- The Critical Role of Filtration in Modern Industry

- Data Impact: The True Cost of Inefficient Filtration

- Technical Design Advantages of Mesh Filtration Systems

- Comparative Analysis of Industry-Leading Manufacturers

- Tailored Solutions: Matching Filter Configuration to Application

- Field Applications and Operational Case Studies

- Advancing Fluid Management with Mesh Type Filters

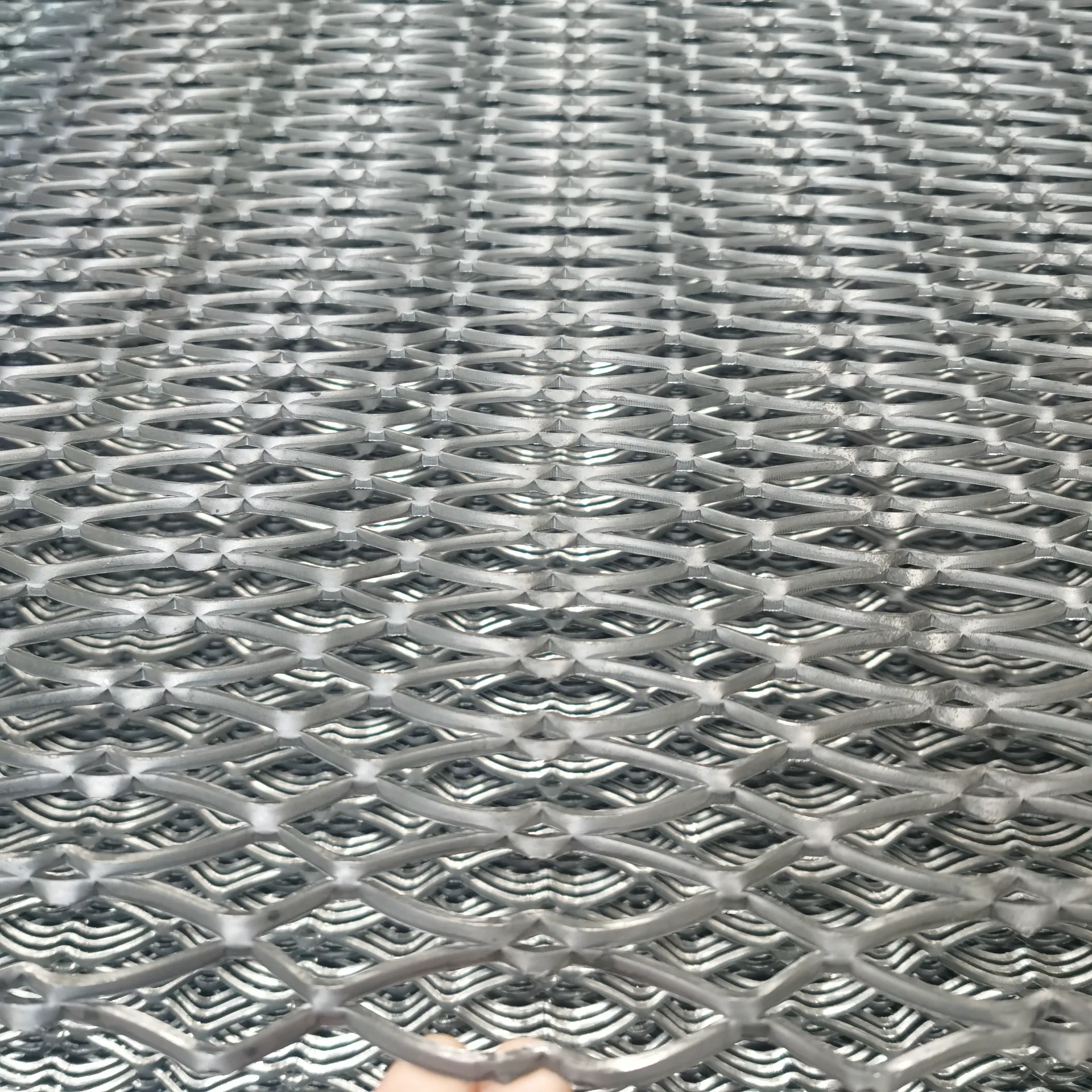

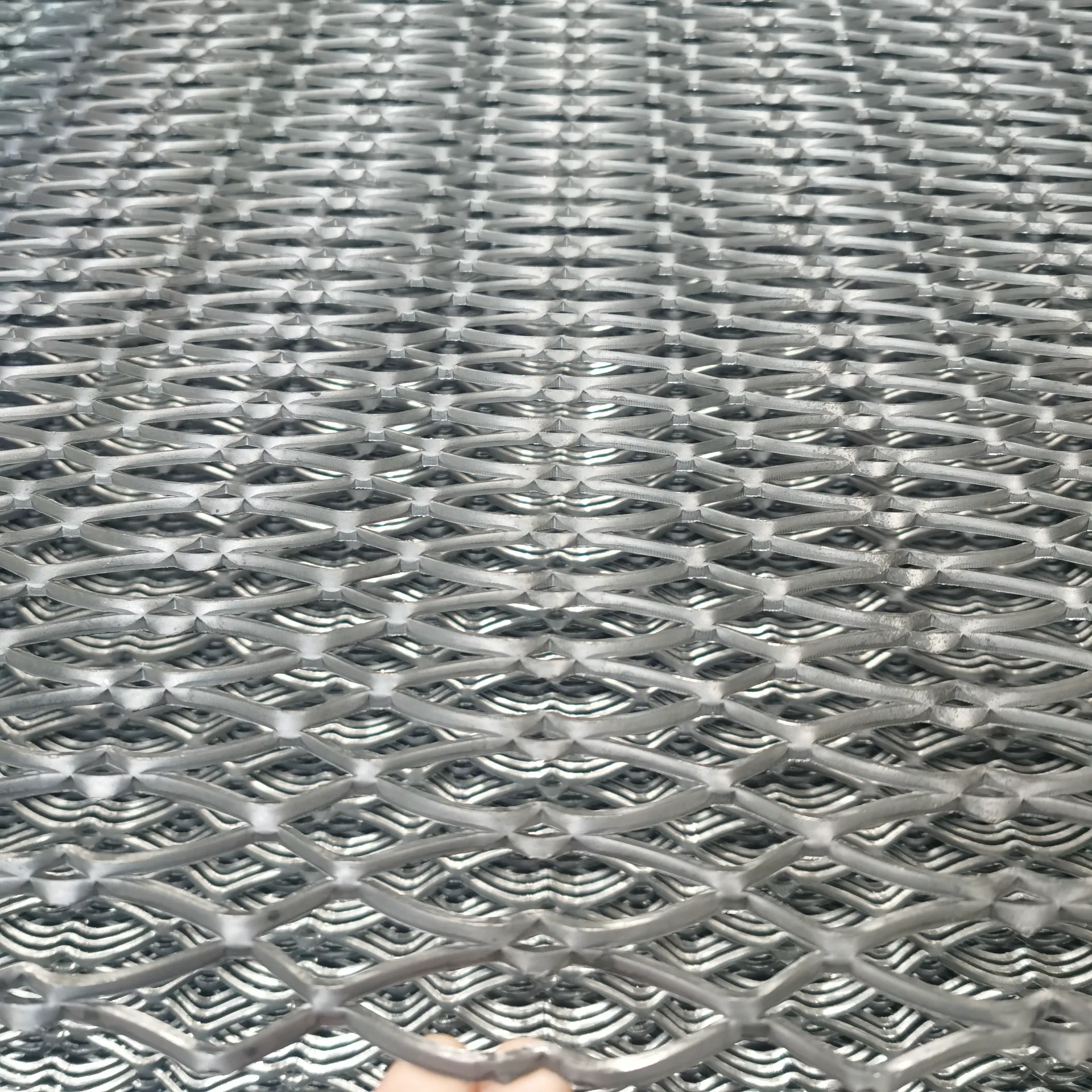

(mesh type filter)

The Critical Role of Mesh Type Filter Solutions in Industrial Systems

Industrial filtration forms the frontline defense against particulate contamination in fluid processing systems. Mesh type filter configurations have evolved beyond simple strainers to become engineered components critical for protecting downstream equipment. Modern wire mesh type filter

systems integrate multiple filtration layers with graduated micron ratings, creating progressive filtration barriers. This layered approach captures particles in stages rather than at a single filter surface. Operators can achieve filtration efficiencies exceeding 99.6% for particles larger than 40 microns. Industry surveys indicate that 68% of premature pump failures stem from particulate contamination, making high-performance filtration not merely beneficial but operationally essential.

The construction of premium mesh filters utilizes woven Dutch weave patterns with non-reactive alloys. This weave configuration provides uniform pore distribution while maintaining high flow rates at low-pressure differentials. Unlike simple perforated plates, the precise 90° crossover points in woven meshes prevent particle deformation that leads to screen blinding. Most industrial-grade mesh filters feature dual-layer construction combining coarse backing support meshes with fine filtration layers. This architecture withstands working pressures up to 1500 psi without risking mesh blowout.

Data Impact: The True Cost of Inefficient Filtration

Quantitative analysis reveals filtration failures create cascading system consequences. Studies by the Hydraulic Institute demonstrate contamination-related issues annually:

- Cause 1.2 million hours of unplanned equipment downtime

- Reduce hydraulic efficiency by 15-23% due to flow restrictions

- Increase energy consumption by 7-18% in affected systems

- Account for 37% of all mechanical seal replacements

The economic impact becomes even more evident when examining comparative life-cycle costs. While mesh filters represent 5-7% of initial system capital expenditure, they influence 89% of maintenance budgets over five years of operation. Industrial facilities implementing precision filtration systems report tangible ROI within 10-18 months through reduced component replacement frequency and extended service intervals. These validated metrics underscore why filtration specification should never be an afterthought in system design.

Technical Design Advantages of Mesh Filtration Systems

Contemporary mesh type filter designs incorporate significant advances over traditional straining methods. The core technical differentiators include:

Multi-layer Construction: By stacking varying mesh densities, filters achieve depth filtration rather than surface straining alone. The coarser 150-micron support layer provides structural stability while the finer 20-40 micron filtration layer captures hazardous particulates. This configuration offers a 300% improvement in contaminant holding capacity compared to single-layer alternatives.

Optimized Flow Dynamics: Computational Fluid Dynamics modeling enables shaped basket designs with gradient cone geometry. The progressive increase in filter surface area along the flow path prevents pressure spikes during high-flow conditions. Cone type strainer models demonstrate significantly lower pressure drop characteristics - typically 0.05-0.1 bar compared to 0.2-0.5 bar in conventional basket strainers.

Material Science Innovations: Advanced duplex stainless steels (EN 1.4462) provide superior corrosion resistance while maintaining micro-smooth surface finishes below 0.8 Ra. Non-metallic variants employ PEEK polymer matrices when chemical compatibility requirements exceed metal capabilities. These engineering polymers withstand pH extremes from 0.5 to 14 without degradation.

Comparative Analysis of Industry-Leading Manufacturers

| Manufacturer |

Filtration Efficiency |

Maximum Pressure |

Temp Range |

Material Options |

Cleaning Interval |

| Filtrex Systems |

99.9% @ 25 micron |

100 bar |

-40°C to 260°C |

316L, Alloy C-276 |

1200 operating hrs |

| OmniFilter Technologies |

99.6% @ 40 micron |

65 bar |

-29°C to 180°C |

304SS, Hastelloy |

900 operating hrs |

| HydroPure Solutions |

99.8% @ 30 micron |

86 bar |

-50°C to 315°C |

316Ti, Monel |

1500 operating hrs |

| Triple R Engineering |

99.4% @ 50 micron |

40 bar |

-10°C to 150°C |

304SS, Carbon Steel |

600 operating hrs |

Pressure tolerance directly correlates with mesh support architecture - premium manufacturers utilize patented backing systems featuring radial reinforcement ribs. High-tier suppliers offer surface passivation treatments achieving salt spray resistance exceeding 1500 hours per ASTM B117 standards. When selecting, consider hydraulic shock resistance ratings which vary from 1.5x to 3.5x working pressure across manufacturers.

Tailored Solutions: Matching Filter Configuration to Application

Customizing mesh filters optimizes performance for specific operational parameters. Primary configuration variables include:

Pore Geometry Configuration:

- Square mesh weave: Standard 90° crossings for general applications

- Dutch twilled weave: Offset crossings increase particle retention

- Reverse Dutch weave: Ultra-fine surface filtration layer

Form Factor Selection:

- Basket strainers: Horizontal/vertical orientation options

- Cone type strainer: Ideal for high-solids applications

- Drop-in cartridges: Rapid replacement designs

Material selection follows rigorous chemical compatibility protocols. Pharmaceutical applications mandate crevice-free construction with Ra ≤ 0.4 µm surface finish. Offshore systems require material certifications for H2S service according to NACE MR0175 standards. Highly viscous media necessitate enlarged flow areas and cone angles exceeding 45°. These customizations routinely extend service life by 50-75% compared to standard off-the-shelf units.

Field Applications and Operational Case Studies

Oil Refinery Cooling Systems

A Gulf Coast refinery retrofitted tertiary cooling loops with 120-micron wire mesh type filter arrays. Resultant benefits included a 55% reduction in heat exchanger tube fouling and extended chemical treatment intervals from 30 to 90 days. The implementation reduced maintenance labor requirements by 320 man-hours monthly.

Municipal Water Processing

Berlin's water authority deployed cone type strainer systems with automatic backflush capabilities. The installation eliminated six daily manual cleaning cycles while protecting centrifugal pumps from river debris. Particle ingress decreased by 97% while energy consumption per cubic meter treated declined by 11%.

Pharmaceutical Process Streams

Vaccine manufacturing processes integrated duplex stainless steel mesh filters downstream of bioreactors. Validation testing demonstrated complete elimination of 15-micron cell debris without compromising flow requirements. This advancement reduced batch failure rates from 3.2% to under 0.5% annually.

Advancing Fluid Management with Mesh Type Filter Systems

The technological progression of mesh type filter solutions continues to elevate industrial fluid processing standards. Leading manufacturers are developing predictive monitoring systems incorporating pressure transducers with IoT-enabled analytics. These innovations shift maintenance protocols from scheduled replacements to condition-based servicing, potentially reducing spare parts inventories by 40%.

The future points toward specialized hybrid designs combining metal mesh substrates with polymer nanofiber coatings. Initial prototypes demonstrate simultaneous filtration of 5-micron particulates and 0.5-micron microorganisms - a combination previously requiring separate filtration stages. As global industry adopts more sustainable practices, filtration engineers focus on designs facilitating 99%+ material recovery during cleaning cycles. This evolution transitions mesh filters from protective devices toward integral resource conservation tools. The continuous innovation ensures mesh filtration remains indispensable across ever-changing industrial requirements.

(mesh type filter)

FAQS on mesh type filter

Here are 5 sets of FAQs focused on the core keyword "mesh type filter" and related terms like "wire mesh type filter," "mesh type filter," and "cone type strainer," presented in HTML-rich text format as requested. Each FAQ includes a question with an H3 tag starting with "Q:" and an answer starting with "A:", with both the question and answer limited to three sentences or less.

Q: What is a mesh type filter?

A: A mesh type filter uses a perforated metal or plastic screen to trap particles in liquids or gases. It provides efficient filtration in industrial or domestic applications, such as pipelines. Different mesh sizes target specific debris sizes based on the required micron rating.

Q: How does a wire mesh type filter work?

A: A wire mesh type filter features woven metal wires forming a robust screen that blocks solid contaminants during fluid flow. It operates by allowing fluids to pass through while retaining particles on the mesh surface. This design is durable and ideal for high-pressure environments like chemical processing.

Q: When should I use a cone type strainer?

A: Use a cone type strainer for applications requiring coarse filtration of fluids in pipelines, such as wastewater systems or oil and gas. Its conical shape efficiently collects debris with low resistance to flow. This strainer protects pumps and valves from clogs while being easy to inspect and clean.

Q: What are the key benefits of a mesh type filter?

A: Mesh type filters offer reliable particle removal through customizable screen sizes to match filtration needs. They are cost-effective, reusable, and reduce downtime in systems like irrigation or food processing. Proper maintenance ensures longevity and consistent flow rates across various operating conditions.

Q: How do I maintain a wire mesh type filter?

A: Maintain a wire mesh type filter by routinely cleaning it with water or solvents to prevent buildup and blockages. Check for damage like tears or corrosion during inspections to ensure peak efficiency. Follow manufacturer guidelines for replacement intervals to maintain optimal performance in demanding settings.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)