11111

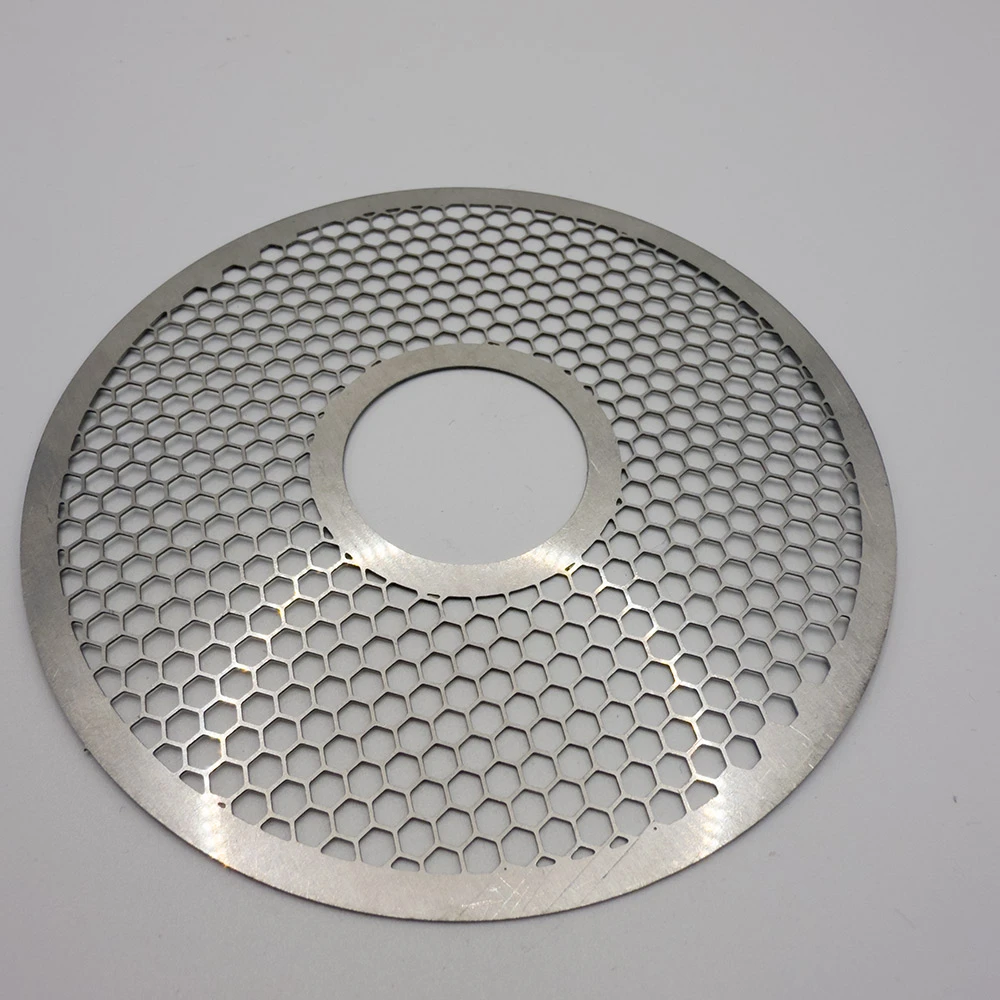

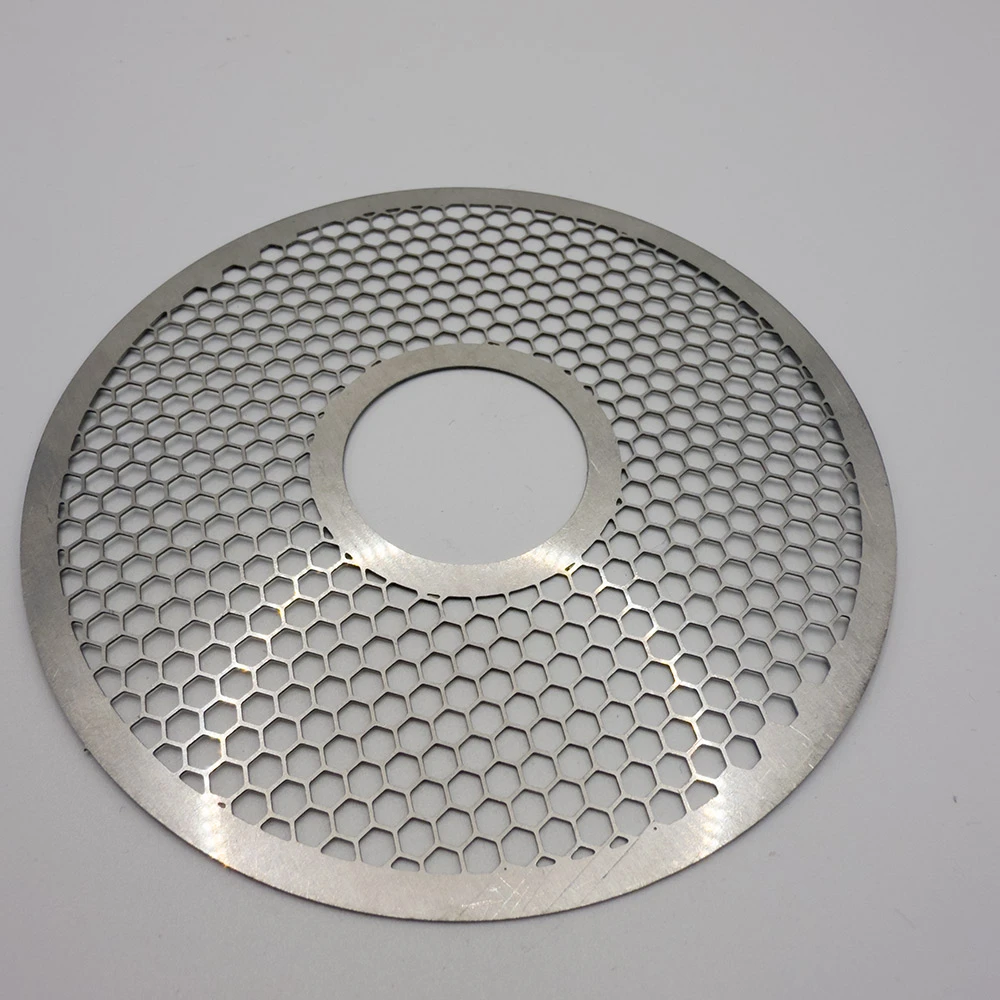

Filter Disc / Cap: Advanced Sealing Solutions for Industrial Applications

At Anping Chen Cai Metal Manufacture Co., Ltd., we specialize in providing high-performance sealing solutions designed to meet the demanding requirements of industrial applications. Our Filter Disc / Cap is engineered to deliver exceptional durability, precision, and reliability in critical environments. Whether you're in the food processing, chemical, or pharmaceutical industries, our products are tailored to ensure optimal performance and compliance with industry standards.

Product Overview: Precision Engineering for Industrial Sealing

The Filter Disc / Cap is a critical component in various industrial systems, designed to provide a secure and leak-proof seal while allowing for efficient filtration. Crafted from premium-grade materials, these components are engineered to withstand harsh environments, ensuring long-term performance and minimal maintenance. Our product line includes screen gaskets, screen rubber gasket, sanitary gasket screen, and hose gasket with screen, each tailored to specific application needs.

Key Features and Technical Specifications

- Material Composition: High-quality stainless steel, rubber, or specialized alloys, chosen based on application requirements.

- Dimensions: Available in a range of sizes to accommodate diverse equipment configurations.

- Pressure Resistance: Designed to handle high-pressure environments without compromising integrity.

- Corrosion Resistance: Coated or treated to resist chemical exposure and environmental degradation.

- Customization: Tailored to meet specific industry standards or customer specifications.

Market Demand and Industry Challenges

Industrial sealing solutions are in high demand due to the increasing need for efficient and reliable systems in sectors like food processing, pharmaceuticals, and chemical manufacturing. However, traditional sealing methods often face challenges such as:

- Leakage risks in high-pressure or high-temperature environments.

- Short lifespan due to material degradation.

- High maintenance costs and downtime.

Our Filter Disc / Cap addresses these issues through advanced design and material selection. By integrating robust sealing mechanisms with precision engineering, we ensure that our products outperform conventional alternatives, reducing operational costs and enhancing system efficiency.

Company Expertise: A Leader in Industrial Sealing Solutions

Anping Chen Cai Metal Manufacture Co., Ltd. has established itself as a trusted name in the industrial manufacturing sector. With over 10 years of experience, we have developed a reputation for delivering high-quality products that meet stringent industry standards. Our commitment to innovation and customer satisfaction has enabled us to serve a global clientele, including major players in the food, chemical, and pharmaceutical industries.

Our company website showcases our extensive product range, technical specifications, and customer testimonials, highlighting our dedication to excellence and reliability.

Research and Development Capabilities

At Anping Chen Cai, we invest heavily in research and development to stay at the forefront of industrial sealing technology. Our team of engineers and technicians continuously explores new materials and manufacturing techniques to enhance product performance. This focus on innovation ensures that our Filter Disc / Cap remains a cutting-edge solution for modern industrial challenges.

Applications and Industry Impact

The versatility of our Filter Disc / Cap makes it an essential component in various industries:

1. Food and Beverage Industry

In food processing, hygiene and safety are paramount. Our sanitary gasket screen ensures contamination-free operations, meeting strict FDA and ISO standards. The product's corrosion-resistant design prevents bacterial growth, making it ideal for use in tanks, pipelines, and processing equipment.

2. Chemical and Pharmaceutical Industries

For chemical and pharmaceutical applications, the screen rubber gasket provides a reliable seal against corrosive substances. Its high-pressure resistance and durability ensure that critical systems remain leak-proof, even under extreme conditions.

3. Manufacturing and Automotive Sectors

Our hose gasket with screen is widely used in manufacturing and automotive applications to prevent fluid leaks and maintain system integrity. The product's adaptability to different pressure levels makes it a preferred choice for diverse machinery and equipment.

Product Performance and Customer Feedback

Customers consistently praise our Filter Disc / Cap for its exceptional performance and durability. One satisfied client from the food processing industry stated, "The sanitary gasket screen has significantly reduced maintenance costs and improved our production efficiency. We rely on Anping Chen Cai for all our sealing needs."

Another user in the chemical sector noted, "The screen rubber gasket has proven to be more resilient than other products we've used. Its ability to withstand harsh chemicals and high pressure is unmatched."

Implementation and Customization Options

We understand that every industrial application has unique requirements. That's why we offer tailored solutions to meet your specific needs:

- Custom Design: Our engineers work closely with clients to develop bespoke sealing solutions for specialized equipment.

- Material Selection: Choose from a range of materials, including stainless steel, rubber, or alloys, to suit your operational environment.

- Size and Configuration: Available in various sizes and configurations to ensure compatibility with your machinery.

For more details on customization options, visit our company page.

Safety, Compliance, and Environmental Responsibility

Safety and environmental compliance are at the core of our manufacturing process. All our Filter Disc / Cap products adhere to international standards, including ISO 9001 and FDA regulations. We prioritize the use of eco-friendly materials and sustainable production practices to minimize our environmental footprint while ensuring the highest quality standards.

Packaging and Logistics

Our products are packaged to ensure safe transportation and storage. Each screen gasket is securely sealed in protective materials to prevent damage during transit. For bulk orders, we offer customized packaging solutions to optimize space and reduce shipping costs. Our logistics team ensures timely delivery, with tracking information provided for every shipment.

Customer Support and After-Sales Services

We are committed to providing exceptional customer support throughout the product lifecycle. Our team of experts is available to assist with:

- Technical Consultation: Guidance on product selection, installation, and maintenance.

- Warranty and Repairs: Comprehensive warranty coverage and prompt repair services.

- Custom Solutions: Collaborative development of tailored sealing systems for complex applications.

Contact us today to learn more about our Filter Disc / Cap and how we can meet your industrial sealing needs.

Conclusion

Invest in reliable, high-performance sealing solutions with Anping Chen Cai Metal Manufacture Co., Ltd. Our Filter Disc / Cap is designed to enhance operational efficiency, reduce downtime, and ensure compliance with industry standards. Discover the difference of precision engineering and superior quality today.

Frequently Asked Questions (FAQ)

1. What materials are used in the Filter Disc / Cap?

The Filter Disc / Cap is manufactured using high-grade stainless steel, rubber, or specialized alloys, depending on the application requirements. These materials are selected for their durability, corrosion resistance, and ability to withstand harsh environments.

2. Can the Filter Disc / Cap be customized?

Yes, we offer customized solutions to meet specific industry standards or customer requirements. Our team of engineers works closely with clients to design and manufacture sealing components tailored to their unique needs.

3. What industries use the Filter Disc / Cap?

Our product is widely used in the food and beverage, chemical, pharmaceutical, and manufacturing industries. It is ideal for applications requiring secure sealing and efficient filtration, such as tanks, pipelines, and processing equipment.

4. How long does it take to receive an order?

Delivery times vary depending on the order size and shipping location. We ensure timely delivery with tracking information provided for every shipment. For bulk orders, we offer customized logistics solutions to optimize efficiency.

5. What after-sales support is available?

We provide comprehensive after-sales support, including technical consultation, warranty services, and repair assistance. Our team is dedicated to ensuring customer satisfaction and long-term product performance.

For more information or to place an order, visit our company page or contact us directly at sales@ccmetalmesh.com.

PREV:

This is the last article

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)