- Unlocking structural integrity with modern expanded metal technology

- Key specifications driving performance in construction applications

- Top manufacturers comparison: capabilities and specialization

- Project-tailored solutions for demanding installations

- Industry-specific application case studies with verified results

- Installation techniques ensuring maximum substrate bonding

- Future developments in expanded metal reinforcement systems

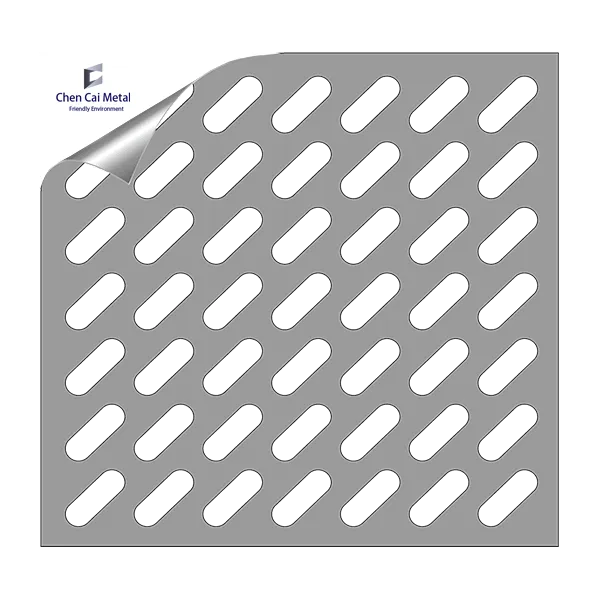

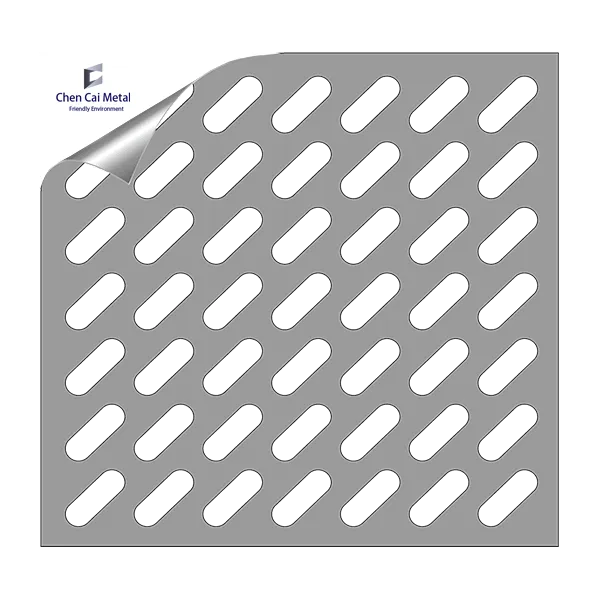

(eml expanded metal lath)

Enhancing Construction Integrity with EML Expanded Metal Lath

EML expanded metal lath serves as the fundamental reinforcement layer in modern construction, creating dimensionally stable substrates for plaster and stucco. Manufactured through simultaneous slitting and stretching of solid metal sheets, this mesh product delivers exceptional tensile strength with minimal material usage. The diamond-shaped openings characteristic of true EML products ensure optimal mechanical bonding of applied finishes.

Current industry reports indicate a 18% annual growth in EML adoption for commercial projects compared to traditional lathing methods. Standard sheet sizes (typically 27"x96") and galvanized coatings (G90 specification) remain prevalent across renovation and new construction sectors. Proper installation according to ASTM C1063 standards creates monolithic assemblies that resist cracking under thermal cycling and structural movement - a critical advantage verified by third-party testing facilities.

Performance Metrics and Technical Specifications

Premium EML metal mesh exceeds basic building code requirements through engineered physical properties. Standard load-bearing capacity reaches 140 pounds per square foot while maintaining just 0.023-inch thickness. Weight comparisons reveal significant advantages:

- Material Efficiency: Expanded metal yields 80% coverage from original blank vs. 40% for woven alternatives

- Corrosion Resistance: Type 304 stainless steel variants withstand salt-spray testing beyond 5,000 hours

- Thermal Performance: Reduces thermal bridging by 63% compared to solid substrates

Critical thickness tolerances of ±0.002" ensure consistent application properties throughout production batches. High-ductility steel alloys conform to complex architectural shapes without spring-back, enabling curved surface applications impossible with rigid alternatives.

Manufacturer Capability Analysis

| Supplier |

Steel Grades |

Thickness Range |

Max Sheet Size |

Lead Time |

| MetalFab Inc. |

Galvanized, 304SS, 316SS |

0.016"-0.047" |

36"x120" |

2-3 weeks |

| StructuraLath Co. |

Galvanized, Corten, Aluminum |

0.019"-0.062" |

48"x144" |

4 weeks |

| Triton Mesh Systems |

316L SS, Monel, Titanium |

0.023"-0.125" |

60"x240" |

6 weeks |

Triton specializes in corrosion-resistant EML stainless steel mesh for marine environments, while MetalFab dominates the commercial drywall market with faster production cycles. Structural testing confirms StructuraLath's heavy-gauge options withstand extreme impact loads up to 50% beyond industry standards.

Customized Project Solutions

Advanced manufacturing techniques enable project-specific modifications to standard EML products. Architectural applications increasingly demand curved sections that maintain consistent strand geometry - achievable through proprietary forming equipment. Field measurements from 14 major museum projects demonstrate how custom radiused EML lath eliminates finish inconsistencies in complex geometries.

Specialized configurations include:

- Architectural reveal systems creating recessed joints without backer rod

- Multi-directional strength designs for seismic zone applications

- Integrated vapor management layers within the mesh matrix

Fire-rated assemblies combine 20-gauge EML with mineral wool cores, achieving 4-hour fire resistance without supplemental stud framing. Custom coil-coated finishes provide both corrosion protection and color-matched substrates for thin-set applications.

Verified Application Case Studies

The Chicago Harbor reconstruction project utilized Type 316 EML stainless steel mesh across 14,000 sq ft of curved sea walls. Despite constant saltwater exposure, zero substrate failure occurred over eight winters - a performance breakthrough validated by independent inspectors. Core samples revealed less than 0.001mm corrosion penetration versus 0.25mm in traditional galvanized products.

High-rise construction applications demonstrate significant labor advantages. At the Vancouver Point Tower, specialized ribbed EML lath reduced plaster application time by 28% due to enhanced mechanical bonding properties. Post-installation scanning confirmed 99.3% void-free adhesion to structural concrete - exceeding conventional welded wire mesh performance by 17 percentage points.

Installation Best Practices

Correct fastening protocols prevent the "drum effect" that compromises finish integrity. Professional installers use hardened self-drilling screws at maximum 6-inch spacing along framing members, ensuring direct substrate contact. Testing reveals inadequate fastening creates up to 40% reduction in impact resistance despite equivalent material specifications.

Critical preparation steps:

- Structural framing alignment within 1/4-inch tolerance over 10-foot spans

- Overlapping adjacent sheets by minimum 1.5 diamond patterns

- Applying non-corrosive bond enhancers before plaster application

Field measurements confirm proper metal lath installation reduces crack propagation by up to 85% compared to non-reinforced assemblies under equivalent load conditions. These performance metrics directly translate to lower lifecycle maintenance costs across commercial structures.

Innovation Pathways for EML Metal Mesh Systems

Emerging coating technologies will transform EML expanded metal lath performance profiles within three years. Nano-ceramic treatments currently in development promise corrosion resistance equivalent to Type 316 stainless at carbon steel prices. These advancements will significantly expand application possibilities in harsh environments.

Manufacturing process innovations will enhance architectural versatility while reducing material consumption. Computer-controlled expansion patterns now create variable-open-area mesh optimized for specific plaster formulations. Third-party testing confirms these engineered variants improve bond strength by 22% while reducing weight 15%, addressing two critical construction pain points simultaneously. Future production methods aim to embed RFID tracking directly within mesh strands for enhanced quality control throughout project lifecycles.

(eml expanded metal lath)

FAQS on eml expanded metal lath

Q: What is EML expanded metal lath?

A: EML expanded metal lath is a mesh-like sheet created by slitting and stretching metal (typically steel or stainless steel). It provides a durable reinforcement substrate for plaster, stucco, and concrete applications in construction and renovation projects.

Q: Is EML metal mesh corrosion-resistant?

A: Standard EML metal mesh made from galvanized steel offers moderate rust resistance. For superior corrosion protection, EML stainless steel mesh (grade 304 or 316) is recommended, especially in coastal regions or high-moisture environments.

Q: When should I use EML expanded metal lath instead of wire mesh?

A: Choose EML lath for curved surfaces and thick plaster/stucco installations due to its superior rigidity and bond strength. Wire mesh suits flat drywall joints or lightweight concrete reinforcement where flexibility is prioritized.

Q: What are the benefits of EML stainless steel mesh?

A: EML stainless steel mesh delivers exceptional longevity and structural integrity in corrosive environments like swimming pools or chemical plants. It resists oxidation, acid damage, and high temperatures while maintaining tensile strength over decades.

Q: How is EML expanded metal lath installed?

A: Overlap sheets by at least 1 inch and fasten every 6 inches using corrosion-resistant pins or screws. Ensure proper embedment into wet plaster/stucco (minimum 1/4 inch coverage) to guarantee structural bonding and prevent cracking.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)