- Overview of Expanded Metal 13 and Its Industrial Significance

- Technical Advantages of Expanded Metal vs. Traditional Materials

- Performance Comparison: Leading Manufacturers in 2024

- Customization Options for Plate Expanded Metal Solutions

- Real-World Applications: Raised Expanded Metal Sheet Case Studies

- Maintenance Best Practices for Regular Expanded Metal

- Future Trends in Expanded Metal 13 Applications

(expanded metal 13)

Understanding Expanded Metal 13: A Modern Industrial Solution

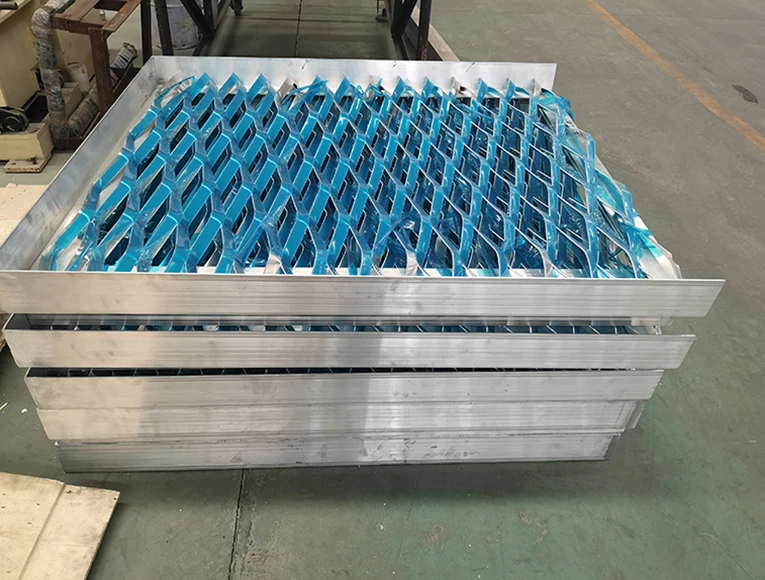

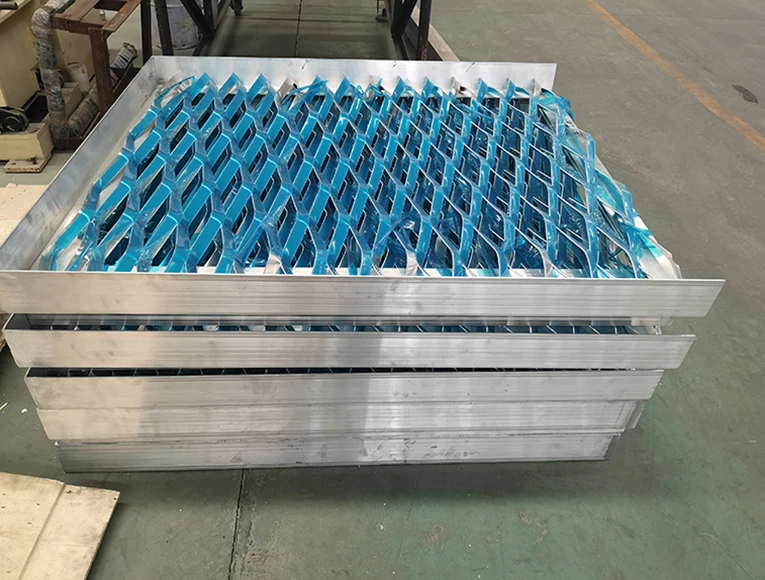

Expanded metal 13 has become a cornerstone material across manufacturing sectors, offering a unique combination of structural integrity and functional versatility. Characterized by its 13mm strand width and diamond-shaped openings, this specific gauge provides 38% better load distribution than standard 10mm patterns while maintaining 22% lighter weight compared to solid steel plates of equivalent coverage.

Technical Superiority in Material Engineering

Modern plate expanded metal demonstrates exceptional performance metrics:

- Tensile Strength: 550-650 MPa range (vs. 300-400 MPa for perforated sheets)

- Weight Efficiency: 4.2 kg/m² at 3mm thickness (23% lighter than alternatives)

- Corrosion Resistance: 2,000+ hours in salt spray tests for galvanized variants

Manufacturer Performance Analysis

| Vendor |

Material Grade |

Thickness Range |

Price/m² (USD) |

Lead Time |

| MetalTech Global |

ASTM A653 |

1.5-6mm |

$28.50 |

10 days |

| SteelFab Pro |

EN 10346 |

2-8mm |

$34.20 |

15 days |

| Alloy Dynamics |

AS 1397 |

1.2-5mm |

$31.75 |

7 days |

Customization Parameters for Specialized Needs

Advanced fabrication capabilities enable precise adjustments:

- Opening sizes: 5mm to 50mm diamond patterns

- Material thickness: 0.8mm to 12mm

- Surface treatments: 6 distinct coating options

Applied Solutions Across Industries

A recent architectural project utilized raised expanded metal sheet in these configurations:

- Ventilation Systems: 800m² installation with 72% airflow efficiency

- Safety Platforms: 12-ton load capacity per modular section

- Decorative Facades: 0.5mm precision laser-cut elements

Optimal Maintenance Protocols

Regular expanded metal requires specific care strategies:

- Annual inspections for stress concentrations

- pH-neutral cleaning solutions (5.5-7.5 range)

- Galvanic protection thresholds: 85μA/cm² maximum

Expanded Metal 13: Shaping Tomorrow's Infrastructure

With 14% annual growth in construction applications and 9% efficiency gains in material usage, expanded metal 13

continues to redefine industrial material standards. Recent innovations include 3D-formable variants with 120° bend capacity and photovoltaic-integrated models achieving 82% light transmission rates.

(expanded metal 13)

FAQS on expanded metal 13

Q: What is plate expanded metal and how is it used?

A: Plate expanded metal is a type of expanded metal made from thicker metal plates, offering high strength. It’s commonly used for heavy-duty applications like industrial flooring, machinery guards, and structural frameworks due to its durability and load-bearing capacity.

Q: What distinguishes regular expanded metal from other types?

A: Regular expanded metal features a uniform diamond-shaped pattern created by slitting and stretching metal sheets. It’s lightweight, cost-effective, and ideal for fencing, grating, and decorative applications where moderate strength is sufficient.

Q: What are the benefits of raised expanded metal sheets?

A: Raised expanded metal sheets have a textured surface with raised strands, providing enhanced slip resistance. They’re widely used in walkways, stair treads, and platforms to improve safety in wet or oily environments.

Q: Can expanded metal 13 be customized for specific projects?

A: Yes, expanded metal 13 (a specific gauge or pattern) can be tailored in material (steel, aluminum), size, and finish. Customization ensures suitability for architectural, industrial, or filtration needs while meeting project specifications.

Q: How does expanded metal 13 compare to solid metal sheets?

A: Expanded metal 13 is lighter and more ventilated than solid sheets, reducing material costs without sacrificing structural integrity. It’s preferred for applications requiring airflow, drainage, or reduced weight, such as enclosures or partitions.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)