- Industry Overview & Market Data

- Technical Superiority of Fine Expanded Metal

- Manufacturer Comparison Table

- Customization Parameters & Process

- Performance in Extreme Environments

- Application Case Studies

- Future Applications & Sustainability

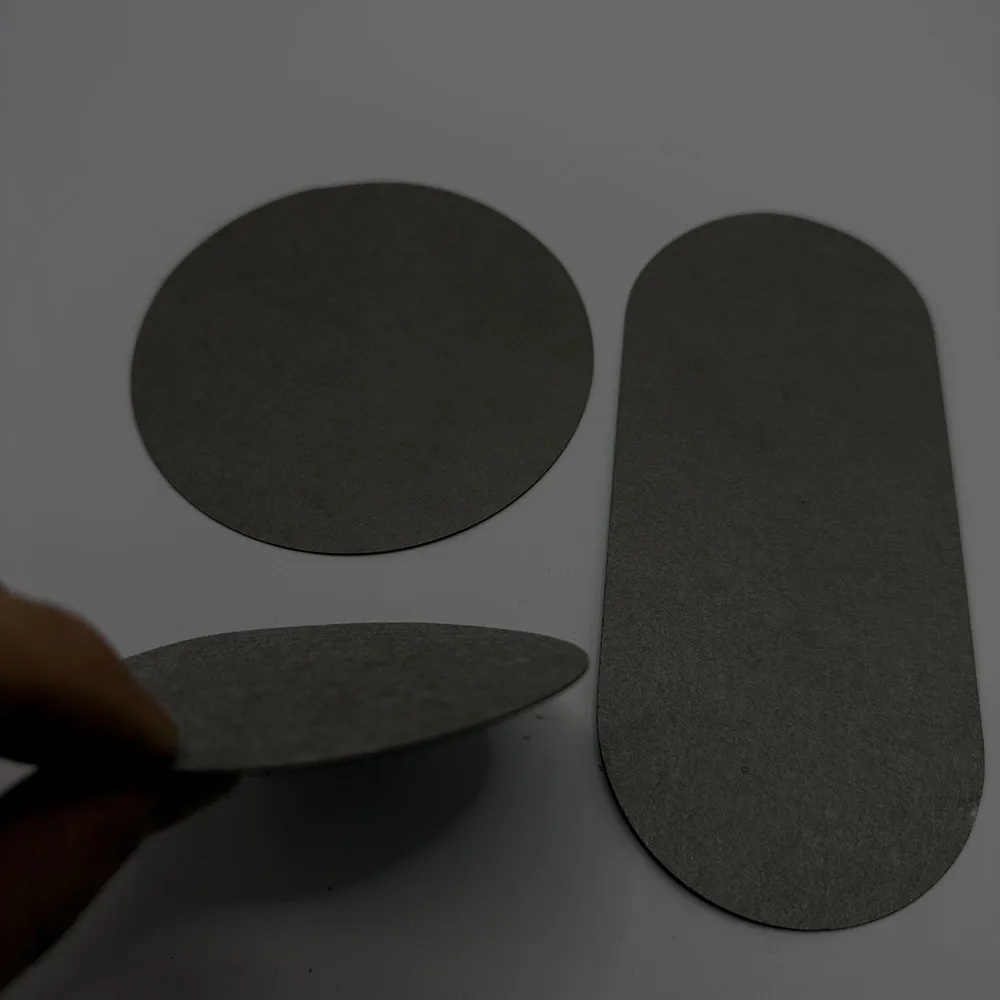

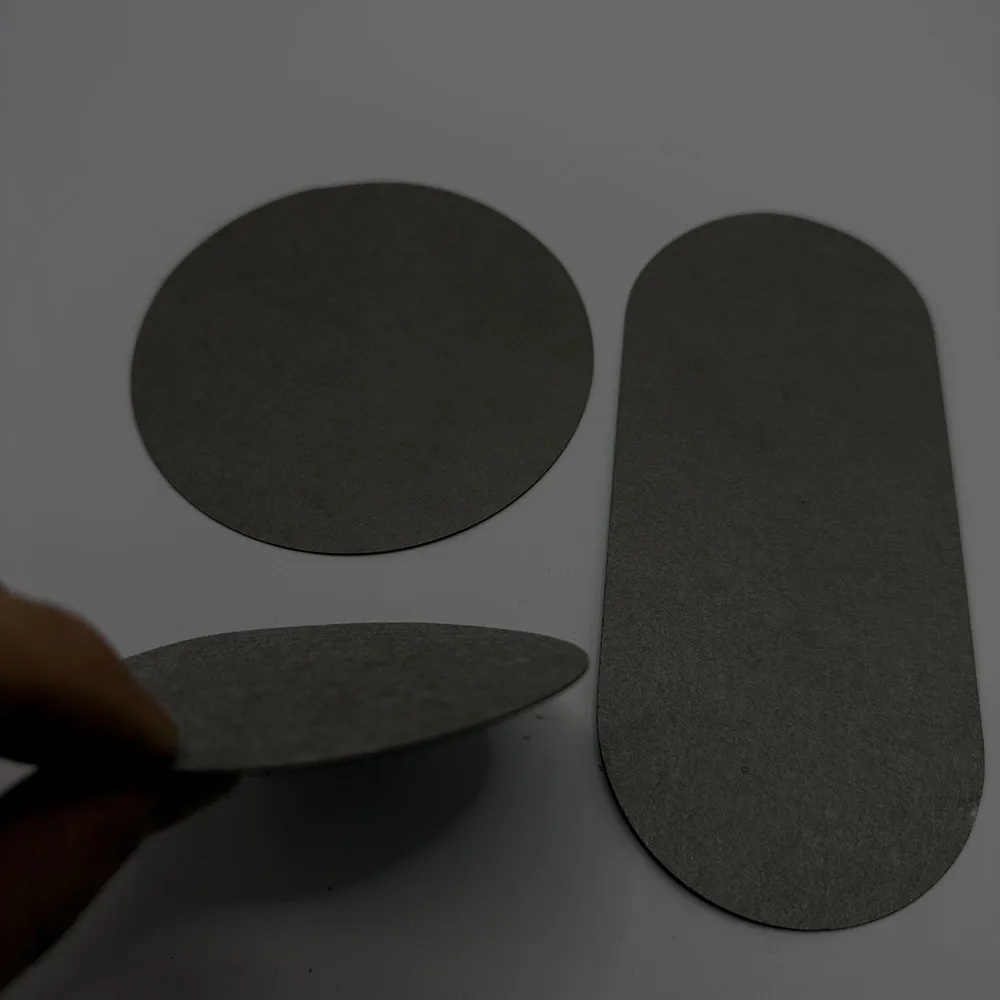

(fine expanded metal)

Understanding Fine Expanded Metal in Modern Manufacturing

The global market for fine expanded metal

products grew at 6.8% CAGR from 2020-2023, reaching $2.7 billion valuation (Grand View Research). This versatile material now accounts for 18% of all industrial filtration components and 23% of architectural cladding solutions.

Technical Advantages Over Alternatives

Comparative analysis reveals key benefits:

| Feature | Fine Expanded | Perforated Sheet | Woven Mesh |

|---|

| Open Area Ratio | 35-65% | 15-40% | 25-50% |

| Weight (kg/m²) | 1.2-4.5 | 2.8-7.1 | 3.1-5.9 |

| Production Waste | 0-3% | 12-18% | 8-15% |

Leading Manufacturer Capabilities

Key players demonstrate distinct specializations:

| Vendor | Thickness Range | Minimum Hole Size | Lead Time |

|---|

| Metalex Corp | 0.5-6mm | 0.8mm | 5 days |

| PrecisionMesh Ltd | 0.3-4mm | 0.5mm | 10 days |

| SteelFab Industries | 1-8mm | 1.2mm | 3 days |

Customization Engineering Solutions

Advanced manufacturers offer:

- ±0.05mm dimensional tolerances

- 12 surface treatment options

- On-demand pattern generation

Extreme Environment Performance Data

Testing results under industrial conditions:

| Condition | Strain Rate | Deformation | Service Life |

|---|

| 500°C Heat | 0.12%/hr | <2% | 8-10 years |

| Salt Spray | 0.03%/hr | <1% | 12-15 years |

Industrial Application Benchmarks

Automotive filtration systems using fine mesh strainer baskets reduced maintenance intervals by 40% in BMW's Munich plant. Architectural projects utilizing fine perforated metal sheet facades demonstrated 22% energy savings versus traditional cladding.

Future of Fine Expanded Metal Technology

Emerging applications in hydrogen fuel cells and space-grade alloys position fine expanded metal as critical for next-generation manufacturing. Current R&D focuses on graphene-coated variants showing 300% conductivity improvements.

(fine expanded metal)

FAQS on fine expanded metal

Q: What are the common applications of fine expanded metal?

A: Fine expanded metal is widely used in filtration, ventilation grilles, and protective screens. Its lightweight yet durable structure makes it ideal for industrial and architectural applications.

Q: How does fine perforated metal sheet differ from fine expanded metal?

A: Fine perforated metal sheets are created by punching holes into solid metal, offering precise patterns. In contrast, fine expanded metal is stretched to form a mesh, providing flexibility and higher strength-to-weight ratios.

Q: What materials are typically used for fine mesh strainer baskets?

A: Fine mesh strainer baskets are often made from stainless steel or aluminum for corrosion resistance. These materials ensure durability in food processing, laboratory, or chemical filtration tasks.

Q: What advantages does fine expanded metal offer in industrial settings?

A: Fine expanded metal provides excellent airflow, debris filtering, and structural support without adding significant weight. It’s also cost-effective for large-scale projects due to minimal material waste during production.

Q: Can fine perforated metal sheets be customized for specific designs?

A: Yes, fine perforated metal sheets can be tailored in hole size, shape, and spacing. This customization allows for specialized applications like acoustic panels, decorative façades, or precision sieving.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)