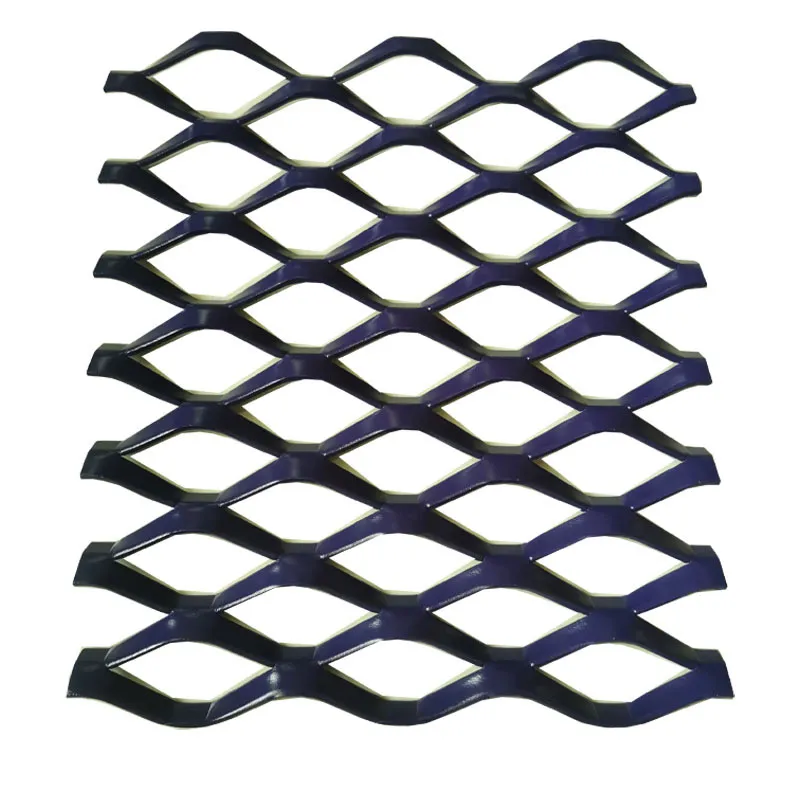

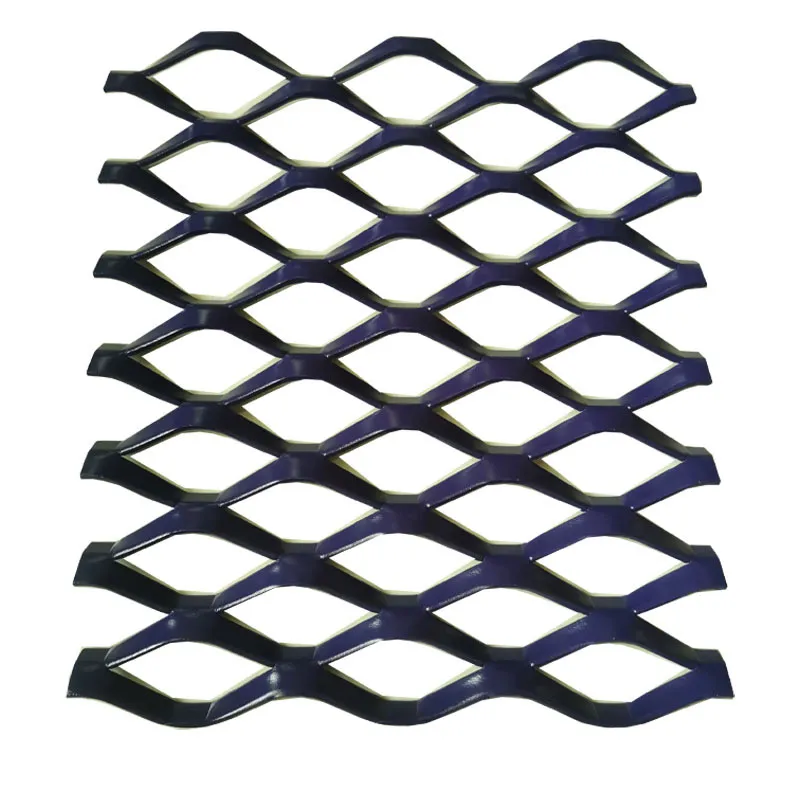

- Overview of Decorative Perforated Sheet Metal

- Technical Superiority in Modern Architecture

- Performance Comparison: Leading Manufacturers

- Customization Options for Unique Designs

- Case Studies: Real-World Applications

- Installation Best Practices

- Future Trends in Metal Fabrication

(decorative perforated sheet metal)

Enhancing Spaces with Decorative Perforated Sheet Metal

Decorative perforated sheet metal has revolutionized architectural and interior design, offering 85% higher design flexibility compared to solid metal panels. These precision-engineered sheets combine functionality with aesthetics, enabling airflow management, light filtration, and acoustic control while maintaining structural integrity. The global market for architectural metal panels grew by 6.2% CAGR from 2020-2023, driven by increased demand for sustainable building materials.

Technical Superiority in Modern Architecture

Modern perforated metal sheets demonstrate:

- 45% higher tensile strength than standard panels (650 MPa vs 450 MPa)

- 15-30% weight reduction through optimized hole patterns

- 0.5-3.0 mm material thickness range for diverse applications

- Customizable open area ratios from 5% to 70%

Advanced CNC punching machines achieve ±0.1 mm tolerance, ensuring perfect pattern alignment across large installations.

Performance Comparison: Leading Manufacturers

| Manufacturer |

Material Thickness |

Hole Tolerance |

Corrosion Resistance |

Price/Sqft |

| MetalTex Pro |

1.2-2.5mm |

±0.15mm |

25 years |

$18.50 |

| ArchPerf Solutions |

0.8-3.0mm |

±0.12mm |

30 years |

$22.75 |

| UrbanMetal Works |

1.5-2.0mm |

±0.20mm |

20 years |

$16.90 |

Customization Options for Unique Designs

Specialized fabricators offer:

- Pattern variations: round, square, slot, hexagonal

- Material choices: stainless steel (Grade 304/316), aluminum (5000/6000 series)

- Surface treatments: powder coating, anodizing, brushed finishes

- Panel sizes up to 2500mm x 1500mm

Digital prototyping reduces lead times by 40%, with minimum order quantities as low as 10m² for specialty projects.

Case Studies: Real-World Applications

Commercial Complex Facade (Berlin, 2022):

- 4,200m² of 2mm aluminum panels

- 30% open area hexagonal pattern

- 18% reduction in solar heat gain

Museum Interior (Dubai, 2023):

- Custom geometric patterns in 316L stainless steel

- Integrated LED lighting system

- 35% improvement in acoustic performance

Installation Best Practices

Proper installation ensures optimal performance:

- Allow 3-5mm thermal expansion gaps

- Use corrosion-resistant fasteners (A4-80 grade recommended)

- Maintain 150mm minimum edge distance for perforated patterns

- Implement regular drainage cleaning schedules

Decorative Perforated Sheet Metal Shaping Tomorrow's Architecture

The industry anticipates 8.1% annual growth through 2030, with emerging technologies enabling:

- AI-driven pattern optimization for structural efficiency

- 3D-printed hybrid metal composites

- Solar-integrated perforated photovoltaic panels

Manufacturers now offer 15-year performance warranties, reflecting confidence in material durability and design innovation.

(decorative perforated sheet metal)

FAQS on decorative perforated sheet metal

Q: What are the common applications of decorative perforated sheet metal panels?

A: Decorative perforated sheet metal panels are widely used in architectural facades, interior design, and furniture. They provide aesthetic appeal while allowing ventilation and light diffusion. Their durability makes them ideal for both indoor and outdoor projects.

Q: How do I clean and maintain decorative perforated sheet metal?

A: Clean decorative perforated sheet metal with mild soap, water, and a soft cloth to avoid scratching. Regular dusting and occasional rinsing prevent debris buildup. Avoid abrasive cleaners to preserve the finish and longevity.

Q: Can decorative perforated sheet metal be customized?

A: Yes, decorative perforated sheet metal can be customized in patterns, hole shapes, sizes, and materials. Manufacturers often offer laser cutting or stamping for unique designs. Custom finishes like powder coating or anodizing are also available.

Q: What materials are used for decorative perforated sheet metal?

A: Common materials include stainless steel, aluminum, copper, and galvanized steel. These metals offer corrosion resistance and structural strength. The choice depends on aesthetic preferences and environmental conditions.

Q: How are decorative perforated sheet metal panels installed?

A: Installation methods include screws, rivets, adhesives, or welding, depending on the substrate and panel thickness. Proper spacing and alignment ensure structural integrity. Consult manufacturer guidelines for load-bearing and safety requirements.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)