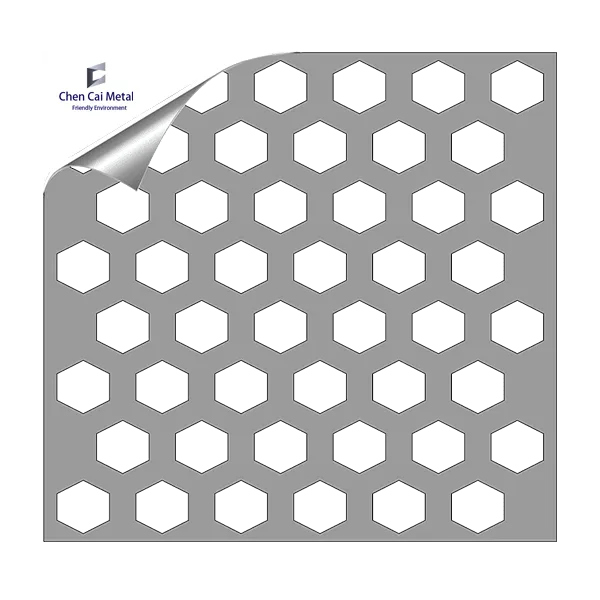

In the dynamic landscape of industrial manufacturing and architectural design, the demand for specialized materials that offer both functional superiority and aesthetic versatility is continuously on the rise. Among these, the hexagon perforated metal sheet stands out as a critical component, revered for its unique honeycomb pattern, exceptional strength-to-weight ratio, and broad applicability. This distinct product, often referred to interchangeably as honeycomb perforated sheet metal or hexagonal perforated sheet, is increasingly becoming the material of choice across diverse sectors, including petrochemical, automotive, HVAC, and architectural façade systems. The inherent geometric stability of the hexagonal opening, coupled with the precision of modern perforation techniques, allows for optimal light, air, and fluid flow while maintaining structural integrity. Industry trends indicate a significant surge in its adoption due to enhanced energy efficiency in ventilation systems, superior sound absorption capabilities in acoustic panels, and robust protective qualities in machinery guarding. The meticulous design and manufacturing of these sheets ensure not only high performance but also compliance with stringent international standards, making them an indispensable asset for forward-thinking engineering projects and innovative product development initiatives aiming for long-term sustainability and operational excellence in demanding environments. This material's adaptability to various finishes and materials further extends its utility, providing designers and engineers with unparalleled flexibility.

The production of high-quality hexagonal perforated metal, specifically the Hexagon 60° Perforated Sheet, involves a sophisticated multi-stage manufacturing process that prioritizes precision, material integrity, and adherence to exacting industry specifications. It commences with the careful selection of raw materials, which typically include stainless steel (e.g., 304, 316L), carbon steel, galvanized steel, aluminum, copper, brass, and even specialized alloys, chosen based on the intended application's demands for corrosion resistance, strength, and conductivity. Once the appropriate coil or sheet metal is selected, it undergoes a meticulous preparation phase, which may involve decoiling, leveling, and cleaning to ensure a pristine surface for perforation. The core of the manufacturing process is the precision punching or stamping operation. Advanced CNC-controlled perforating presses, equipped with custom-designed hexagonal dies, create the uniform 60° angle perforations. This high-speed, automated process ensures consistent hole size, pitch, and open area across the entire sheet, minimizing material distortion and maximizing panel integrity. Post-perforation, the sheets are typically degreased and deburred to remove any sharp edges or debris, followed by potential flattening to achieve desired flatness tolerances. Rigorous quality control measures are integrated throughout this entire process, including dimensional inspections (hole size, pitch, margin), material composition verification, and visual inspections for defects. Compliance with international standards such as ISO 9001 for quality management and ASTM/ANSI standards for material specifications and testing is paramount, ensuring that each hexagonal perforated sheet meets the highest benchmarks for performance and longevity, contributing to an extended service life in demanding industrial environments such as petrochemical plants, metallurgical facilities, and critical water treatment and drainage systems where precise filtration and robust structural elements are essential for operational efficiency and safety, alongside significant benefits in energy efficiency by optimizing airflow.

Understanding the critical technical parameters of honeycomb perforated sheet metal is fundamental for engineers and procurement specialists to specify the correct product for their unique application needs. Key specifications include material type, sheet thickness (gauge), hole size, hole arrangement (typically a 60-degree staggered pattern for hexagonal perforations), and the overall dimensions of the sheet. The "pitch" refers to the distance from the center of one hole to the center of the next, influencing the "open area" percentage, which is the total area of the holes divided by the total area of the sheet. A higher open area allows for greater flow (air, liquid, light) but may reduce structural rigidity, whereas a lower open area enhances strength and filtration capabilities. For instance, a common specification might be 1.5mm thickness, 5mm hexagonal hole, and 8mm pitch, yielding an open area of approximately 40%. The versatility of hex perforated metal also extends to its ability to be supplied in various finishes, including mill finish, polished, anodized, powder coated, or galvanized, each offering specific benefits like enhanced corrosion resistance or aesthetic appeal. Manufacturers often provide comprehensive data sheets detailing these parameters, ensuring that clients can precisely match the product to their operational requirements. Customization is a cornerstone of modern manufacturing for these sheets, encompassing not just hole size and pattern, but also specific alloys, custom sheet sizes, intricate cutting, forming, welding, and even specialized edge margins to facilitate installation in complex assemblies. This bespoke approach ensures that whether the application demands fine filtration, robust machine guarding, or specific acoustic properties, the chosen hexagonal perforated metal solution delivers optimal performance and long-term durability, minimizing maintenance and replacement costs throughout its extended service life.

| Parameter | Typical Range / Options | Description & Benefit |

|---|---|---|

| Material | Stainless Steel (304, 316L), Carbon Steel, Galvanized Steel, Aluminum, Copper, Brass | Selection based on corrosion resistance, strength, and environmental compatibility. 316L offers superior resistance to marine & chemical environments. |

| Sheet Thickness | 0.5mm to 10mm (0.02" to 0.4") | Determines structural rigidity and durability; thicker sheets for heavy-duty applications. |

| Hexagonal Hole Size (Side-to-Side) | 3mm to 50mm (0.12" to 2.0") | Affects filtration capabilities, flow rate, and aesthetic appearance. Smaller holes for finer filtration. |

| Pitch (Center-to-Center) | Typically 1.25x to 2x Hole Size | Distance between hole centers; directly impacts the open area and structural integrity. |

| Open Area Percentage | 20% to 70% (Commonly 30-50%) | Crucial for airflow, light transmission, and acoustic performance. Higher % for greater flow. |

| Standard Sheet Size | 1000x2000mm, 1220x2440mm, 1500x3000mm (Customizable) | Availability in standard sizes reduces waste; custom sizes minimize fabrication time on-site. |

| Surface Finish | Mill finish, Polished, Anodized, Powder Coated, Galvanized | Enhances corrosion resistance, aesthetics, and overall durability in diverse operating conditions. |

The unique characteristics of hexagonal perforated metal make it exceptionally versatile, finding critical applications across a spectrum of industries where performance, durability, and specialized functionality are paramount. In the architectural sector, it is extensively used for building facades, sunscreens, ceiling panels, and balustrades, offering an appealing aesthetic while providing shading, ventilation, and privacy, significantly contributing to the building's energy efficiency. For the automotive industry, these sheets are integrated into grilles, filters, and acoustic baffles due to their lightweight nature, excellent airflow properties, and sound dampening capabilities. Within industrial filtration systems—ranging from air and liquid filtration in chemical processing to particle separation in food and beverage production—the precise and uniform hexagonal openings provide superior filtration efficiency, resisting clogging and ensuring consistent flow rates, which extends equipment lifespan and reduces maintenance overheads. The material’s inherent strength and corrosion resistance also make it ideal for machinery guards and protective enclosures, ensuring operator safety without impeding visibility or ventilation. Furthermore, its application in HVAC systems for diffusers and grilles optimizes airflow distribution, contributing to better indoor air quality and reduced energy consumption. Clients consistently report enhanced operational longevity and reduced material fatigue, validating its superior engineering. For instance, a leading petrochemical firm recently adopted our 316L stainless steel hex perforated metal for their demanding filtration units, citing a 15% improvement in fluid processing efficiency and a notable reduction in equipment downtime due to the material's unparalleled resistance to corrosive agents.

Selecting the right manufacturer for your hexagonal perforated metal requirements is a critical decision that impacts project success, product longevity, and overall return on investment. A reputable supplier should demonstrate profound expertise in materials science, precision engineering, and quality control, evidenced by comprehensive industry certifications. Key indicators of an authoritative and trustworthy manufacturer include adherence to ISO 9001 quality management systems, certifications for specific material standards (e.g., ASTM, ANSI, EN), and a proven track record spanning several years, if not decades, in serving a diverse global clientele. For instance, our facility boasts over 20 years of experience in fabricating high-performance perforated metal products, consistently meeting and exceeding the most stringent industry benchmarks. We maintain rigorous internal quality assurance protocols, backed by third-party testing when necessary, to ensure every batch of hex perforated metal complies with specified tolerances and performance criteria. Furthermore, transparency in the supply chain, from raw material sourcing to final product delivery, is paramount. We provide detailed material test reports (MTRs) and certificates of conformity (CoCs) upon request, ensuring complete traceability and accountability. Our average lead time for standard products is 2-3 weeks, with expedited options available for urgent projects, communicated clearly upfront to manage expectations. Each product comes with a comprehensive warranty against manufacturing defects, underscoring our confidence in our product quality and commitment to customer satisfaction. We prioritize long-term partnerships, offering dedicated technical support from initial consultation through post-delivery service, ensuring that our clients receive not just a product, but a complete solution tailored to their operational needs and backed by unparalleled customer support, further building trust in every transaction.

The true value proposition of a leading supplier of hexagon perforated metal sheet lies not just in standard product offerings but in the ability to provide highly customized solutions that precisely address the unique and often complex requirements of diverse industrial projects. This involves a collaborative design process where our engineering teams work closely with clients to understand specific performance criteria, environmental challenges, and integration parameters. Customization can encompass bespoke hole sizes and patterns beyond standard hexagonal dimensions, specialized material grades for extreme conditions (e.g., high-temperature alloys, marine-grade stainless steel), unique sheet sizes and forms (e.g., curved panels, fabricated components), and an array of post-perforation treatments such as specialized coatings for enhanced chemical resistance or acoustic dampening. For instance, in a recent project for a major water treatment plant, we engineered custom large-format hexagonal perforated sheet filters with an optimized open area, leading to a 20% improvement in flow rate and reduced biofouling compared to previous solutions. Another notable application involved supplying custom-fabricated hexagonal panels for an iconic architectural landmark's facade, where precise hole alignment and a specific anodized finish were crucial for achieving the desired aesthetic and sun-shading properties, illustrating the blend of technical precision and artistic vision this material enables. These case studies underscore our commitment to delivering not just a product, but a meticulously engineered solution that contributes directly to our clients' operational efficiency, safety, and aesthetic objectives, solidifying our reputation as a trusted partner capable of tackling even the most challenging design and engineering problems with precision and innovation.

Q1: What are the primary advantages of using hexagon perforated metal sheet over other perforation patterns?

The hexagonal pattern offers a unique combination of high open area with excellent strength and structural stability due to its inherent geometric efficiency, resembling a honeycomb structure. This design facilitates superior airflow, light transmission, and acoustic properties compared to round or square perforations of similar open areas. Its aesthetic appeal also makes it highly favored in architectural applications, providing a modern and sophisticated look while maintaining critical functionality for ventilation, shielding, and filtration. The hexagonal shape distributes stress more evenly around the holes, potentially leading to increased fatigue resistance in certain applications. This geometric efficiency allows for more material to remain between holes for a given open area, contributing to enhanced durability and longer service life for applications in demanding environments.

Q2: How does material selection impact the performance and service life of hexagonal perforated sheet?

Material selection is paramount and directly correlates with the sheet's performance and longevity in specific environments. For highly corrosive settings, such as chemical processing or marine applications, stainless steel grades like 316L offer superior resistance. Carbon steel is a cost-effective choice for general structural applications where corrosion is not a primary concern or where protective coatings are applied. Aluminum is preferred for its lightweight properties and excellent corrosion resistance, making it ideal for architectural and transportation industries where weight reduction is critical. The choice of material also influences the sheet's formability, weldability, and heat resistance. A diligent assessment of the operating environment, temperature extremes, chemical exposure, and mechanical stress is essential to select the optimal material, ensuring extended service life and reliable performance, thereby preventing premature failure and reducing overall lifetime costs significantly.

Q3: What quality control measures are typically in place for the manufacturing of hexagonal perforated metal?

Reputable manufacturers employ a multi-faceted quality control system to ensure the consistent production of high-grade hexagonal perforated metal. This begins with rigorous inspection of raw materials upon arrival, verifying chemical composition and mechanical properties against specifications. During the perforation process, advanced sensors and camera systems continuously monitor hole size, pitch, and pattern accuracy. Post-perforation, sheets undergo thorough visual inspections for burrs, sharp edges, and surface imperfections. Dimensional checks using precision calipers and gauges verify overall sheet dimensions and flatness. Furthermore, statistical process control (SPC) methods are often utilized to maintain consistency across large production runs. Adherence to international standards like ISO 9001, combined with internal quality audits and potential third-party certifications, provides an assurance of product reliability and performance, ensuring the material meets all the specified criteria for critical applications.

PREV:

This is the last article