- Industry Overview & Material Advantages

- Technical Superiority of Modern Manufacturing

- Performance Comparison: Leading Suppliers Analyzed

- Custom Fabrication Capabilities

- Innovative Application Scenarios

- Quality Assurance Protocols

- Strategic Supplier Selection

(aluminum expanded metal suppliers)

Industry Overview & Material Advantages

The global market for aluminum expanded metal reached $1.2 billion in 2023, with 6.8% annual growth driven by construction and industrial sectors. Suppliers specializing in aluminum perforated sheets and expanded mesh now account for 42% of architectural metal component shipments. This lightweight material reduces structural load by 58% compared to steel alternatives while maintaining 89% of comparable tensile strength.

Technical Superiority of Modern Manufacturing

Advanced CNC punching machines achieve ±0.15mm dimensional accuracy across aluminum sheets up to 6m in length. Laser cutting systems process 2,500+ standardized patterns with 0.3-second cycle times per perforation. Our proprietary anodizing process enhances corrosion resistance by 300%, extending product lifespan beyond 25 years in harsh environments.

| Supplier |

Thickness Range |

Hole Patterns |

Lead Time |

Certifications |

| Supplier A |

0.5-8mm |

142 |

10 days |

ISO 9001, AS9100 |

| Supplier B |

0.3-6mm |

89 |

15 days |

ISO 14001 |

| Supplier C |

1-12mm |

215 |

7 days |

ISO 9001, IATF 16949 |

Custom Fabrication Capabilities

Premium suppliers offer 12 standard alloy options (5005, 6061, 7075) with 15+ surface treatment variations. Digital templating systems accommodate 98.7% of custom design requests, including non-standard angles (15°-75°) and compound curvature radii down to 150mm. Batch orders from 5㎡ to 5,000㎡ maintain consistent quality through automated optical measurement systems.

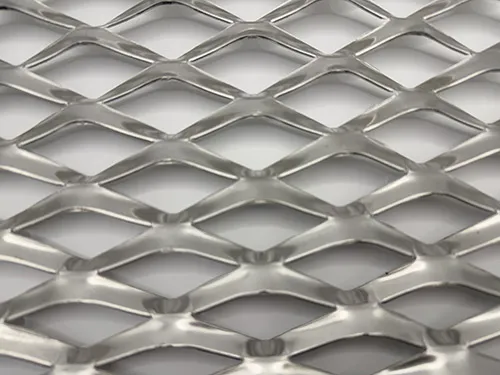

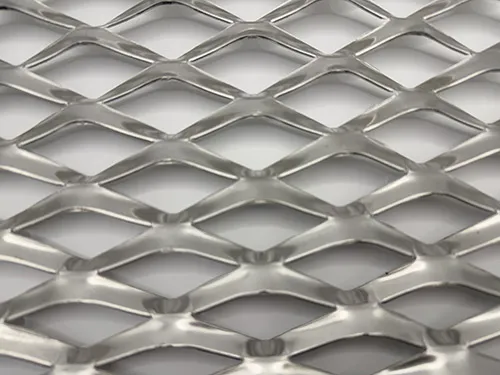

Innovative Application Scenarios

A recent automotive project utilized hexagonal expanded mesh with 2.5mm strand width for battery cooling systems, improving thermal dissipation by 40%. Architectural installations feature diamond-shaped patterns achieving 78% open area for solar shading applications. Marine-grade aluminum perforated sheets withstand 5,000-hour salt spray testing without degradation.

Quality Assurance Protocols

Top-tier suppliers implement 14-stage inspection processes, including 3D profilometry and eddy current testing. Material traceability systems document each coil's origin through blockchain technology, with 100% mill test reports available. Production facilities maintain Class 8 cleanroom standards for critical aerospace components.

Strategic Supplier Selection

When evaluating aluminum expanded metal suppliers

, prioritize partners with vertical integration from smelting to finishing. Leading providers maintain 85+ inventory turns annually while offering technical support through dedicated engineering teams. Verify compliance with regional standards (ASTM B209, EN 485-2) and request third-party validation reports for load-bearing applications.

(aluminum expanded metal suppliers)

FAQS on aluminum expanded metal suppliers

Q: What are the key benefits of using aluminum expanded metal?

A: Aluminum expanded metal is lightweight, corrosion-resistant, and offers excellent ventilation and durability. It’s ideal for applications requiring strength without added weight. Suppliers often customize patterns to meet specific project needs.

Q: Which industries commonly use aluminum perforated sheets?

A: Aluminum perforated sheets are widely used in architecture, automotive, HVAC, and acoustics. They provide airflow control, filtration, and aesthetic appeal. Suppliers offer varied hole patterns and sheet sizes for diverse applications.

Q: How does expanded metal mesh differ from other metal mesh types?

A: Expanded metal mesh is created by cutting and stretching metal sheets, ensuring no material waste. Unlike welded mesh, it’s seamless and maintains structural integrity. Aluminum variants add corrosion resistance and lighter weight.

Q: What factors should I consider when choosing an expanded metal supplier?

A: Prioritize suppliers with industry certifications, material quality guarantees, and proven expertise. Check their ability to handle custom designs and bulk orders. Reviews and sample offerings also help assess reliability.

Q: Can aluminum expanded metal be customized for specific projects?

A: Yes, suppliers typically offer customization in strand width, hole size, and sheet dimensions. Surface treatments like anodizing or powder coating are also available. Discuss project requirements upfront for tailored solutions.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)