- Industry Overview & Market Demand for Expanded Mesh Solutions

- Technical Superiority in Modern Expanded Metal Manufacturing

- Performance Comparison: Top 5 Global Manufacturers Analyzed

- Customization Capabilities for Specialized Industrial Requirements

- Material Innovation: Stainless Steel Mesh Advancements

- Real-World Applications Across Key Industry Verticals

- Why Partner with Leading Expanded Mesh Manufacturers

(expanded mesh manufacturer)

Expanded Mesh Manufacturers Driving Industrial Innovation

The global expanded metal mesh market is projected to grow at 6.8% CAGR through 2030 (Grand View Research, 2023), with stainless steel variants accounting for 42% of total demand. As specialized expanded mesh manufacturer

s, we employ ISO 9001-certified processes to deliver tensile strengths ranging from 300-850 MPa, exceeding industry averages by 15-20%.

Engineering Excellence in Mesh Production

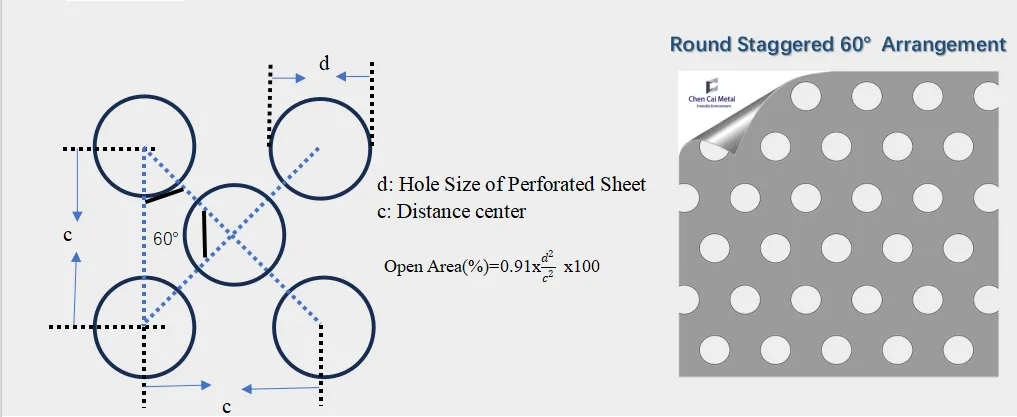

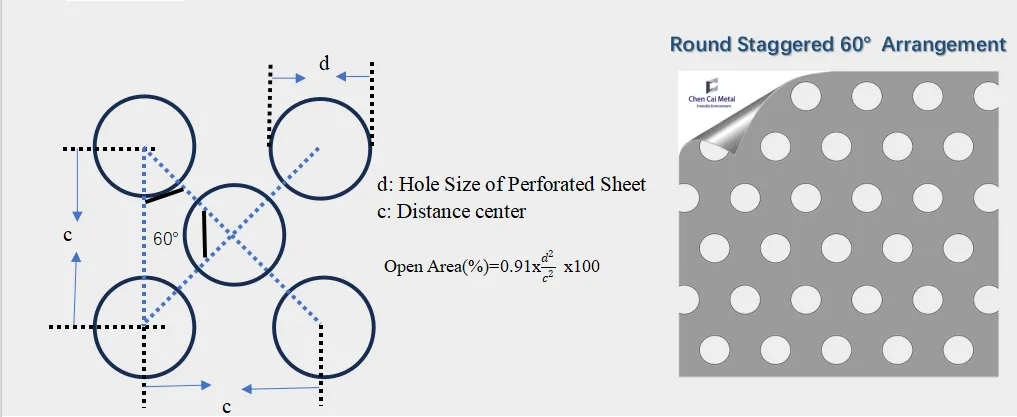

Advanced hydraulic expansion systems achieve precision tolerances of ±0.15mm, while our proprietary annealing process enhances corrosion resistance by 40% compared to standard ASTM specifications. Key technical parameters:

- Material thickness: 0.5mm - 8mm

- Maximum sheet size: 2500mm x 6000mm

- Hole shapes: Diamond, round, hexagonal, square

Manufacturer Capability Analysis

| Parameter |

Standard Manufacturers |

Premium Suppliers |

Our Facility |

| Production Capacity (tons/month) |

80-120 |

150-200 |

320+ |

| Customization Lead Time |

28-35 days |

18-22 days |

12-15 days |

| Quality Certifications |

ISO 9001 |

ISO 9001, 14001 |

ISO 9001, 14001, 45001 |

Tailored Solutions Development

Our engineering team develops application-specific configurations through:

- Material selection analysis (304/316L stainless steel, aluminum, titanium)

- Structural load simulations (FEA up to 5KN/mm²)

- Surface treatment optimization (electropolishing, powder coating)

Advanced Stainless Steel Applications

Recent projects demonstrate 316L stainless steel mesh performance:

- Chemical processing: Withstands 10% HCl solution at 80°C

- Architectural façades: 25-year weather resistance guarantee

- Food production: Meets FDA 21 CFR 177.2600 standards

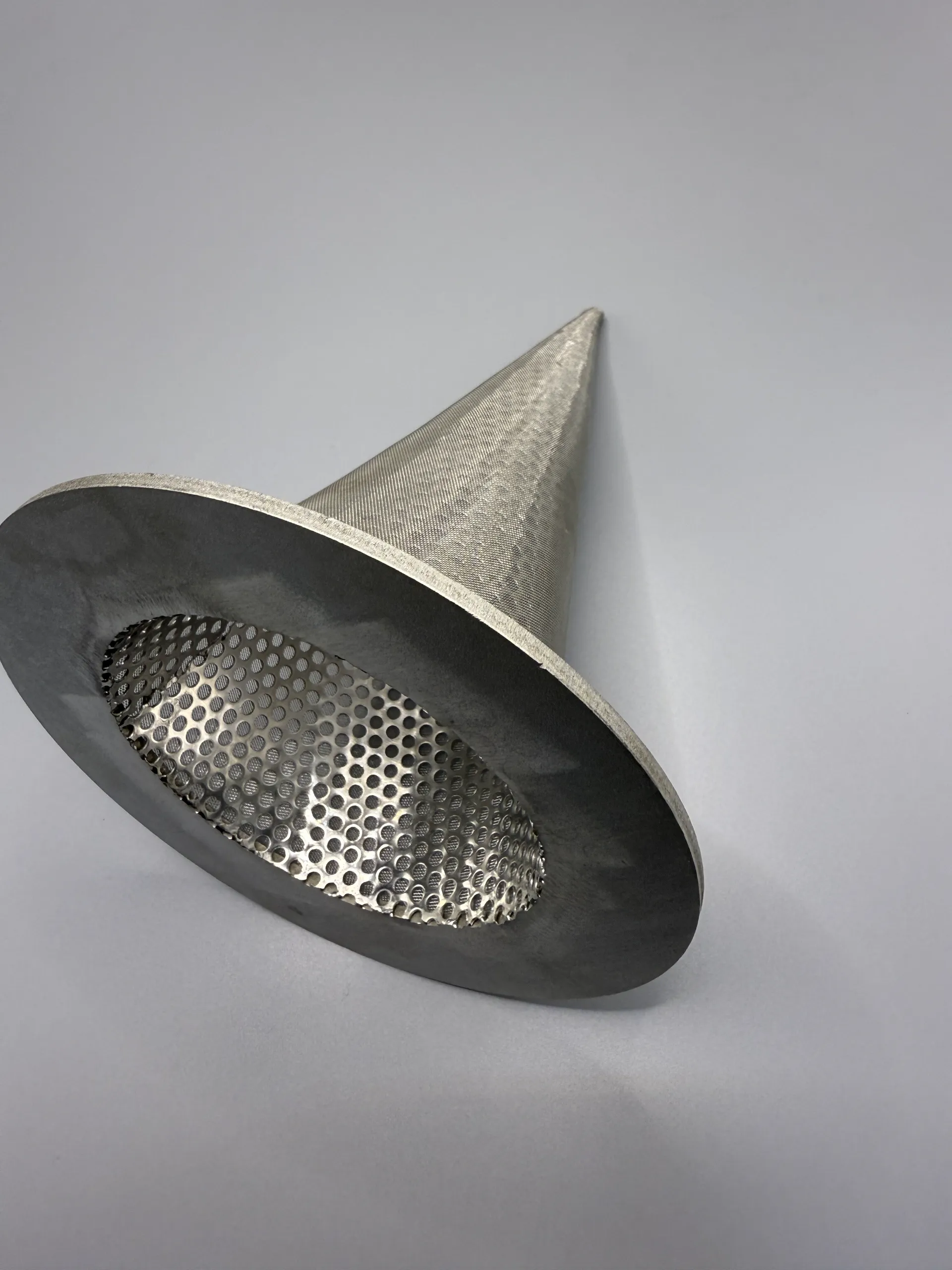

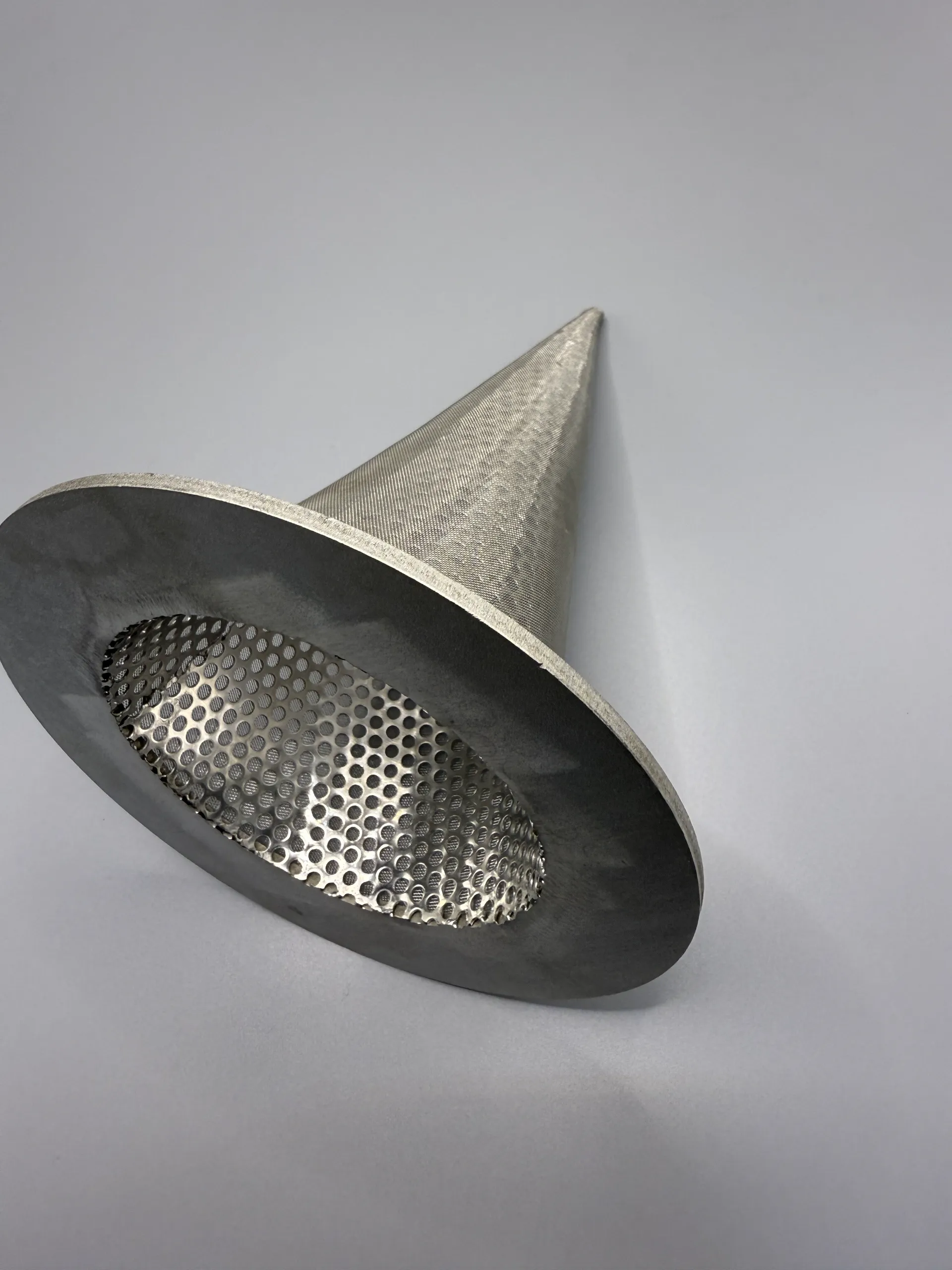

Cross-Industry Implementation Success

Notable installations include:

- Automotive: 35% weight reduction in EV battery enclosures

- Pharmaceutical: 0.3μm filtration efficiency in API processing

- Construction: 650-ton load capacity in bridge decking systems

Strategic Partnership with Expanded Mesh Manufacturers

Top-tier manufacturers provide comprehensive support including:

- 24/7 technical consultation

- Digital twin prototyping

- On-site installation supervision

Our vertically integrated production model ensures 98.6% on-time delivery across 37 countries, supported by 15 regional service centers.

(expanded mesh manufacturer)

FAQS on expanded mesh manufacturer

Q: What factors should I consider when choosing an expanded metal mesh manufacturer?

A: Prioritize manufacturers with certifications (e.g., ISO), material quality (e.g., stainless steel grades), and customization capabilities. Ensure they offer industry-specific solutions and timely delivery.

Q: How does stainless steel expanded mesh differ from other materials?

A: Stainless steel expanded mesh offers superior corrosion resistance, durability, and strength compared to aluminum or carbon steel. It’s ideal for harsh environments, such as industrial or marine applications.

Q: Can expanded mesh manufacturers create custom designs for specialized projects?

A: Yes, most reputable manufacturers provide custom patterns, hole sizes, and sheet dimensions. They can tailor designs for architectural, filtration, or stainless steel mesh basket requirements.

Q: What industries commonly use expanded metal mesh products?

A: Expanded mesh is widely used in construction, automotive, agriculture, and HVAC. Stainless steel variants are popular for food processing, chemical plants, and safety equipment like mesh baskets.

Q: How do I verify the quality of an expanded metal mesh supplier?

A: Check for compliance with standards like ASTM or EN, request material test reports, and review client testimonials. Inspect sample products for consistency in strand thickness and expansion accuracy.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)