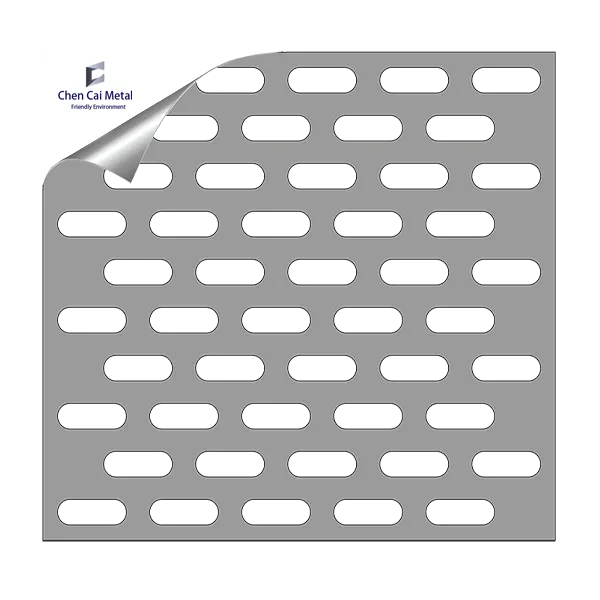

In the demanding landscape of modern industrial processes, the selection of advanced materials and components is paramount for ensuring operational efficiency, safety, and longevity. Among these critical components, the slot hole perforated sheet stands out as a highly specialized material engineered to meet stringent technical requirements across diverse sectors. Its unique slot-shaped apertures provide superior flow characteristics, filtration capabilities, and structural integrity compared to traditional circular perforations. This precision engineering makes it indispensable in applications where exact material separation, controlled fluid dynamics, or optimized air dispersion is essential. The increasing sophistication of industrial processes, coupled with a global push for enhanced sustainability and resource efficiency, is driving a significant surge in demand for high-performance perforated metals. Manufacturers and engineers are continuously seeking innovative solutions that offer extended service life, reduced maintenance, and improved operational output, all of which are core attributes of expertly fabricated slotted perforated sheet products. Understanding the technical nuances, manufacturing processes, and application advantages of these sheets is crucial for industry professionals looking to optimize their system designs and achieve peak performance.

The market for custom perforated metals, particularly those featuring elongated slots, is experiencing robust growth driven by advancements in filtration technology, acoustic management, and architectural design. Industries such as petrochemicals, food processing, water treatment, automotive, and mining increasingly rely on the specialized properties of slot hole perforated sheet to address complex operational challenges. The ability to precisely control the opening size, pattern, and material thickness allows for tailored solutions that deliver specific performance metrics, whether it's enhanced material conveyance, superior sound attenuation, or effective particulate separation. Furthermore, the rising adoption of automation and robotics in manufacturing necessitates components with tighter tolerances and consistent quality, pushing producers of slotted perforated sheet metal to innovate their fabrication techniques. This focus on precision and reliability, combined with the versatility of various alloys such as stainless steel, carbon steel, aluminum, and specialized alloys, positions these sheets as a cornerstone for future industrial development. The integration of digital design tools and advanced manufacturing processes, including CNC punching and laser cutting, further enhances the capabilities for producing intricate and high-precision slot patterns, catering to bespoke project specifications.

The production of a Slot 45° Perforated Sheet, like the one found at https://www.ccmetalmesh.com/slot-45-perforated-sheet.html, is a multi-stage, highly controlled process that begins with the careful selection of raw materials. Typically, high-grade metals such as stainless steel (e.g., SS304, SS316, SS316L), carbon steel, galvanized steel, aluminum, brass, or specialty alloys like Inconel and Hastelloy are utilized, chosen based on the intended application's demands for corrosion resistance, strength, and temperature tolerance. The manufacturing process primarily involves advanced CNC punching or laser cutting technologies, ensuring unparalleled precision and consistency in the slot dimensions and alignment. Unlike casting or forging, which are typically used for bulk metal shaping, perforation relies on removing material from a flat sheet. Initial material preparation includes cleaning and flattening the raw metal coils or sheets to prevent imperfections. The sheets are then loaded onto sophisticated CNC punching machines equipped with custom-designed dies that precisely stamp out the elongated slots, often at a 45-degree angle to the sheet's edge for specific flow dynamics. For more intricate designs or higher precision requirements, fiber laser cutting offers exceptional accuracy without mechanical stress on the material, ideal for thinner gauges or complex patterns.

Following the perforation, the sheets undergo a series of finishing processes to enhance their durability and functional properties. Deburring is a critical step, removing any sharp edges or burrs that could impede flow, cause wear, or pose safety hazards. This can be achieved through mechanical brushing, tumbling, or vibratory finishing. Depending on the material and application, further treatments may include degreasing, passivation (for stainless steel to enhance corrosion resistance), powder coating, anodizing, or galvanizing. Each step contributes to the product's longevity and performance in harsh environments. Quality control is integrated throughout the entire manufacturing process, adhering rigorously to international standards such as ISO 9001 for quality management and ANSI standards for material specifications and testing. Optical inspection systems and precision measurement tools are used to verify slot dimensions, sheet flatness, and material integrity. The service life of a slotted perforated sheet can range from several years to decades, depending on the material, operating environment (e.g., exposure to chemicals, abrasion), and specific application. For instance, a slot hole perforated sheet used in a petrochemical filtration system operating in corrosive media might undergo more frequent inspection and replacement cycles compared to a sheet used for architectural cladding.

In typical applications within the petrochemical industry, slotted hole perforated sheet is often employed in catalyst support grids, reactor internal baskets, and filtration systems, where their precise slot openings prevent the passage of solid particulates while allowing unhindered fluid or gas flow, significantly reducing pressure drop and enhancing energy efficiency. In metallurgical processes, these sheets serve as screening media for precise aggregate sizing and ore separation, minimizing material loss and improving product purity. For water and drainage systems, they are vital components in well screens, filter baskets, and dewatering applications, preventing clogging and ensuring efficient liquid-solid separation, which contributes to substantial energy savings by optimizing pump performance and reducing maintenance downtime. The robust construction and tailored material selection provide exceptional resistance to corrosion, abrasion, and high temperatures, making them ideally suited for these demanding industrial settings. The design versatility of Slot 45° Perforated Sheet, specifically, allows for optimal flow distribution and self-cleaning characteristics, minimizing build-up and extending operational intervals.

The performance of a slot hole perforated sheet is critically dependent on its precise technical specifications. These parameters collectively determine its suitability for specific industrial applications, affecting flow rates, filtration efficiency, structural integrity, and acoustic properties. Key specifications include material type, sheet thickness, slot width, slot length, pitch (distance between slot centers), and the overall open area percentage. The material, as discussed, is selected based on the operating environment's corrosivity, temperature, and mechanical stress. Sheet thickness influences the sheet's rigidity and load-bearing capacity, with thicker gauges typically used in structural applications or where high-pressure differentials are present. Slot width is crucial for filtration and separation, defining the minimum particle size that can pass through. Slot length affects the open area and flow capacity, while pitch determines the pattern density and overall structural strength. The open area percentage, calculated as the ratio of the total area of the perforations to the total area of the sheet, is a fundamental metric for assessing flow capacity and light/air transmission. Higher open area percentages generally result in less pressure drop and greater flow, but may compromise mechanical strength.

To provide a clear understanding of typical product capabilities, the following table outlines common parameters for slotted perforated sheet products, including those similar to the Slot 45° Perforated Sheet. These values represent general industry standards and can be customized to meet unique project requirements. This table serves as a guide for engineers and procurement specialists in selecting the appropriate perforated sheet for their specific needs, emphasizing the versatility and precision achievable with modern fabrication techniques. The integrity of these parameters is consistently validated through rigorous testing protocols, including material composition analysis, dimensional accuracy checks, tensile strength tests, and corrosion resistance evaluations, ensuring compliance with relevant industry benchmarks such as ASTM E331 for water penetration and ASTM B117 for salt spray corrosion resistance. This commitment to data-driven performance metrics is critical for building trust and reliability in B2B partnerships.

| Parameter | Typical Range / Value | Notes on Application |

|---|---|---|

| Material Types | Stainless Steel (304, 316, 316L), Carbon Steel, Galvanized Steel, Aluminum, Brass, Nickel Alloys | Corrosion resistance, strength, cost-effectiveness, weldability, specific chemical compatibility. |

| Sheet Thickness | 0.5 mm to 10 mm (0.02" to 0.4") | Structural integrity, load-bearing capacity, and ease of fabrication. |

| Slot Width (Minimum) | 0.2 mm (0.008") | Fine filtration and precise particle separation. |

| Slot Length (Typical) | 5 mm to 50 mm (0.2" to 2") | Influences open area and flow characteristics. |

| Pitch (Center to Center) | Slot Width + 1 mm to Slot Length + 10 mm | Determines open area and structural stability. Can be straight or staggered. |

| Open Area Percentage | 20% to 60% (customizable) | Flow rate, light/air transmission, and structural integrity balance. |

| Maximum Sheet Size | Up to 2 meters x 6 meters (6.5 ft x 20 ft) | Availability varies by manufacturer and material. Larger sheets reduce fabrication costs. |

The versatility of the slot hole perforated sheet enables its deployment across a vast array of industrial and commercial applications, where precision, durability, and efficient material management are critical. In the food and beverage industry, stainless steel slotted perforated sheet is integral to dewatering, drying, and sorting processes for grains, fruits, and vegetables, ensuring hygienic operations and preventing cross-contamination. Its smooth, non-porous surface facilitates easy cleaning, meeting stringent FDA and HACCP standards. Within the oil and gas sector, these sheets are employed in well screens, sand control systems, and refinery internals, effectively filtering out solids from crude oil and natural gas streams, thereby protecting sensitive downstream equipment from abrasive wear and corrosion. The precise slot opening minimizes pressure drop while maximizing flow, crucial for optimizing energy consumption in pumping operations. Moreover, in architectural applications, the aesthetic appeal of a slotted perforated sheet metal with specific slot patterns can be utilized for building facades, sunscreens, and interior design elements, offering both functional benefits like shading and ventilation, and contributing to the visual design language of modern structures. This wide adaptability underscores their importance in facilitating efficient and reliable industrial operations.

Beyond these examples, slot hole perforated sheet finds extensive use in environmental control systems, including water treatment plants for filtering industrial effluent and municipal wastewater, and in air filtration systems for removing particulates from industrial emissions. Its robust construction ensures long-term performance even in highly corrosive or abrasive environments, reducing the need for frequent replacements and minimizing operational downtime. In the mining industry, heavy-gauge slotted perforated sheet metal is used in vibrating screens for aggregate sizing and mineral separation, providing superior wear resistance and precise classification of materials. For example, a major mining operation reported a 15% increase in screening efficiency after switching to customized stainless steel slotted screens, citing reduced blinding and extended screen life compared to traditional mesh. This tangible improvement translates directly into enhanced productivity and lower operational costs. Furthermore, in the automotive sector, smaller gauge slotted hole perforated sheet is used for exhaust system components, heat shields, and grilles, where its ability to withstand high temperatures and provide effective ventilation is invaluable. These diverse applications highlight the critical role these engineered materials play in driving efficiency and reliability across various global industries.

The bespoke nature of industrial requirements often necessitates custom manufacturing for slot hole perforated sheet products. While numerous manufacturers offer standard sizes and patterns, the true value for B2B decision-makers lies in a provider's ability to deliver tailored solutions that precisely match specific project demands. Customization extends beyond merely altering dimensions; it encompasses the selection of specialized alloys for extreme environments, unique slot configurations for optimized flow or filtration, specific finishes for enhanced corrosion resistance or aesthetics, and even secondary fabrication processes like bending, welding, or rolling to create complex shapes or assemblies. A key differentiator among manufacturers is their engineering expertise and production flexibility. Leading providers possess advanced CAD/CAM capabilities and a diverse range of CNC machinery, enabling them to translate intricate designs into high-precision finished products. They also offer comprehensive technical support, assisting clients with material selection, pattern optimization, and performance prediction based on application-specific data. Companies with a strong track record of successful custom projects and dedicated R&D departments are generally better equipped to handle complex challenges and deliver innovative solutions, setting them apart in a competitive market.

When evaluating manufacturers for slotted perforated sheet, several factors beyond just price should be considered to ensure long-term value and reliability. Quality certifications such as ISO 9001, along with adherence to industry-specific standards (e.g., ASME for pressure vessels, API for oil & gas), are crucial indicators of a manufacturer's commitment to quality and consistency. Experience and service longevity, often measured by years in the industry and the volume of completed projects, provide insights into a company's reliability and understanding of market needs. Reputable manufacturers also offer robust quality assurance protocols, including detailed material traceability, in-process inspections, and final product testing. Customer support, including responsiveness to inquiries, technical assistance, and after-sales service, is equally important. Furthermore, comparing delivery lead times, minimum order quantities, and packaging options can reveal a manufacturer's operational efficiency and ability to meet project deadlines. For instance, a comparison of two hypothetical manufacturers might show one offering slightly higher pricing but significantly shorter lead times and superior post-delivery support, making them the more attractive option for time-critical projects requiring high reliability. This holistic evaluation process is essential for forging successful, long-term partnerships in the specialized field of perforated metal solutions.

Building trust and establishing authority in the B2B sector for specialized products like slot hole perforated sheet hinges on transparent quality assurance, robust warranties, and reliable customer support. A reputable manufacturer will possess comprehensive industry certifications, such as ISO 9001:2015 for quality management systems, and often specific material or process certifications like those from ASTM or DIN standards. They typically engage in rigorous in-house testing, including chemical composition analysis, mechanical property testing (e.g., tensile strength, hardness), and dimensional accuracy checks using advanced optical and laser measurement tools. Some even provide third-party inspection reports or certify compliance with FDA regulations for food-grade applications, further solidifying their authoritative standing. Companies with a long service history, significant investment in R&D, and partnerships with major industrial clients or research institutions demonstrate a deep understanding of industry needs and a commitment to ongoing product innovation. Case studies and client testimonials, detailing successful applications of their slotted perforated sheet products in challenging environments, serve as powerful evidence of their experience and reliability.

For businesses investing in high-value components, a clear and comprehensive warranty is non-negotiable. Leading manufacturers of slotted perforated sheet metal typically offer warranties covering material defects and manufacturing flaws for a specified period, often ranging from 1 to 5 years, contingent on proper installation and use. This warranty reflects the manufacturer's confidence in their product's durability and performance. Details regarding the average delivery cycle are also crucial for project planning; most custom orders can be fulfilled within 3-6 weeks, depending on complexity and material availability, with express options sometimes available for urgent needs. Furthermore, exceptional customer support is a cornerstone of trustworthiness. This includes readily available technical assistance for product selection, design consultation, and troubleshooting, as well as efficient handling of inquiries and after-sales service. A well-structured FAQ (Frequently Asked Questions) section, addressing common queries about material properties, design considerations, installation, and maintenance, can significantly enhance user confidence and demonstrate a manufacturer's commitment to transparency and customer education.

Slot holes offer higher open area for a given strength, leading to improved flow rates and reduced pressure drop in fluid and air handling applications. Their elongated shape also provides superior material separation in screening processes, preventing blinding and allowing for more efficient material classification, especially for long or fibrous particles. The specific 45-degree angle in Slot 45° Perforated Sheet can further optimize directional flow and self-cleaning capabilities.

Corrosion resistance is primarily achieved through material selection. For highly corrosive environments, stainless steel grades (e.g., 316L), nickel alloys (e.g., Hastelloy, Inconel), or titanium are recommended. Further protection can be provided through surface treatments such as passivation for stainless steel, hot-dip galvanizing for carbon steel, or specialized coatings like epoxy or powder coating, which create a barrier against corrosive agents. Manufacturers provide guidance based on the chemical and environmental exposure.

Absolutely. Customization is a core offering for most professional manufacturers. This includes precise control over material type, sheet dimensions, slot size (width and length), pitch, pattern (straight, staggered, specific angle like 45°), and finishing processes. Manufacturers often work with clients' engineering teams to develop bespoke designs that meet specific performance criteria, load requirements, and aesthetic preferences. This flexibility ensures optimal performance for niche applications.

The service life of a slot hole perforated sheet varies significantly based on material, operating conditions (temperature, pressure, chemical exposure, abrasion), and maintenance practices. High-grade stainless steel or specialty alloys in moderate environments can last for decades. In highly aggressive or abrasive environments, the lifespan might be shorter, requiring more frequent inspection and replacement. Manufacturers provide estimates based on material data and application specifics, often backed by industry case studies and accelerated aging tests.

The continuous evolution of industrial processes demands materials that offer unparalleled precision, durability, and adaptability. The slot hole perforated sheet stands as a testament to this need, providing engineered solutions that optimize flow dynamics, enhance filtration efficiency, and contribute to the structural integrity of complex systems across a multitude of sectors. From the demanding environments of petrochemical refineries and mining operations to the precise requirements of food processing and architectural design, its unique properties deliver tangible benefits, including improved energy efficiency, extended equipment lifespan, and reduced maintenance costs. The commitment to stringent manufacturing processes, adherence to international quality standards like ISO and ANSI, and the capability for extensive customization underscore the product's reliability and versatility. As industries continue to innovate and seek more sustainable and efficient solutions, the role of high-performance perforated metals, especially those with specialized slot geometries like the Slot 45° Perforated Sheet, will only grow in importance, solidifying its position as an indispensable component in advanced industrial applications worldwide.

PREV:

This is the last article