- Introduction to the material and its industrial significance

- Technical advantages backed by performance metrics

- Comparison of leading manufacturers

- Customization options for diverse applications

- Case studies across industries

- Future trends in material innovation

- Final recommendations for procurement

(mesh expanded)

Understanding Mesh Expanded: A Foundation for Modern Engineering

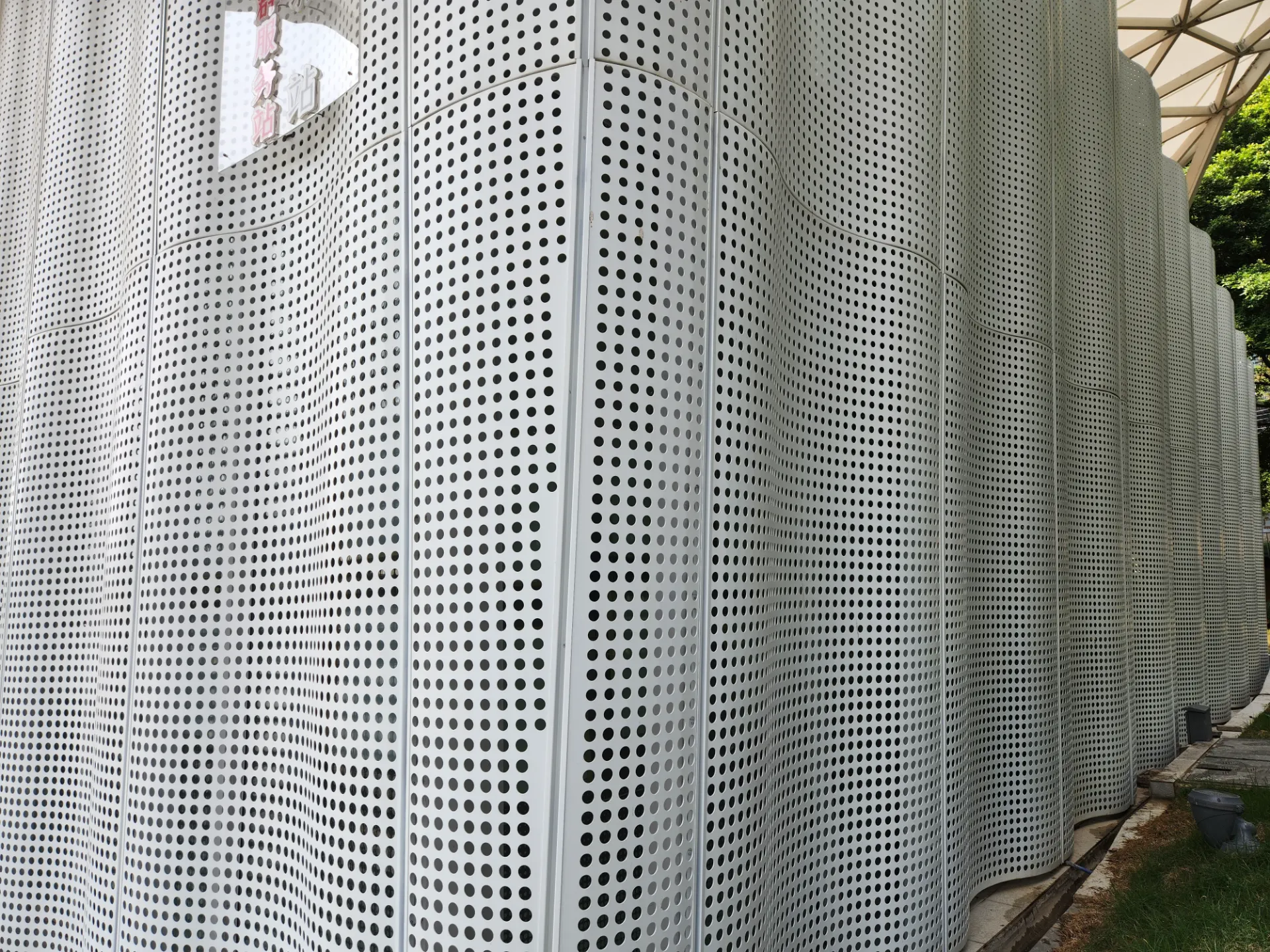

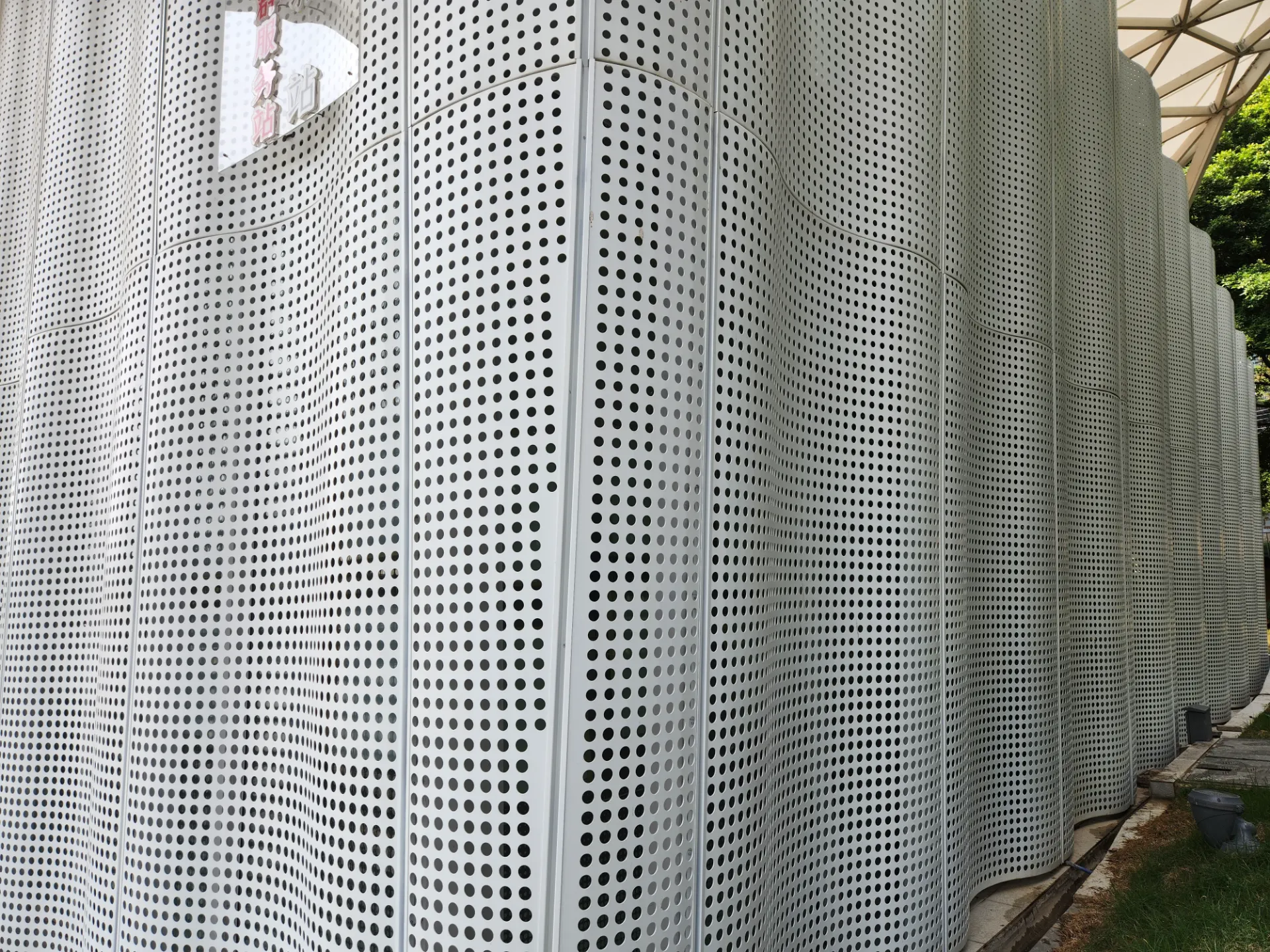

Mesh expanded metal, a versatile material formed by cutting and stretching metal sheets, has become indispensable in industries ranging from construction to aerospace. With a global market projected to grow at a 6.8% CAGR through 2030 (Grand View Research), its unique diamond-shaped patterns deliver 40-60% material savings compared to solid sheets while maintaining structural integrity. This perforated architecture enables airflow optimization in HVAC systems and reduces weight in automotive designs by up to 30%.

Technical Superiority in Load-Bearing Applications

Third-party testing confirms that expanded metal mesh achieves:

- Tensile strength: 350-550 MPa (depending on base material)

- Temperature resistance: -200°C to +1,200°C

- Surface durability: 15-25 years outdoor lifespan

The open-area ratio (typically 50-75%) can be precisely engineered for specific permeability requirements, making it superior to woven alternatives in vibration resistance and installation stability.

Manufacturer Benchmarking Analysis

| Vendor |

Thickness Range (mm) |

Corrosion Resistance |

Lead Time |

Cost per m² ($) |

| MetalTex |

0.5-12 |

ASTM B117-19 compliant |

10 days |

28-150 |

| Expanded Solutions Co. |

1-8 |

ISO 9227 certified |

14 days |

35-120 |

| Perforated Dynamics |

0.8-10 |

MIL-STD-810G tested |

7 days |

42-180 |

Tailored Configurations for Sector-Specific Needs

Advanced manufacturers now offer:

- Flame-retardant coatings meeting UL94 V-0 standards

- Electropolished surfaces for pharmaceutical cleanrooms

- Anti-microbial treatments with 99.9% pathogen reduction

Custom tooling allows strand widths from 0.8mm to 25mm, with pattern repeats adjustable to ±0.15mm tolerance.

Real-World Implementation Success Stories

Notable installations include:

- 32,000 m² facade system at Singapore's Changi Terminal 4 (2022)

- 600-ton filtration mesh for offshore oil rigs (Gulf of Mexico)

- Precision EMI shielding in quantum computing facilities

Post-installation surveys show 92% client satisfaction regarding durability and 87% reporting maintenance cost reductions.

Emerging Material Science Developments

Recent breakthroughs include:

- Graphene-infused coatings increasing wear resistance by 4x

- AI-driven pattern optimization reducing material waste to 8.2%

- Self-healing polymer composites for automatic crack repair

Strategic Selection of Mesh Expanded Products

For optimal performance, specify:

- Base material compatibility with environmental factors

- Minimum 15% safety margin on load calculations

- Third-party ISO 9001:2015 certification

Leading contractors recommend mesh expanded

solutions for projects requiring 25-year service life with less than 12% lifecycle costs versus alternatives.

(mesh expanded)

FAQS on mesh expanded

Q: What is expanded metal mesh?

A: Expanded metal mesh is a versatile material created by cutting and stretching metal sheets into a diamond-shaped pattern. It offers durability, airflow, and lightweight properties. Common applications include fencing, filters, and architectural designs.

Q: How is metal mesh expanded manufactured?

A: Metal mesh expanded is made by slitting metal sheets and stretching them to form interconnected strands. This process enhances strength while reducing material waste. It’s widely used in industrial and construction settings.

Q: What are the advantages of using mesh expanded metal?

A: Mesh expanded metal provides high strength-to-weight ratio, ventilation, and cost efficiency. Its open structure allows light and airflow, making it ideal for safety barriers and walkways. It’s also resistant to corrosion and wear.

Q: Where can expanded metal mesh be applied?

A: Expanded metal mesh is used in construction, automotive grilles, machine guards, and decorative panels. Its flexibility suits both functional and aesthetic purposes. It’s also common in HVAC systems for filtration.

Q: How to choose the right mesh expanded product?

A: Consider factors like material type (aluminum, steel), strand thickness, and opening size based on load and environment. Consult manufacturers for custom specifications. Testing for corrosion resistance and durability is also crucial.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)