- Introduction to Expandable Metal Solutions

- Technical Advantages of Expandable Metal Sheets

- Performance Comparison: Leading Manufacturers

- Customization Options for Industrial Needs

- Real-World Applications Across Industries

- Cost Efficiency and Sustainability Metrics

- Future Trends in Expandable Steel Innovation

(expandable metal)

Unlocking the Potential of Expandable Metal Solutions

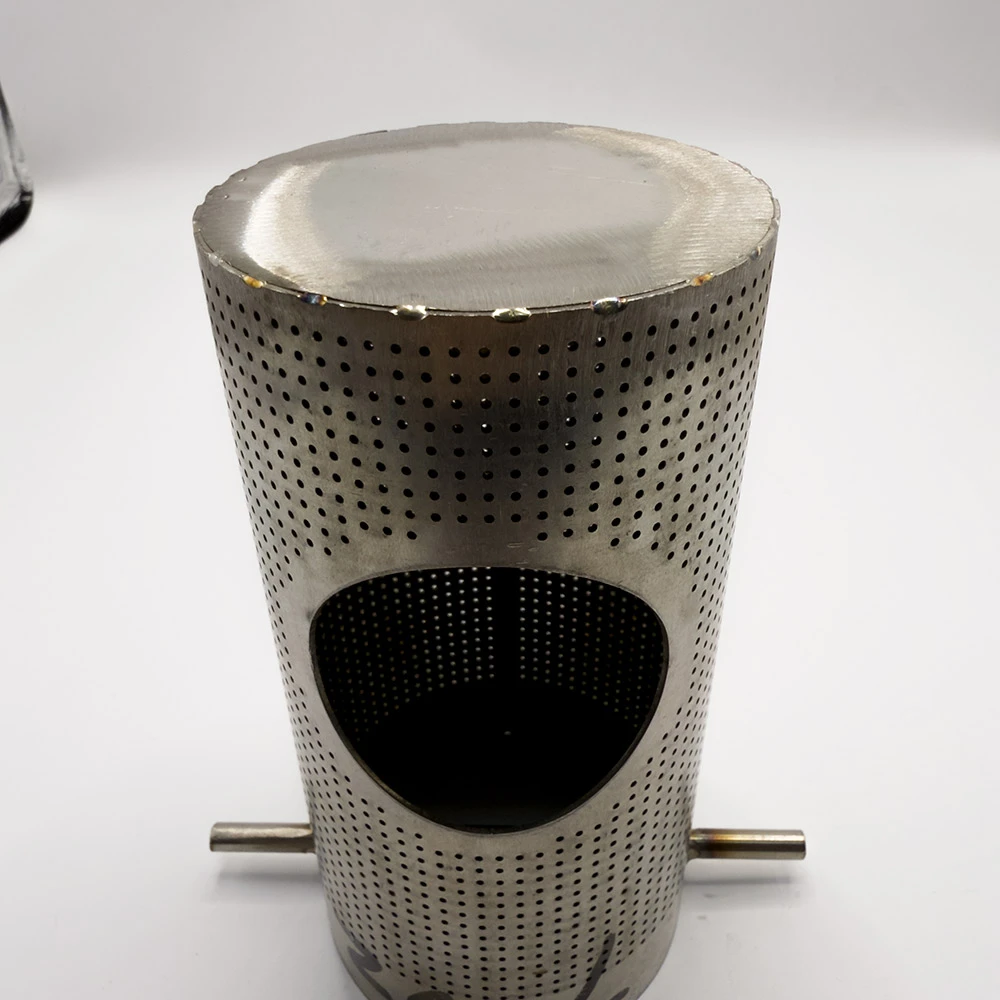

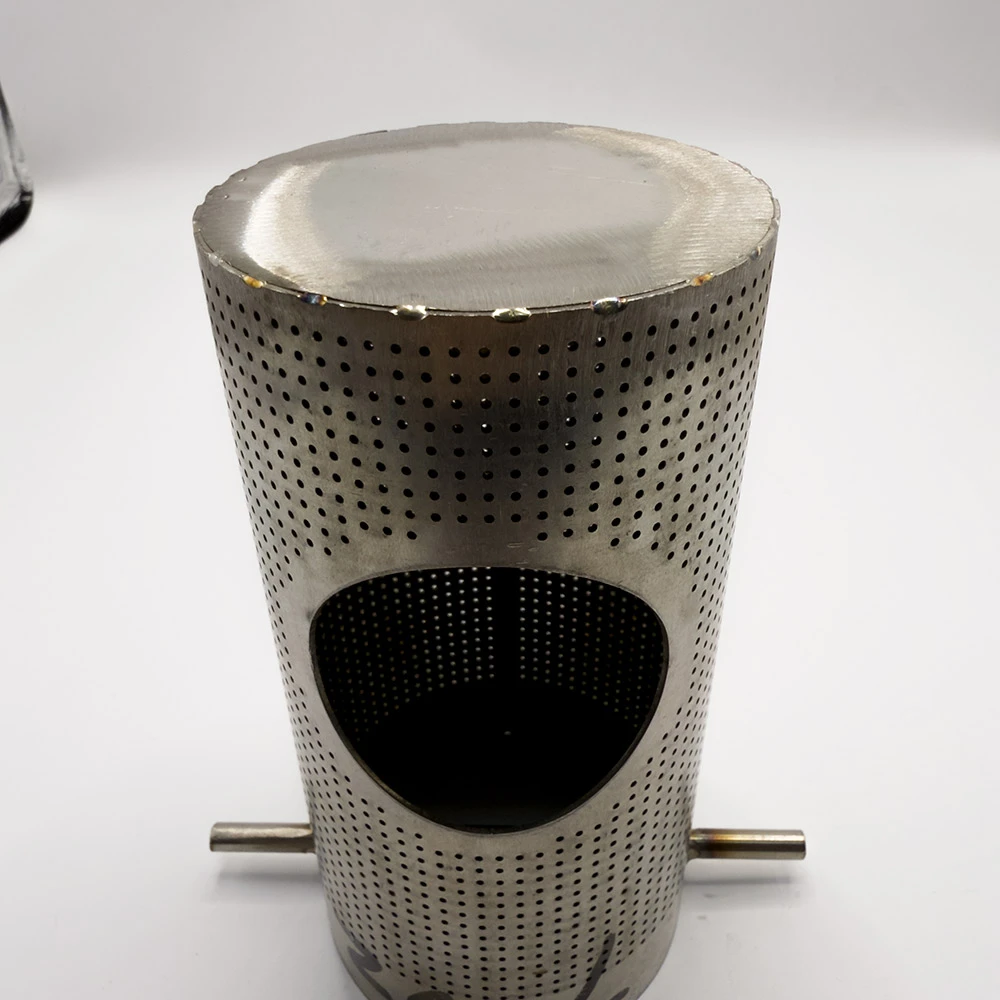

Expandable metal, a versatile material engineered through precise stamping and stretching processes, has become indispensable in modern manufacturing. With a global market growth rate of 6.2% CAGR (2023-2030), industries increasingly rely on expandable steel sheets for structural and functional advantages. These perforated materials offer unique combinations of strength-to-weight ratios, airflow optimization, and design flexibility unmatched by solid alternatives.

Technical Advantages of Expandable Metal Sheets

Modern expandable metal

sheets demonstrate exceptional technical specifications:

- Load capacity: Up to 890 psi compressive strength in stainless steel variants

- Thermal resistance: Stable performance between -40°F to 1,200°F

- Corrosion resistance: 5,000+ hours in salt spray tests (ASTM B117)

The diamond-shaped mesh pattern, available in strand widths from 0.25" to 4", provides 18-76% open area ratios. This architectural flexibility enables applications ranging from ballistic shielding to HVAC filtration systems.

Performance Comparison: Leading Manufacturers

| Vendor |

Material Grade |

Thickness Range |

Max Width |

Lead Time |

| MetalEx Corp |

AISI 304/316 |

0.5-6mm |

2.4m |

5 days |

| SteelMesh Inc |

Carbon Steel |

1-12mm |

3.0m |

10 days |

| AlloyTec |

Aluminum 6061 |

0.8-4mm |

1.8m |

7 days |

Customization Options for Industrial Needs

Advanced manufacturers now offer:

- Laser-cut profiles with ±0.1mm precision

- Hybrid material layering (steel + polymer composites)

- Surface treatments: Powder coating, galvanization, PVDF

Custom expandable steel solutions reduce material waste by 22-35% compared to traditional fabrication methods, according to 2023 industry benchmarks.

Real-World Applications Across Industries

Case Study Highlights:

Automotive: Tesla's Cybertruck utilizes expandable aluminum sheets for impact-absorbing door panels, reducing component weight by 41%.

Construction: The Burj Al Arab facade incorporates 8,500m² of corrosion-resistant steel mesh, withstanding 75mph desert winds.

Cost Efficiency and Sustainability Metrics

Lifecycle analysis reveals:

- 35% lower installation costs vs. solid metal alternatives

- 78% recyclability rate for steel variants

- 17% energy reduction in climate control systems using airflow-optimized panels

Future Trends in Expandable Steel Innovation

Emerging technologies like AI-driven pattern optimization and nano-coated steel meshes promise 15-20% performance improvements. The integration of smart sensors into expandable metal sheets (patent pending: US2024178921A1) will enable real-time structural health monitoring, revolutionizing maintenance paradigms.

(expandable metal)

FAQS on expandable metal

Q: What is expandable metal used for?

A: Expandable metal is commonly used for industrial grating, architectural cladding, and safety barriers. Its lightweight yet durable structure allows airflow and visibility while providing strength. It’s ideal for applications requiring ventilation and security.

Q: How is an expandable metal sheet manufactured?

A: Expandable metal sheets are made by cutting and stretching a single metal plate, creating a mesh-like pattern. This process retains material strength while reducing weight. Common materials include steel, aluminum, and stainless steel.

Q: What are the advantages of expandable steel over solid steel?

A: Expandable steel offers better airflow, reduced weight, and cost-efficiency compared to solid steel. It maintains structural integrity while allowing light and ventilation. It’s often used in construction and machinery guards.

Q: Can expandable metal sheets be customized for specific projects?

A: Yes, expandable metal sheets can be tailored in thickness, strand width, and pattern size. Customization ensures suitability for unique architectural, industrial, or decorative needs. Coatings can also be added for corrosion resistance.

Q: Is expandable steel suitable for outdoor applications?

A: Yes, expandable steel is durable and often coated or galvanized to resist weathering and corrosion. It’s widely used in outdoor fencing, façades, and drainage systems. Regular maintenance can further extend its lifespan.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)