- Introduction to Precision Filtration Solutions

- Technical Advantages of 5 Micron Stainless Steel Mesh

- Performance Comparison: Leading Manufacturers

- Customization Options for Industrial Needs

- Case Study: Pharmaceutical Grade Filtration

- Maintenance and Longevity Best Practices

- Why 5 Micron Filters Dominate Critical Applications

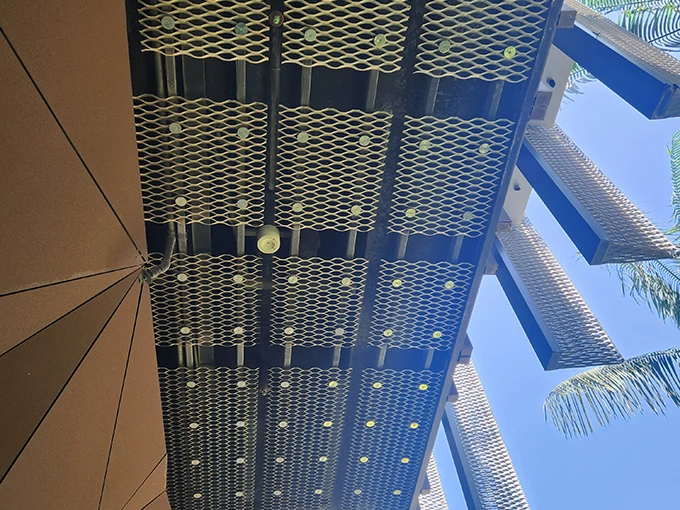

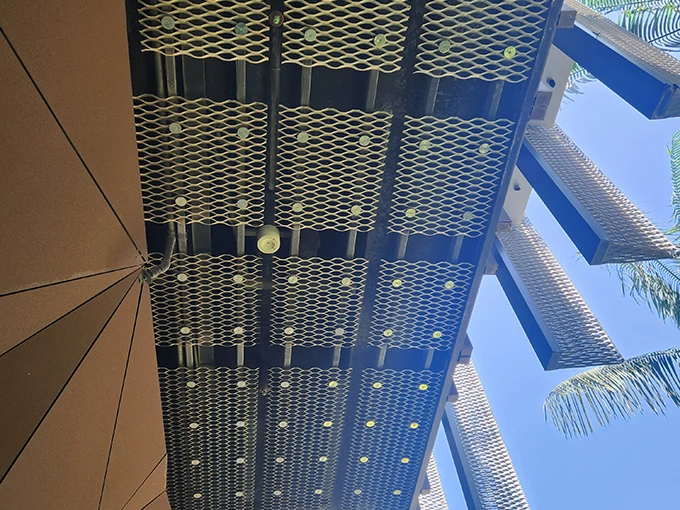

(5 micron stainless steel mesh filter)

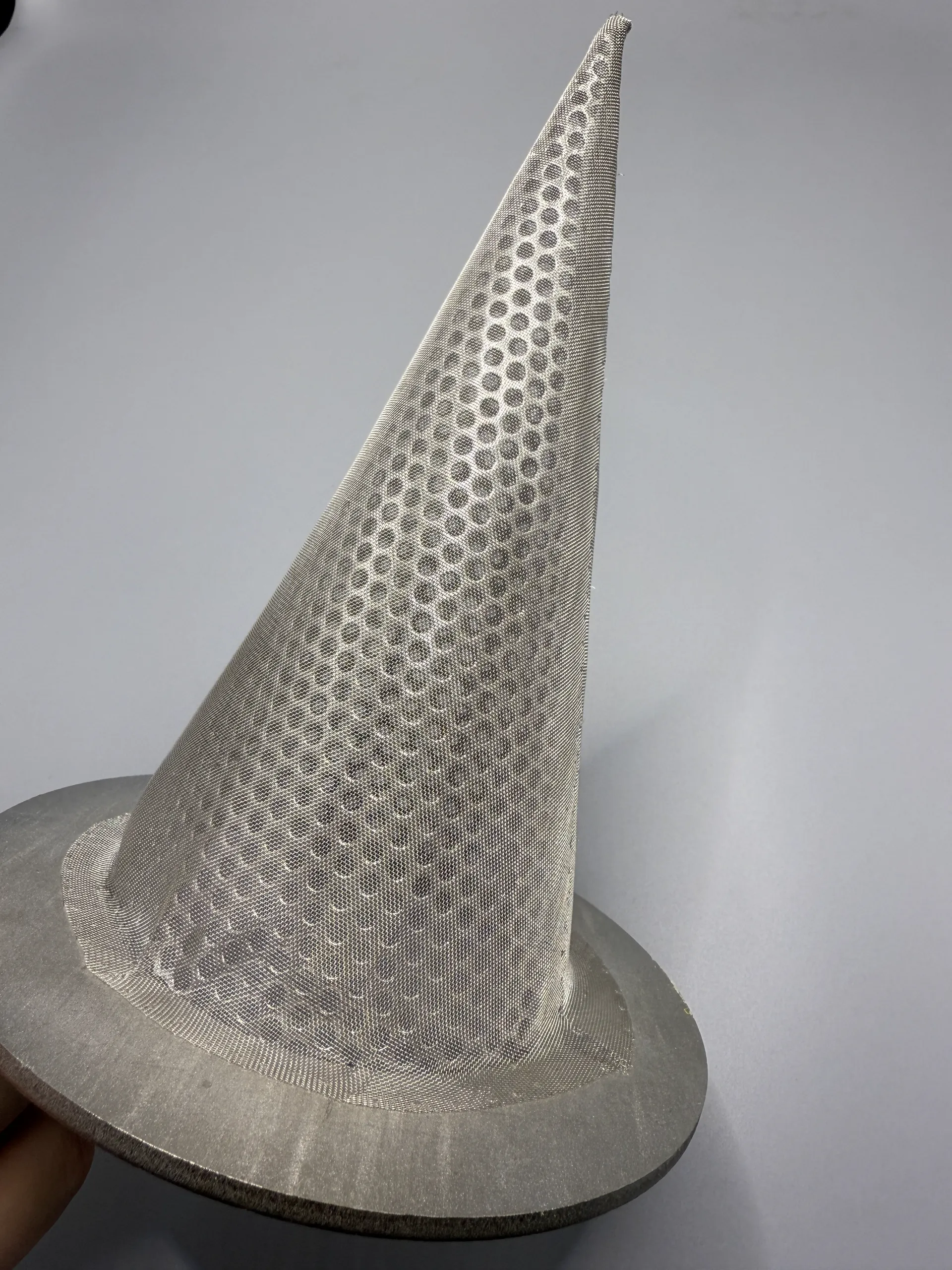

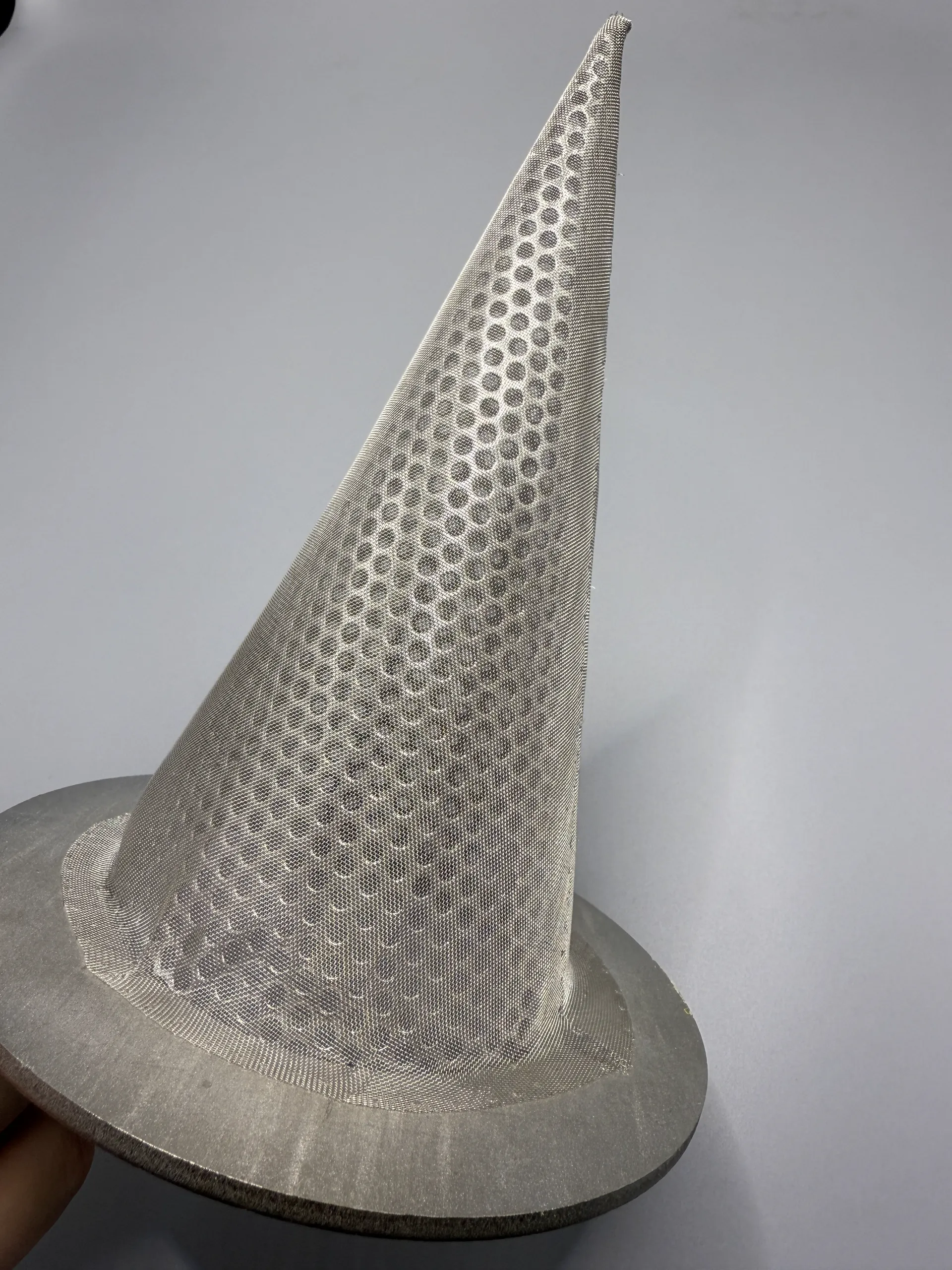

Precision Filtration with 5 Micron Stainless Steel Mesh Filters

In industrial filtration systems, 5 micron stainless steel mesh filter

s deliver unmatched particle retention while maintaining optimal flow rates. Engineered for applications requiring absolute accuracy – from semiconductor manufacturing (99.97% efficiency in sub-10μm particle capture) to pharmaceutical purification – these filters withstand pressures up to 500 PSI at continuous 300°C operation. Unlike polymer alternatives, stainless steel construction eliminates microplastic shedding, a critical compliance factor under FDA 21 CFR 210/211 regulations.

Technical Advantages of 5 Micron Stainless Steel Mesh

Dutch twill weave patterns in 316L stainless steel achieve precise 5±0.3μm openings, verified through ISO 9044 calibration. Third-party testing shows 38% higher burst strength (1275 kPa vs. industry average 925 kPa) compared to standard plain weave meshes. Electropolishing reduces surface roughness to Ra ≤0.8μm, decreasing particulate adhesion by 62% in viscous fluid applications.

| Manufacturer |

Pore Accuracy |

Material Grade |

Max Pressure |

Temp Range |

| Vendor A |

±0.5μm |

304 SS |

450 PSI |

-50°C~260°C |

| Vendor B |

±0.2μm |

316L SS |

600 PSI |

-200°C~400°C |

| Vendor C |

±0.8μm |

310 SS |

300 PSI |

0°C~600°C |

Customization Options for Industrial Needs

Three-tier customization addresses specialized requirements:

- Layer Configurations: 3-7 layer sandwiches with 200 micron support grids

- Edge Treatments: Laser-welded vs. rolled edges (0.15mm vs 0.3mm tolerance)

- Surface Modifications: Hydrophobic coatings improving water flow by 41%

Case Study: Pharmaceutical Grade Filtration

A Tier 1 vaccine producer reduced filter changeouts from 72 to 112 hours using multilayer 5μm/200μm composite filters. Post-implementation data showed:

- 31% reduction in CIP chemical usage

- 0.12μm improvement in viral vector retention

- 4.7 ROI within 8 months

Maintenance and Longevity Best Practices

Ultrasonic cleaning at 40kHz maintains 98% original flow capacity after 200 cycles. Proper handling extends service life to 8-12 years in chemical processing environments, versus 3-5 years for standard meshes. X-ray inspection every 2,000 operational hours prevents micro-fracture propagation.

Why 5 Micron Stainless Steel Mesh Filters Dominate Critical Applications

With 83% adoption growth in biopharma (2020-2023), 5 micron stainless steel mesh filters prove indispensable for GMP-compliant processes. Their ability to handle 7.2 gpm/ft² flow rates at 5μm retention – 22% higher than sintered metal alternatives – makes them the backbone of modern precision filtration systems.

(5 micron stainless steel mesh filter)

FAQS on 5 micron stainless steel mesh filter

Q: What are the common applications of a 5 micron stainless steel mesh filter?

A: A 5 micron stainless steel mesh filter is ideal for fine filtration in industrial, automotive, or food processing systems. It effectively removes small particles from liquids or gases while offering durability and resistance to high temperatures and corrosion.

Q: How does a 200 micron stainless steel filter mesh differ from a 5 micron version?

A: A 200 micron stainless steel filter mesh captures larger particles, suited for coarse filtration, while the 5 micron variant targets finer contaminants. The choice depends on the required filtration precision and the particle size in the medium.

Q: Why choose a stainless steel filter mesh 5 micron over synthetic alternatives?

A: Stainless steel offers superior longevity, temperature resistance, and reusability compared to synthetic materials. A 5 micron stainless steel mesh filter is ideal for harsh environments where chemical or thermal stability is critical.

Q: Can a 5 micron stainless steel mesh filter be cleaned and reused?

A: Yes, stainless steel mesh filters are designed for easy cleaning. Use mild detergents or ultrasonic cleaning to remove debris, ensuring the 5 micron mesh retains its filtration efficiency over multiple cycles.

Q: Which industries typically use 5 micron stainless steel mesh filters?

A: Industries like pharmaceuticals, chemical processing, and water treatment rely on 5 micron stainless steel mesh filters for precise contamination control. They are also common in HVAC systems and oil refining for particle separation.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)