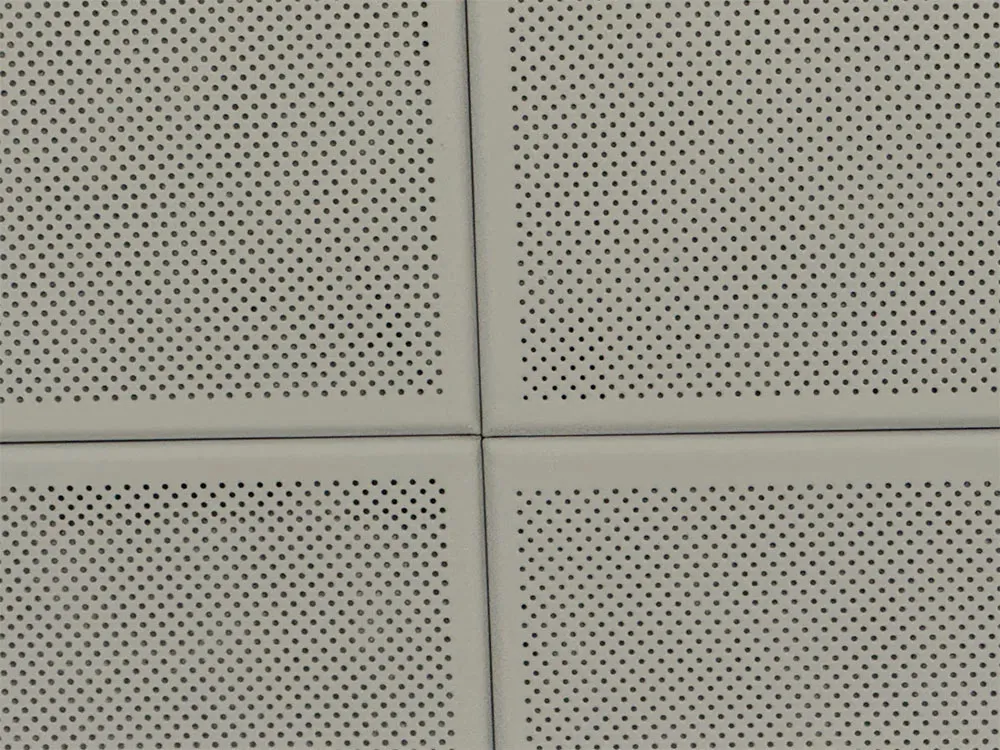

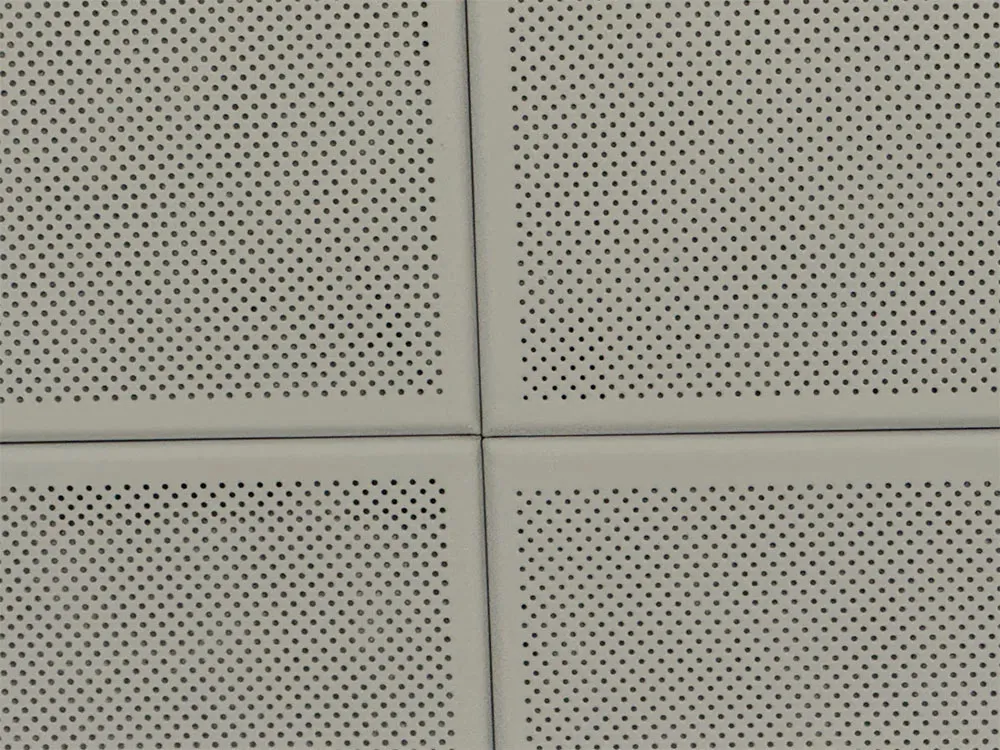

- Overview of Expanded Metal 24x24 Applications

- Material Specifications & Technical Advantages

- Performance Comparison: Leading Supplier Metrics

- Custom Fabrication Processes

- Industry-Specific Use Cases

- Installation Best Practices

- Future Trends in Expanded Metal 24x24 Utilization

(expanded metal 24x24)

Understanding Expanded Metal 24x24 for Industrial Applications

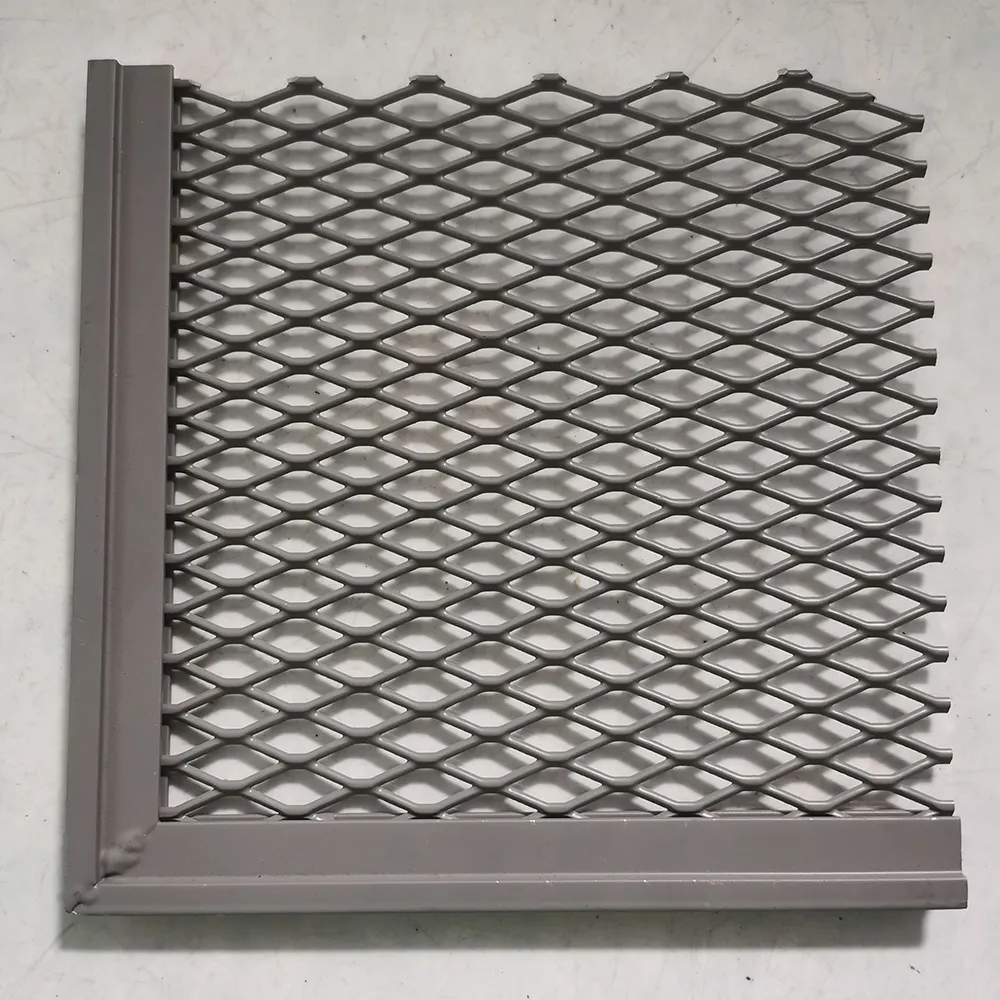

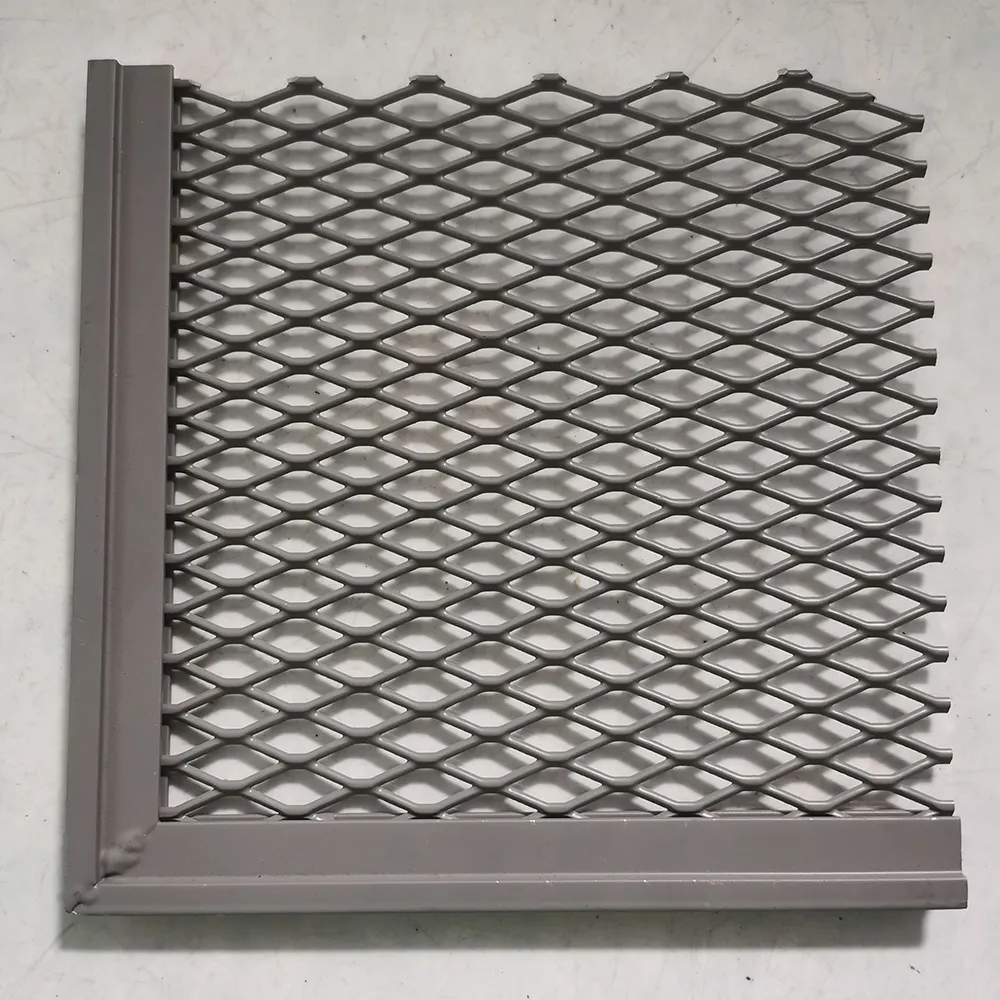

Expanded metal 24x24 refers to a standardized pattern with 24 strands per foot in both directions, creating 0.25" diamond-shaped openings. This configuration delivers 76% open area, making it ideal for filtration systems requiring high flow rates. Unlike conventional wire mesh, the expanded metal manufacturing process produces a single-piece material with 40% less weight than solid steel plates of equivalent strength.

Material Specifications & Structural Benefits

Manufactured from cold-rolled steel (CRS) or aluminum 6061-T6, expanded metal 24x24

exhibits:

- Tensile strength: 65,000 psi (CRS) / 45,000 psi (Aluminum)

- Thickness range: 0.036" to 0.125"

- Load capacity: 250 lbs/ft² (standard) to 800 lbs/ft² (reinforced)

The expanded pattern increases surface rigidity by 30% compared to flat sheets while maintaining weldability through 18% material stretch during expansion.

Supplier Comparison: Technical Specifications

| Vendor |

Material Grade |

Thickness Tolerance |

Lead Time |

MOQ |

| MetalTech |

AISI 304 |

±0.002" |

5 days |

50 sheets |

| SteelFab Co. |

ASTM A653 |

±0.005" |

10 days |

100 sheets |

| AlumCore |

AA 6061 |

±0.003" |

7 days |

75 sheets |

Custom Fabrication Techniques

Advanced manufacturers now offer laser-cut edges with ±0.004" precision for architectural applications. Roll-forming capabilities enable curvature radii down to 12" without material cracking. Powder coating adhesion reaches 4,500 psi on expanded surfaces through electrostatic deposition methods.

Practical Implementation Scenarios

A recent warehouse ventilation project utilized 1,200m² of expanded metal 24x24, achieving 85 CFM airflow with 7% static pressure reduction versus traditional grilles. In automotive manufacturing, the material withstands 900°F spray booth temperatures without warping.

Installation Methodology

Proper edge clamping (18-22 ft-lb torque) prevents vibration-induced fatigue. For outdoor applications, galvanic compatibility analysis reduces corrosion rates by 60% when pairing aluminum expanded metal with stainless steel fasteners.

Expanded Metal 24x24 in Next-Gen Manufacturing

Recent advancements include nano-coated versions reducing particulate adhesion by 92% in pharmaceutical cleanrooms. The global market for precision expanded metal reached $2.4B in 2023, with 24x24 pattern demand growing at 6.8% CAGR due to its balance of structural efficiency and material economy.

(expanded metal 24x24)

FAQS on expanded metal 24x24

Q: What does the specification "24x24" mean in expanded metal 24x24?

A: The "24x24" refers to the strand count per inch, indicating 24 strands in both the length and width directions. This configuration balances strength and airflow, making it ideal for ventilation and filtration applications.

Q: How does regular expanded metal differ from expanded metal 24x24?

A: Regular expanded metal has a broader range of strand/bond sizes, while 24x24 specifies uniform 24 strands per inch. The latter offers consistent openings for precision uses like screens or partitions.

Q: What are the benefits of rolled expanded metal?

A: Rolled expanded metal undergoes flattening for a smooth surface and reduced thickness. It’s preferred for architectural or safety applications requiring even surfaces and sharp-edge elimination.

Q: Can expanded metal 24x24 be used for heavy-duty applications?

A: Yes, when made from thicker gauge metals like steel or stainless steel. Its dense pattern provides structural support for walkways, machine guards, or industrial flooring.

Q: Which industries commonly use expanded metal 24x24?

A: HVAC, construction, and automotive industries utilize it for grilles, filters, and protective barriers. Its versatility also suits decorative projects requiring precise geometric patterns.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)