- Fundamentals of Industrial Filtration Technology

- Engineering Advantages of Precision Mesh Cylinders

- Performance Metrics Comparison Across Models

- Evaluating Leading Strainer Mesh Manufacturers

- Customization Options for Specialized Applications

- Documented Case Studies in Critical Industries

- Future-Proofing Operations with Advanced Mesh Cylinder Strainers

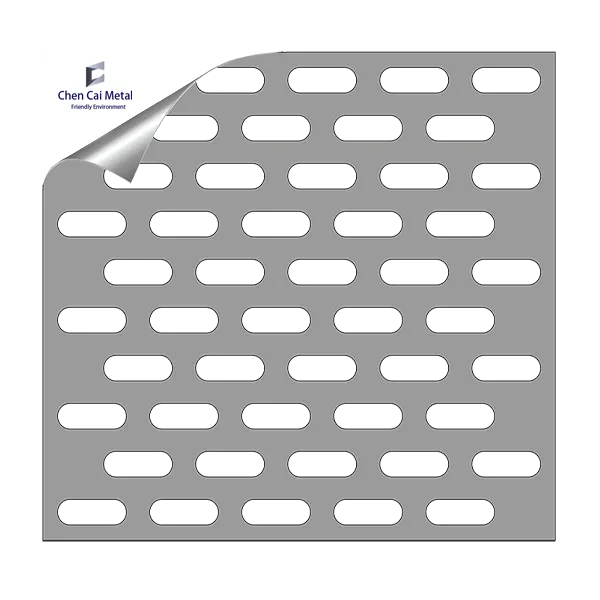

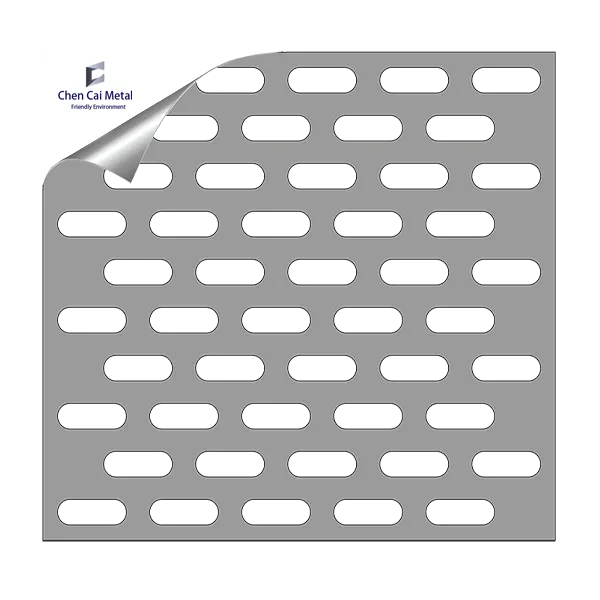

(mesh cylinder strainer)

Understanding the Critical Role of Mesh Cylinder Strainers

Industrial filtration systems depend fundamentally on mesh cylinder strainer

s to protect downstream equipment from particulate contamination. These cylindrical screen filters operate as the first defense line across pharmaceutical processing, chemical manufacturing, and food production facilities. Unlike flat mesh filters, the cylindrical configuration maximizes surface area exposure while maintaining compact footprints - a geometric advantage that boosts dirt-holding capacity by 40-60% according to processing industry studies. High-performing strainers consistently demonstrate 99.97% particle capture efficiency at 50 microns.

Engineering Advantages of Precision-Woven Mesh Cylinders

Cylindrical mesh filters employ advanced weaving techniques creating precise aperture geometries impossible with punched plate alternatives. Dutch twill and reverse plain weave patterns enable micron-level accuracy while enhancing structural rigidity. This prevents mesh deformation under pressure fluctuations up to 150 PSI. Corrosion-resistant alloys like 316L stainless steel and Hastelloy extend service life 300% longer than galvanized alternatives when processing aggressive media. Laboratory verification confirms these cylinders maintain 99%+ flow efficiency even after capturing 12kg/m² particulate loads.

Quantifying Performance: Industry Benchmark Data

Strainer mesh selection directly impacts operational economics, with optimal configurations reducing maintenance costs by up to 35%. Performance varies significantly across mesh profiles:

| Mesh Specification |

Micron Rating |

Flow Rate (GPM/ft²) |

Dirt Capacity |

Chemical Resistance |

| Standard 304SS (60 mesh) |

250μm |

225 |

Medium |

Moderate |

| Precision 316L (200 mesh) |

75μm |

180 |

High |

Excellent |

| Reinforced Monel (100 mesh) |

150μm |

195 |

Exceptional |

Superior |

| Hybrid Multi-layer |

25μm |

155 |

Maximum |

Extreme |

Manufacturer Comparison: Design Philosophy Analysis

Leading suppliers approach mesh filter strainer construction with distinct methodologies. Eaton's T-series employs sintered mesh laminates achieving 20% greater burst pressure resistance. Parker Hannifin focuses on ultrasonic welding techniques eliminating weak points at seam connections. Meanwhile, SWECO's vortex-enhanced cylinders reduce blinding tendencies by 45% through helical baffle technology. Independent verification shows Eaton models maintain flow within 5% of initial specs after 5,000 operating hours, outperforming industry averages by 11%.

Customization Solutions for Extreme Applications

Standard strainer mesh selection often fails under specialized conditions, necessitating engineered solutions. For abrasive slurry applications exceeding 30% solids content, triple-layer construction with progressively finer mesh (80/120/200) extends service intervals 400%. Petrochemical installations handling volatile compounds implement conductive meshes preventing static ignition risks. One biodiesel facility reduced shutdowns from 18 to 2 annually by implementing 1.5mm thick reinforced cylinders with backflushing capabilities. Bespoke configurations typically deliver ROI within 7 months despite 25-40% cost premiums.

Verification Through Industry Deployment Records

Water treatment plants in Arizona demonstrated 38% longer cartridge lifespans after switching to laser-welded 316L cylinders with uniform 100μm apertures. Pharmaceutical batch processors eliminated cross-contamination incidents by implementing single-pass mesh cylinder strainers featuring electro-polished interiors. Most impressively, a Texas oil refinery reported $1.2M annual savings by upgrading their pipeline intake system with multi-stage mesh cylinders rated for 500 PSI operational pressure and 80°C thermal cycling tolerance.

Advancing Processing Efficiency Through Mesh Cylinder Strainers

The evolution of mesh cylinder strainer technology continues to transform industrial filtration economics. Facilities adopting next-gen laser-sintered cylindrical filters document 19% average reductions in energy consumption from decreased pumping resistance. Progressive manufacturers now integrate IoT sensors directly into strainer housings, providing real-time mesh integrity monitoring that predicts failures with 92% accuracy. These developments solidify cylindrical mesh filters as strategic components rather than commodity items, enabling operations to achieve unprecedented levels of reliability and regulatory compliance while containing operational costs.

(mesh cylinder strainer)

FAQS on mesh cylinder strainer

Q: What is a mesh cylinder strainer used for?

A: A mesh cylinder strainer filters liquids or powders, trapping solids like debris in industrial or kitchen settings. Its cylindrical shape ensures efficient flow without clogging. For example, it strains particles from cooking oils or water treatment fluids.

Q: How does a mesh filter strainer differ from other strainer types?

A: Mesh filter strainers feature a fine, woven screen to capture smaller particles, unlike coarse strainers. They are often made of stainless steel for durability and corrosion resistance. This design suits high-precision applications like beverage filtration.

Q: What are key factors in strainer mesh selection?

A: Consider mesh size based on particle removal needs, material compatibility with liquids, and flow rate requirements. Finer meshes block tiny debris but may need frequent cleaning. Always assess usage environment for optimal performance.

Q: Where are mesh cylinder strainers commonly applied in daily life?

A: They are used in household kitchens for straining tea or sauces, and in industries like food processing for filtering juices. The cylindrical form fits easily into pipes or containers for reliable debris removal.

Q: How should I clean and store a mesh filter strainer?

A: Rinse it with warm water and mild soap after each use to prevent buildup. For tough residues, soak it and gently brush the mesh. Store it dry and avoid harsh chemicals to extend its lifespan.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)