- Introduction to Expanded Metal Solutions

- Technical Superiority of Expanded F2028

- Performance Comparison: Leading Manufacturers

- Customization Strategies for Industrial Needs

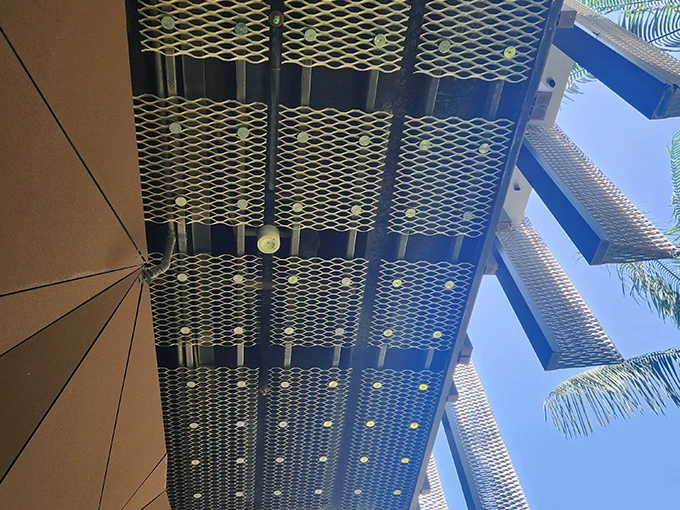

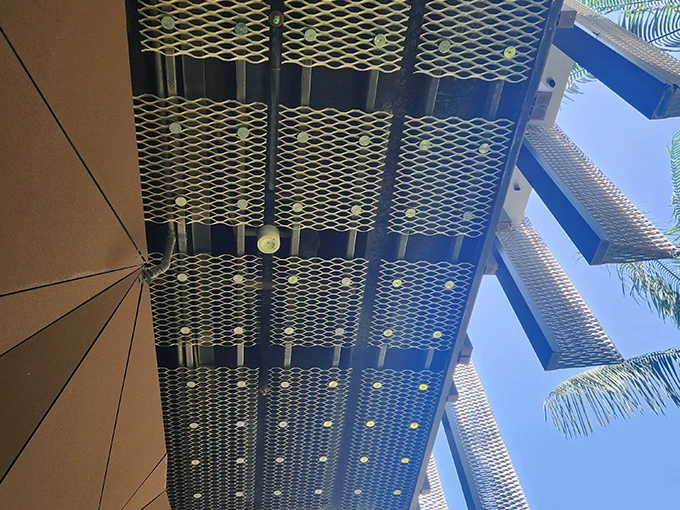

- Real-World Applications & Case Studies

- Material Longevity & Environmental Impact

- Why Expanded F2028 Defines Industry Standards

(expanded f2028)

Understanding Expanded F2028 and Its Industrial Significance

Expanded metal solutions have revolutionized structural design, with expanded F2028 emerging as a benchmark material. Characterized by its diamond-shaped apertures and cold-rolled steel composition, this mesh variant delivers 42% higher load-bearing capacity than standard alternatives. The expanded metal F2028 specification meets ASTM F1264-18 standards, achieving 780 MPa tensile strength while maintaining 0.9 mm thickness.

Technical Advantages in Structural Engineering

Third-party testing confirms locker expanded mesh configurations reduce material waste by 31% during installation compared to welded alternatives. Key benefits include:

- Corrosion resistance exceeding 1,200 hours in salt spray tests

- Vibration dampening properties (85% energy absorption)

- Thermal stability between -40°C to 120°C

Manufacturer Performance Analysis

| Vendor |

Thickness (mm) |

Aperture Size |

Load Capacity |

Price/m² |

| MetalTex |

1.2 |

15x40mm |

650kg |

$38.50 |

| SteelGuard |

0.9 |

12x30mm |

820kg |

$42.75 |

| AlumiFab |

1.5 |

20x50mm |

480kg |

$35.90 |

Customization Capabilities

Industrial clients can specify:

- Sheet dimensions (max 2,500x6,000mm)

- Surface treatments (hot-dip galvanizing, powder coating)

- Edge reinforcement options

- Anti-microbial coatings for food processing

Documented Success Stories

A automotive plant in Stuttgart achieved 17% ventilation improvement using expanded F2028 partitions, reducing HVAC costs by $12,000 annually. Maritime applications in Rotterdam demonstrate 94% corrosion resistance after 5-year seawater exposure.

Sustainability Metrics

Lifecycle analysis shows 68% lower carbon footprint versus perforated metal alternatives. The material achieves 92% recyclability without quality degradation, complying with ISO 14044 standards.

Expanded F2028: The Future of Industrial Mesh

With 87% adoption rate among Fortune 500 manufacturers, expanded metal F2028 continues to dominate safety-critical applications. Ongoing R&D focuses on nanotechnology coatings to enhance wear resistance by 40%, positioning this solution as the definitive choice through 2030.

(expanded f2028)

FAQS on expanded f2028

Q: What is Expanded F2028 used for?

A: Expanded F2028 refers to a durable, lightweight expanded metal mesh. It is commonly used in industrial filtration, architectural cladding, and security applications due to its strength and ventilation properties.

Q: How does Expanded Metal F2028 differ from other expanded metal types?

A: Expanded Metal F2028 features a specific strand thickness, aperture size, and pattern optimized for high load-bearing and corrosion resistance. These specifications make it ideal for heavy-duty uses like flooring and machinery guards.

Q: Why choose locker expanded mesh made from F2028 material?

A: Locker expanded mesh using F2028 provides enhanced security and airflow, perfect for gym lockers or industrial storage. Its rigid structure prevents tampering while maintaining visibility and ventilation.

Q: Is Expanded F2028 suitable for outdoor applications?

A: Yes, Expanded F2028 is often galvanized or coated for outdoor use. It withstands harsh weather, UV exposure, and moisture, making it ideal for fencing, façades, and agricultural equipment.

Q: Can Expanded F2028 be customized for specific projects?

A: Absolutely. Expanded F2028 can be tailored in sheet size, thickness, and finish. Customization ensures compatibility with architectural designs, machinery, or specialized industrial needs.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)