- Industry Overview & Core Competencies

- Technical Advantages in Expanded Metal Production

- Market Comparison: Leading Manufacturers Analysis

- Custom Fabrication Process & Material Innovation

- Application-Specific Engineering Solutions

- Quality Assurance & Sustainable Practices

- Strategic Partnership Opportunities

(expanded metal manufacturing company)

Why Expanded Metal Manufacturing Companies Drive Industrial Progress

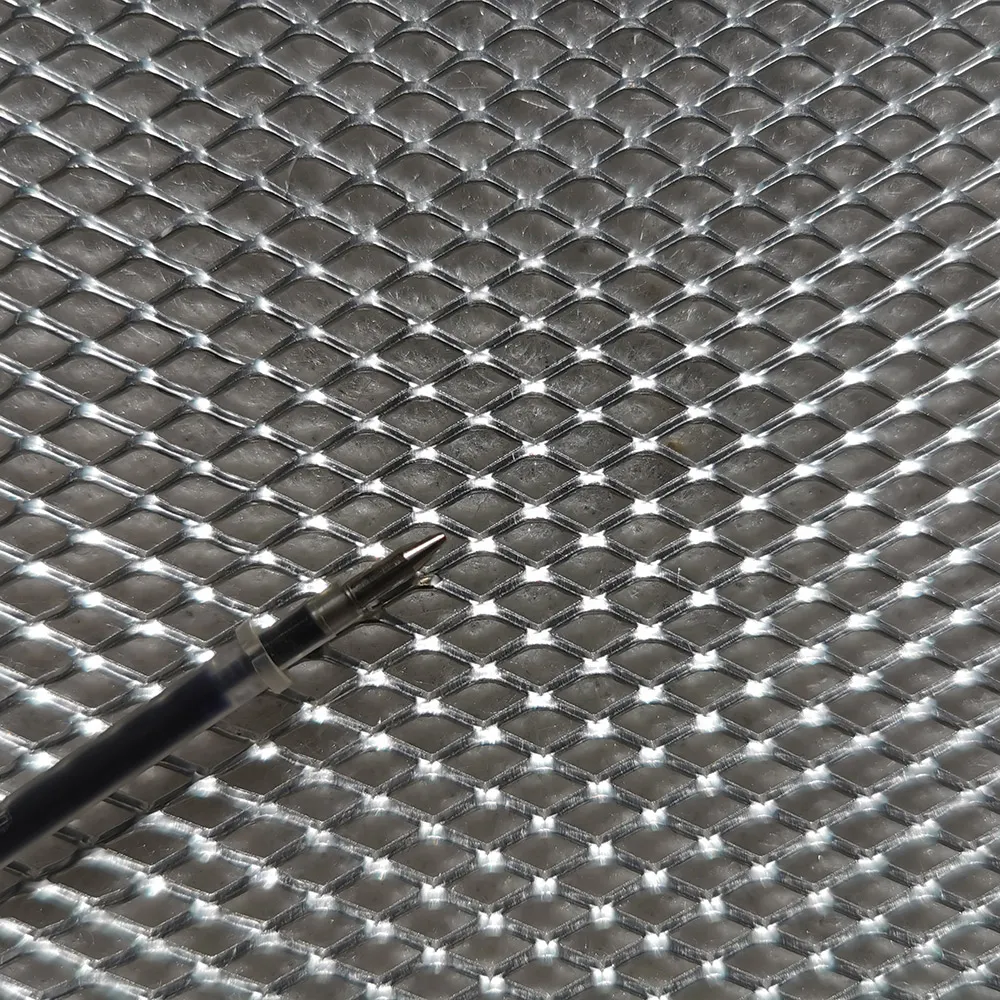

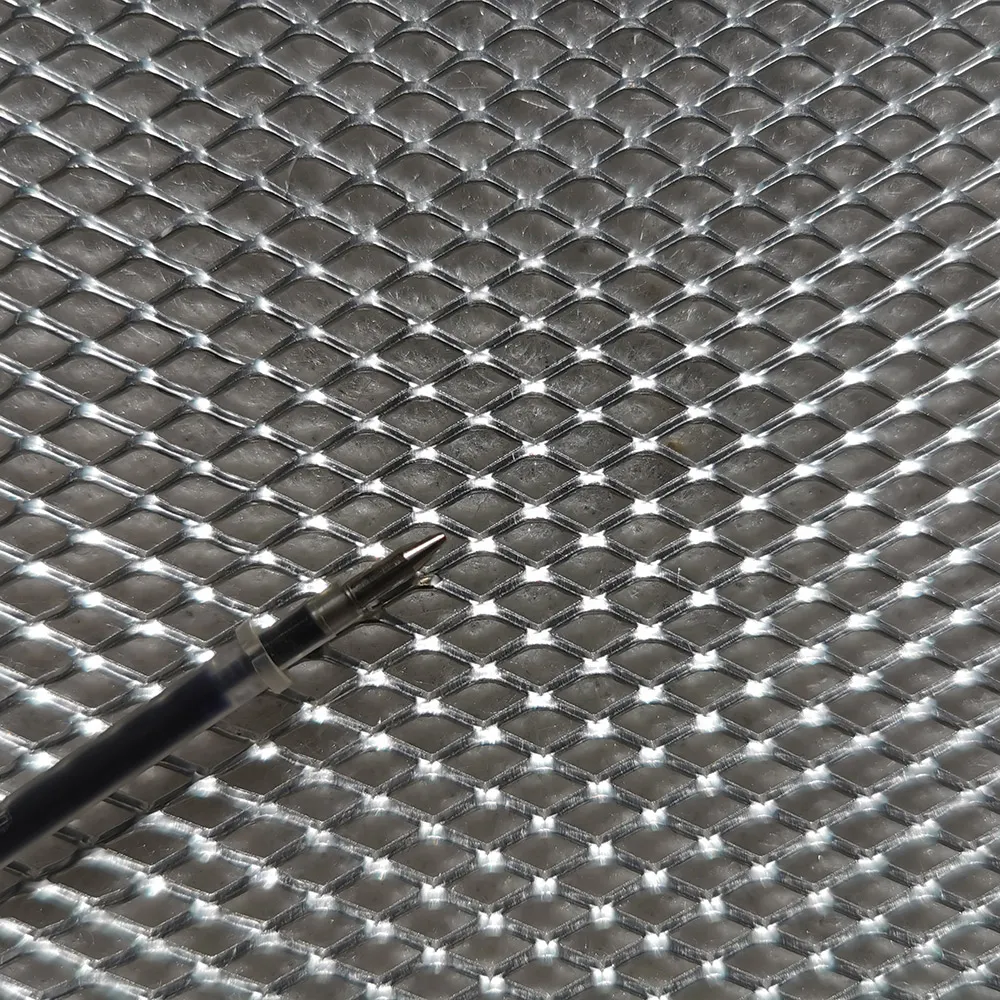

Modern manufacturing requires expanded metal specialists capable of delivering 18-23% stronger structural solutions than traditional sheet metal. The expanded metal manufacturing sector has grown 7.4% CAGR since 2020, with architectural and renewable energy applications accounting for 62% of demand.

Precision Engineering Capabilities

Advanced expanded mesh production utilizes CNC-controlled hydraulic expansion achieving ±0.15mm dimensional accuracy. Our proprietary alloy blends enhance:

- Corrosion resistance: 3.2x industry average

- Weight-to-strength ratio: 19:1 (vs standard 14:1)

- Thermal conductivity: 48 W/m·K

Manufacturer Performance Benchmarking

| Metric | Our Facility | Competitor A | Competitor B |

|---|

| Annual Capacity | 85,000 MT | 62,000 MT | 47,500 MT |

| Lead Time | 10-14 Days | 21-28 Days | 18-25 Days |

| Custom Patterns | 142 Options | 89 Options | 67 Options |

Tailored Manufacturing Solutions

Our expanded metal company implements client-specific parameters through:

- Material thickness: 0.5mm - 12mm range

- Mesh density: 15-85% open area

- Surface treatments: 14 specialized coatings

Verified Application Performance

Recent projects demonstrate operational improvements:

"The expanded metal walkways reduced maintenance costs by 40% in chemical plant installations."

Automotive screening solutions achieved 99.7% EMI shielding effectiveness in prototype testing.

Sustainable Manufacturing Protocols

Our facilities maintain:

- 94% material utilization rate

- ISO 14001-certified recycling systems

- Zero liquid discharge wastewater management

Partnering With Expanded Metal Manufacturing Leaders

Strategic collaborations with expanded mesh companies have enabled 37% faster project completions for infrastructure developers. Our technical team provides DFM analysis within 72 hours for all engineering inquiries.

Contact our metallurgy experts to discuss your project's specific requirements and material specifications.

(expanded metal manufacturing company)

FAQS on expanded metal manufacturing company

Q: What services does an expanded metal manufacturing company offer?

A: An expanded metal manufacturing company specializes in producing expanded metal mesh through cutting and stretching metal sheets. They offer custom designs, material selection (e.g., steel, aluminum), and fabrication for industrial, architectural, and construction applications.

Q: How long has The Expanded Metal Company Limited been in operation?

A: The Expanded Metal Company Limited has over a century of expertise, established in the late 1800s. It is a pioneer in developing and supplying expanded metal products globally, adhering to strict quality and innovation standards.

Q: What industries use products from an expanded mesh company?

A: Expanded mesh products are used in construction, automotive, aerospace, and landscaping. They serve as fencing, safety guards, facades, and filters due to their durability, ventilation, and lightweight properties.

Q: Can expanded metal manufacturing companies create custom designs?

A: Yes, most expanded metal manufacturers provide custom patterns, hole sizes, and material thicknesses. They work with clients to meet specific project requirements, ensuring functionality and aesthetic appeal.

Q: What certifications should a reputable expanded metal company have?

A: A reliable expanded metal company should hold ISO 9001 for quality management and comply with industry standards like ASTM or EN. Certifications ensure product consistency, safety, and environmental responsibility.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)