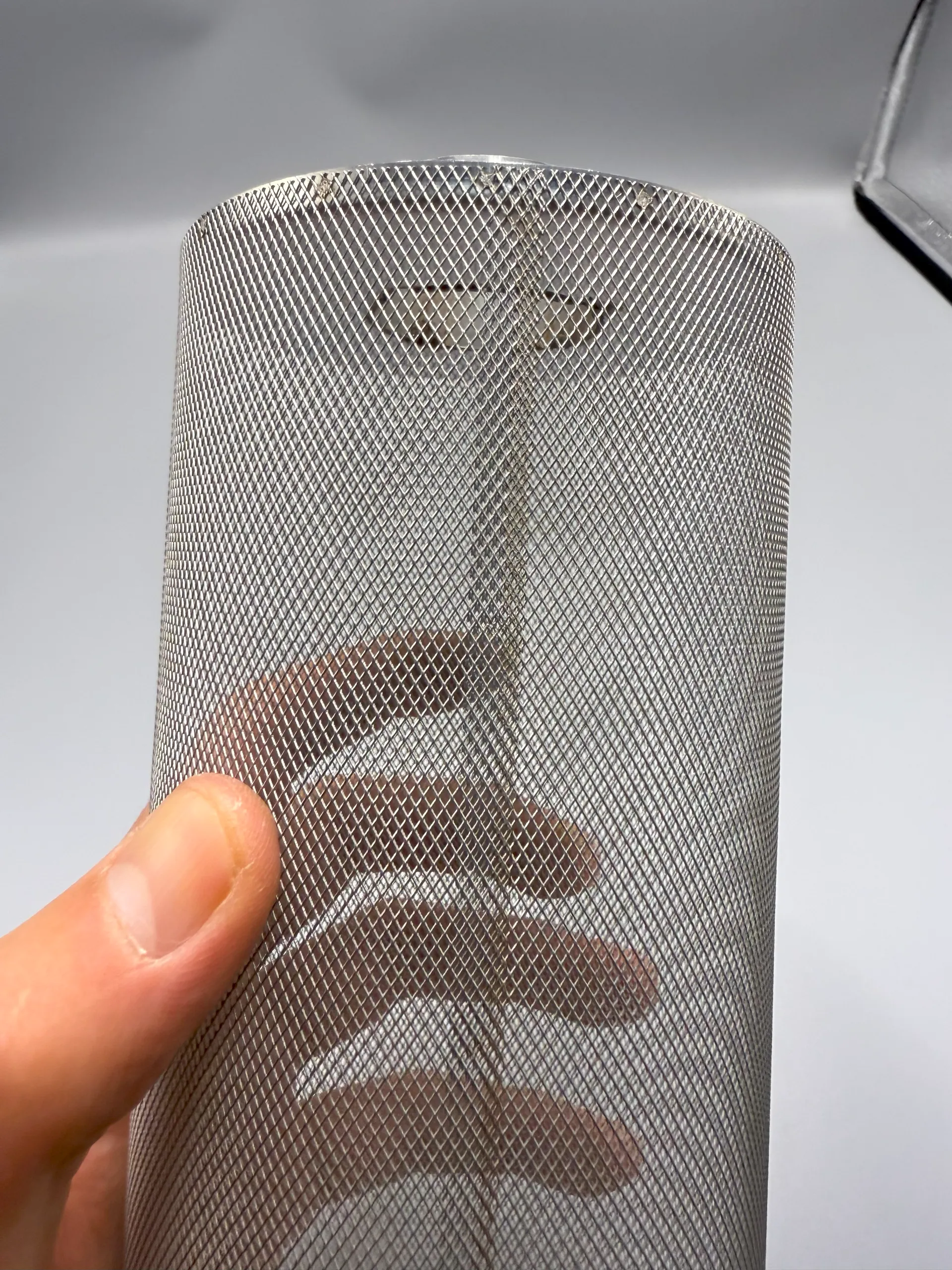

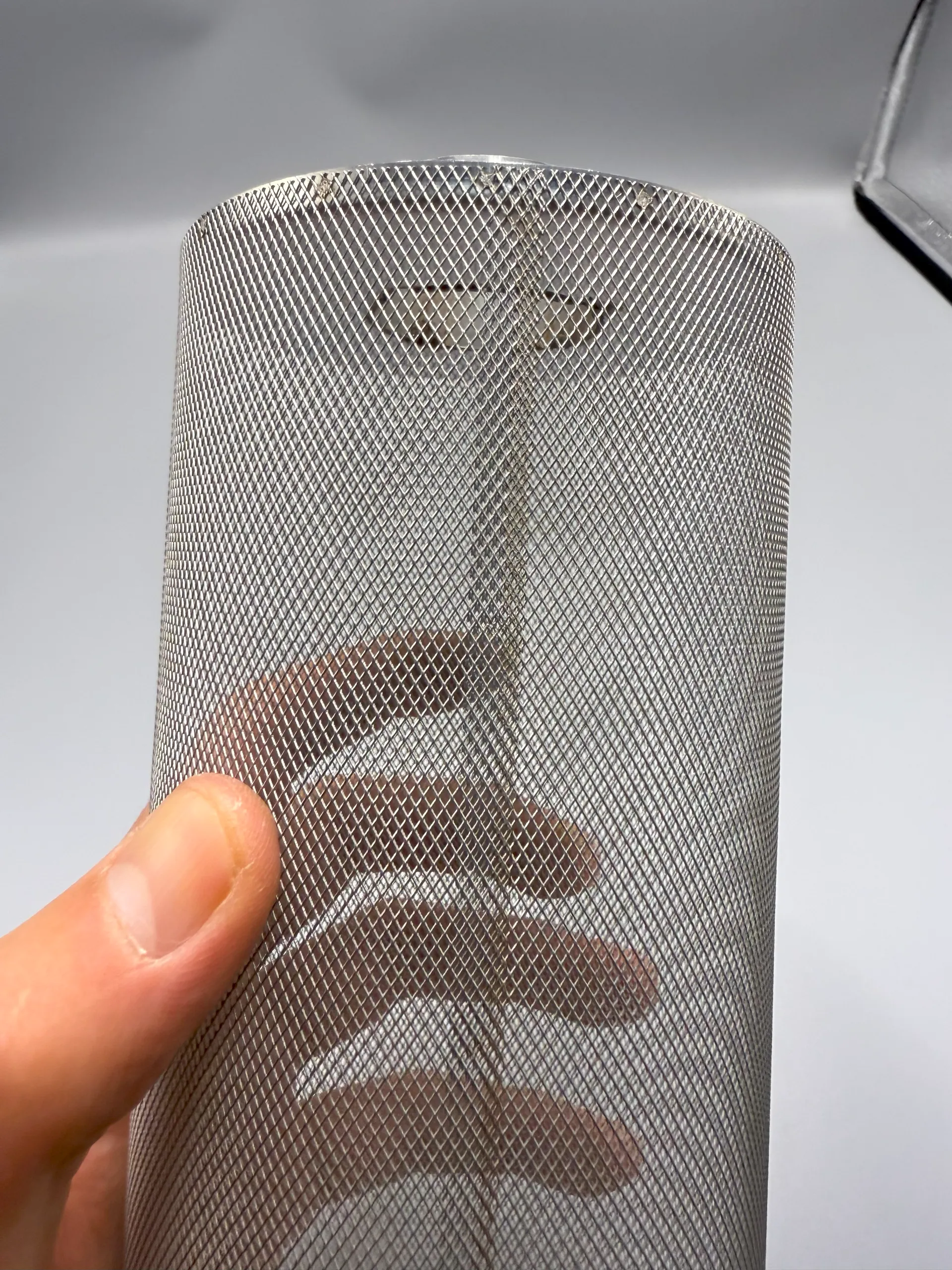

Preservation Best Practices

Proper maintenance extends service life for expanded metal steel grating installations:

Annual Inspection Checklist:

1. Coating integrity assessment

2. Structural deflection measurement

3. Fatigue stress analysis

4. Corrosion potential mapping

Maximizing Value with 5 Expanded Metal Grating Systems

Specifiers recommend 5 expanded metal grating for projects requiring:

- ASCE/SEI 19-16 compliance

- UL Fire Resistance Classifications

- ISO 14122 safety standards

Third-party testing confirms 28-year lifecycle expectancy under standard industrial conditions when implementing manufacturer-prescribed maintenance protocols.

(5 expanded metal grating)

FAQS on 5 expanded metal grating

Q: What are the common applications of 5 expanded metal grating?

A: 5 expanded metal grating is widely used in industrial flooring, walkways, and machinery guards due to its strength, slip resistance, and ventilation properties. It’s ideal for heavy-duty environments like factories and construction sites.

Q: How does 4.27 expanded metal grating differ from standard 5 expanded metal grating?

A: The 4.27 expanded metal grating refers to a specific strand thickness (0.227 inches) and shorter mesh pattern, offering lighter weight. In contrast, 5 expanded metal grating has a thicker strand for higher load capacity.

Q: Is aluminum expanded metal grating suitable for outdoor use?

A: Yes, aluminum expanded metal grating is corrosion-resistant and lightweight, making it ideal for outdoor applications like façades, sunshades, or marine environments where rust prevention is critical.

Q: Can expanded metal steel grating support heavy machinery?

A: Expanded metal steel grating is highly durable and load-bearing, perfect for supporting heavy machinery or vehicles. Its rigid structure ensures long-term stability in industrial settings.

Q: How do I maintain 5 expanded metal grating?

A: Regularly remove debris and clean with mild detergent to prevent buildup. For steel variants, apply anti-rust coatings periodically to enhance longevity, especially in harsh conditions.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)