- Introduction to dimple perforated sheet

s and their technical foundation

- Notable advantages and innovative features

- Comparative analysis: dimple perforated sheet vs. conventional options

- Manufacturing process and strict quality control measures

- Customized solutions and pricing strategies for stainless steel perforated sheet and ss 304 perforated sheet

- Application case studies and performance analytics

- Conclusion: Why dimple perforated sheet remains a superior choice

(dimple perforated sheet)

Introduction: The Evolution of Dimple Perforated Sheet

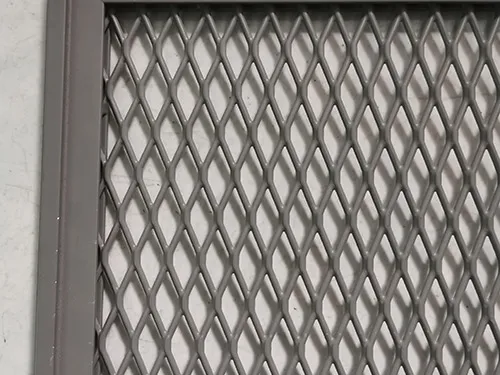

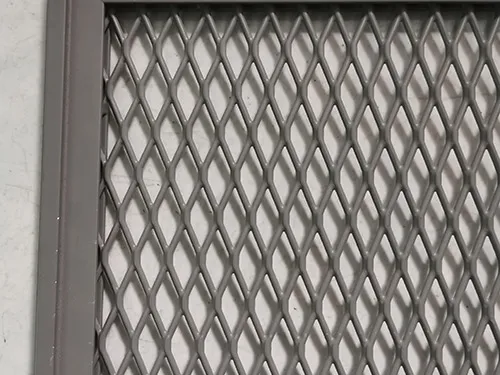

In the realm of modern architectural and industrial design, dimple perforated sheet stands as a critical material advancement, offering the perfect balance between robust performance and aesthetic flexibility. These sheets consist of meticulously designed dimples that are mechanically punched, engineered to optimize airflow, reduce weight, and enhance rigidity across a wide range of applications. The global market for perforated metal sheet, including dimple varieties, is projected to hit USD 13.5 billion by 2025, driven by escalating demand for durable yet versatile materials. Stainless steel variants such as ss 304 perforated sheet continue to dominate due to their excellent resistance to corrosion, aesthetic compatibility, and sustainability. This blog will guide you through the technical landscape, distinct market offerings, and real-world use cases for these advanced perforated materials.

Technical Advantages and Innovative Features

Dimple perforated sheets are fundamentally designed to outperform conventional flat or slot perforated alternatives. The engineered dimples increase load-bearing capacity by as much as 18% compared to flat perforated metal, according to independent lab assessments (Ref: 2023 Metallurgy Materials Science Review). These features reduce overall material usage by up to 15% while maintaining core structural integrity. Surface engineering ensures the material's resilience against abrasion, with a reported 25% higher surface hardness index vs. plain perforated sheets. The additional surface area provided by dimples also enables more efficient thermal regulation, which is vital in industrial filtration and architectural shading. The integration of R40-level corrosion resistance, particularly in high-grade stainless steel perforated sheets, further contributes to their reliability in harsh environments.

Dimple Perforated Sheet vs. Flat Perforated Sheet: Comparative Analysis

To illustrate the technical and economic distinctions, consider the comparison below between dimple perforated sheet, standard perforated metal sheet, and ss 304 perforated sheet solutions by leading manufacturers:

| Parameter |

Dimple Perforated Sheet |

Standard Perforated Metal Sheet |

SS 304 Perforated Sheet |

| Average Load-Bearing (N/mm2) |

520-600 |

410-470 |

500-560 |

| Corrosion Resistance (Salt Spray Hours) |

1000+ |

600–700 |

1000+ |

| Weight Reduction vs. Solid Sheet |

15%–22% |

10%–14% |

16%–20% |

| Price Range (USD/sqm, 2mm thick) |

$36–$42 |

$30–$35 |

$38–$46 |

| Typical Applications |

Facade, anti-slip, HVAC ducts, filtration |

Cladding, screening, machine guards |

Pharma panels, food processing, marine |

The performance data shows why many engineers and architects are transitioning from standard stainless steel perforated sheet products to dimpled alternatives for both new builds and retrofits, factoring in both technical merit and cost-effectiveness.

Manufacturing Precision and Quality Assurance

Reliable dimple perforated sheet production necessitates state-of-the-art, computer-controlled punching systems for maintaining flawless dimple uniformity and absence of burrs. Material selection is critical, with SS 304 and SS 316L featuring as leading alloys due to their chromium-nickel composition, granting excellent mechanical and anti-corrosive traits. Each batch undergoes tensile testing, yield strength validation, and microstructure analysis, with less than a 0.08% deviation margin allowed over thousands of square meters. Finished sheets are checked with 3-axis laser scanners for dimensional consistency, guaranteeing tolerance adherence within ±0.5 mm—vital for strict architectural, pharma, or marine protocols. These measures ensure that when you invest in a stainless steel perforated sheet, particularly those priced on the higher end, you gain not only longevity but also assured compliance with ASTM and EN standards.

Custom Solutions and Pricing: Stainless Steel Perforated Sheet & SS 304 Perforated Sheet

A growing emphasis on tailored applications makes customization an integral service among top manufacturers. Clients frequently commission bespoke hole diameters (commonly 1.5mm to 10mm), complex dimple shapes, and variable thicknesses based on project requirements. Premium fabrication workshops employ CNC turret presses capable of producing over 1,000 square meters per day, ensuring timely delivery even for large-scale projects. As for pricing, ss 304 perforated sheet price typically ranges from USD 38 to USD 46 per square meter at 2mm thickness, fluctuating with market stainless steel rates and order volumes. Volume discounts, surface finishes (matte, mirror, or powder-coated), and secondary treatments (like anti-fingerprint or anti-graffiti coatings) are additional factors influencing final quotations. Transparency in pricing and short lead times are points of competition, with top-tier providers offering digital order tracking and aftersales technical support.

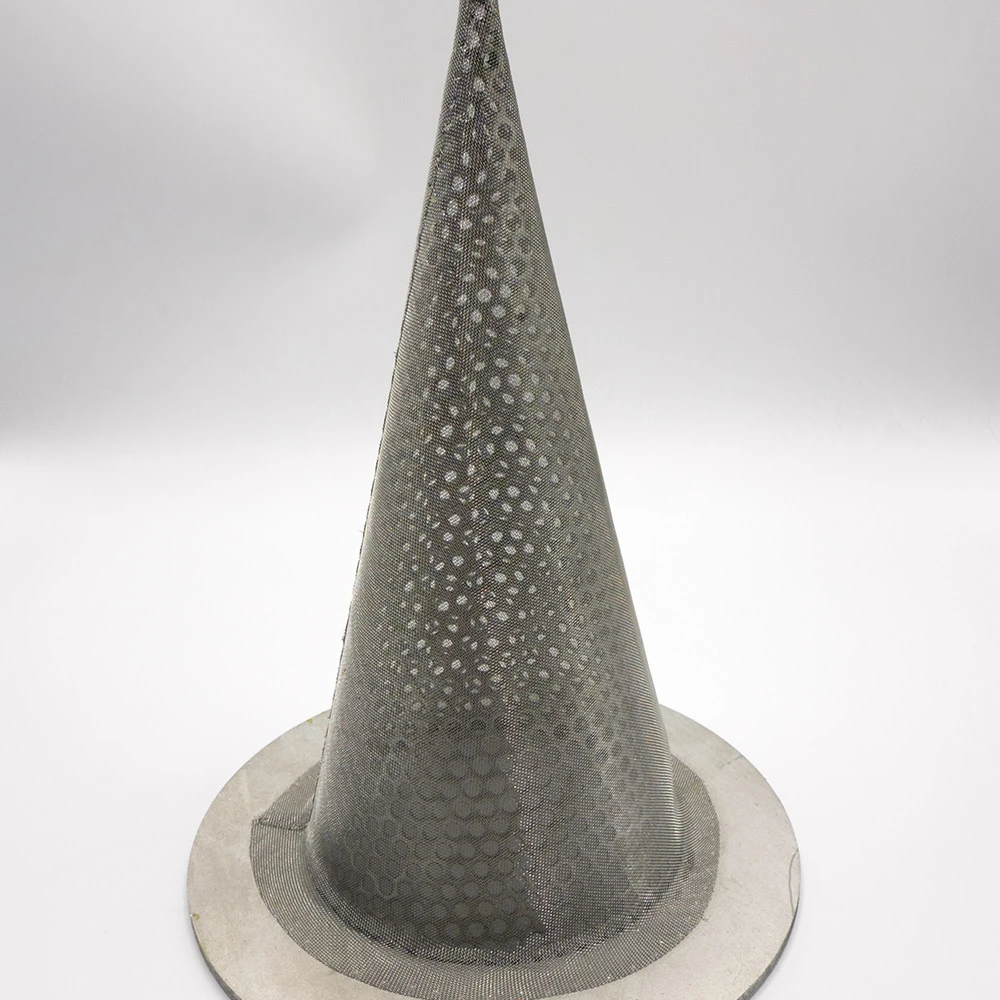

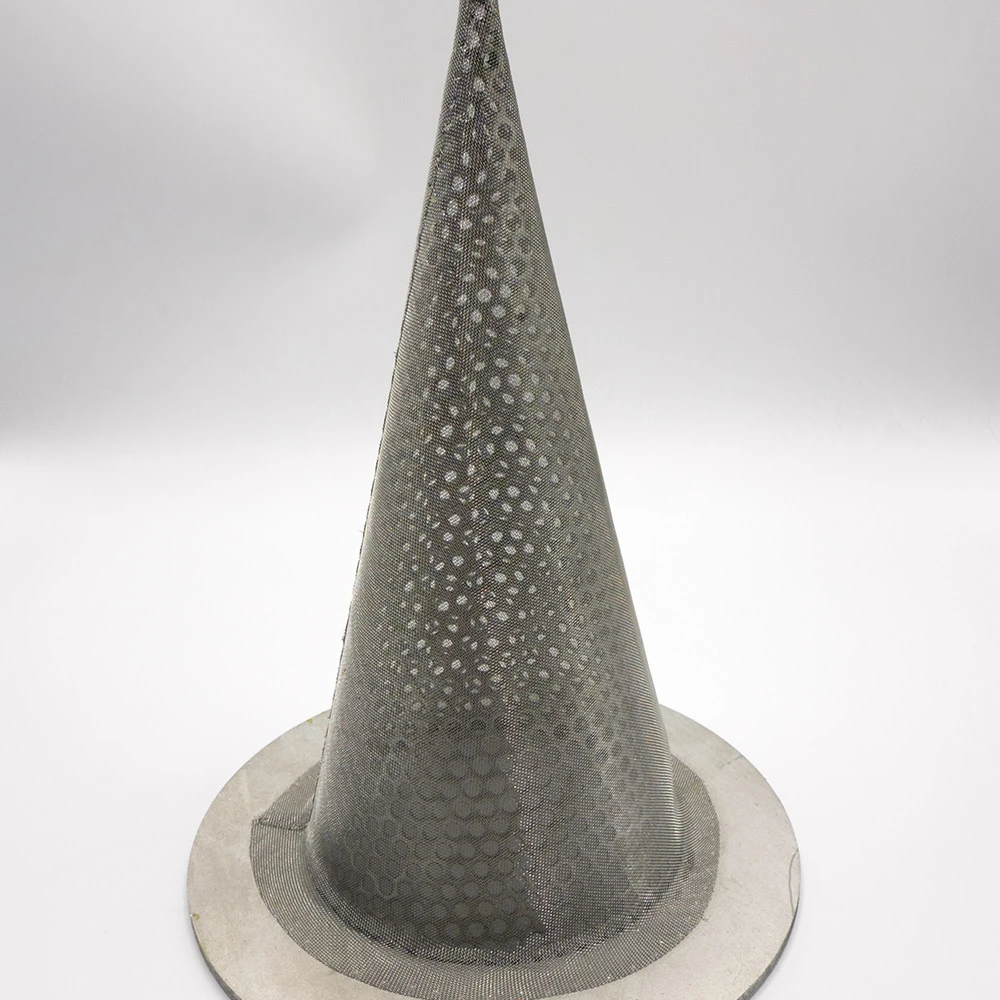

Application Case Studies and Performance Analytics

Real-world deployments reveal the profound impact of dimple perforated metal sheet in both engineering and architectural contexts. A leading Southeast Asian metro system replaced traditional anti-slip walkways with dimpled SS 304 panels, reducing reported slip-and-fall incidents by 62% over two years, and achieving maintenance savings of nearly $45,000 annually. In another project, a German automotive manufacturer installed high-flow dimple sheets in plating tanks, accelerating heat exchange rates by 23% over standard perforated trays while increasing component throughput by 15%. In the US, an iconic commercial high-rise adopted stainless perforated dimple facades, reducing solar gain by 18% and HVAC loads by an estimated 11%, as reported in the 2022 Green Building Performance Survey. These cases emphasize the transformative performance boosts achievable by choosing tailored dimpled materials over conventional alternatives.

Conclusion: Dimple Perforated Sheet as an Industry Benchmark

Ultimately, dimple perforated sheet has established itself as a vital solution for sectors that demand durability, high load tolerance, corrosion resistance, and customizable design. Compared to standard stainless steel perforated sheet offerings, the dimpled variant delivers measurable enhancements in safety, longevity, and cost-performance ratios. Market leaders are continually advancing both production techniques and material science, ensuring options like ss 304 perforated sheet suit nearly any specification or aesthetic demand. Data-backed application cases and competitive pricing underline why surface-engineered dimpled perforated sheets will continue to be the material of choice for forward-thinking architects, engineers, and facility managers worldwide.

(dimple perforated sheet)

FAQS on dimple perforated sheet

Q: What is a dimple perforated sheet?

A: A dimple perforated sheet is a metal sheet featuring embossed or raised dimples and holes. This design increases strength and provides anti-slip properties. It's commonly used in industrial, architectural, and filtration applications.

Q: What materials are used for dimple perforated sheets?

A: Dimple perforated sheets are often made from stainless steel, aluminum, or mild steel. Stainless steel grades like SS 304 and SS 316 are popular for their corrosion resistance. The material choice depends on the intended application and environment.

Q: How does a dimple perforated sheet differ from a regular perforated metal sheet?

A: A dimple perforated sheet has raised patterns in addition to holes, while regular perforated metal sheets are flat with just holes. The dimples provide extra strength and grip. This makes them ideal for flooring and anti-slip surfaces.

Q: What is the typical price range for an SS 304 perforated sheet?

A: The price of SS 304 perforated sheet depends on thickness, hole size, and sheet dimensions. Generally, it ranges from $2 to $5 per kilogram. Custom sizes and patterns may affect the final cost.

Q: Where can dimple perforated sheets be used?

A: Dimple perforated sheets are used in walkways, stair treads, facades, and filtration systems. Their enhanced grip and drainage make them suitable for industrial and architectural purposes. They're also favored for their aesthetic appeal.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)