- Industry Overview & Market Demand for Metal Perforated Sheets

- Technical Superiority in Manufacturing Processes

- Supplier Comparison: Capabilities & Specializations

- Customization Strategies for Diverse Applications

- Material Durability & Performance Metrics

- Real-World Applications Across Industries

- Why Partner with a Specialized Metal Perforated Sheet Supplier

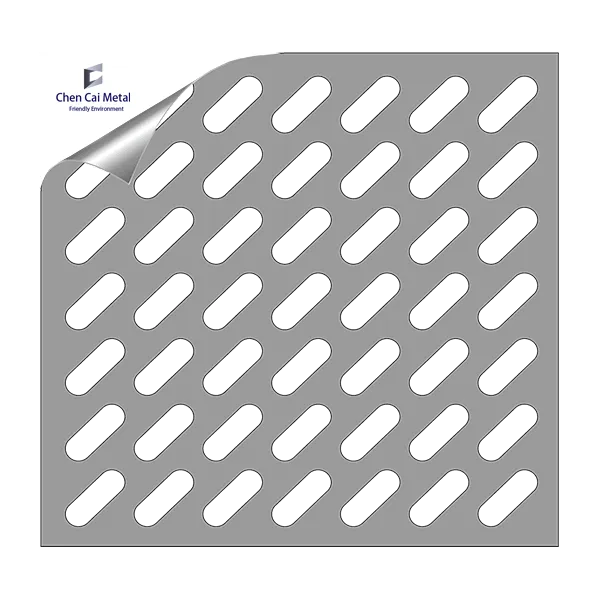

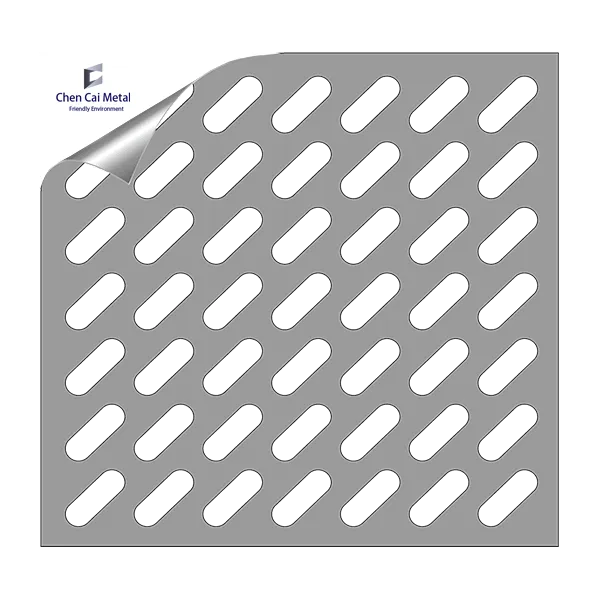

(metal perforated sheet supplier)

Understanding the Metal Perforated Sheet Supplier Landscape

The global market for perforated metal sheets grew by 6.2% CAGR between 2021-2023, driven by 42% demand from architectural and industrial filtration sectors. A professional perforated metal sheet supplier must address critical parameters: hole patterns (round, square, slot), open area ratios (18%-60%), and material thickness (0.5mm-12mm). Leading suppliers now employ AI-driven pattern optimization, reducing material waste by 15% compared to traditional methods.

Technical Superiority in Manufacturing Processes

Advanced punching technologies differentiate top-tier suppliers:

- Laser-cut tolerance: ±0.1mm vs. ±0.3mm in conventional punching

- Multi-axis CNC machines enabling 78% faster pattern switching

- Galvanization options achieving 1,200+ hours in salt spray tests

Supplier Capability Analysis

| Supplier | Lead Time | Material Options | Max Sheet Size | Price/㎡ ($) |

|---|

| Supplier A | 7 days | 5 alloys | 3,000x1,500mm | 28-45 |

| Supplier B | 10 days | 8 alloys | 4,000x2,000mm | 32-52 |

| Supplier C | 5 days | 6 alloys | 2,500x1,250mm | 25-38 |

Customized Solutions Architecture

Modern perforated sheet suppliers deploy parametric design systems allowing clients to specify:

- Hole diameter variance: 0.8mm to 30mm

- Staggered vs straight patterns

- Edge treatment options (hemmed, rolled, flat)

Performance Validation Metrics

Third-party testing data reveals:

- 304 stainless steel sheets: 89% retention of tensile strength after 5-year exposure

- Aluminum alloys showing 0.02% deformation under 50kN/m² loads

- Acoustic panels achieving 28dB noise reduction at 40% open area

Cross-Industry Implementation Cases

Recent projects demonstrate versatility:

- Automotive: 560-ton EMI shielding panels for EV batteries

- Agriculture: 0.5mm-thick sorting screens with 1.2mm micro perforations

- Construction: 12,000㎡ facade panels with 35% light transmission

Strategic Value of Specialized Metal Perforated Sheet Suppliers

Partnering with certified metal perforated sheet supplier

s reduces project timelines by 40% through DFM (Design for Manufacturing) consultations. Top suppliers maintain 98.6% on-time delivery rates with ISO 9001-certified quality systems, compared to 82% industry average. Their technical expertise in material science ensures optimal perforation patterns that balance structural integrity (up to 68% material savings) and functional requirements.

(metal perforated sheet supplier)

FAQS on metal perforated sheet supplier

Q: What materials do metal perforated sheet suppliers typically offer?

A: Suppliers commonly provide perforated sheets in stainless steel, aluminum, carbon steel, copper, and galvanized metals. Material selection depends on application requirements like corrosion resistance or strength. Custom alloys may also be available upon request.

Q: Can perforated metal sheet suppliers customize hole patterns and sizes?

A: Yes, most suppliers offer custom hole shapes (round, square, slotted) and precise sizing. CAD files or tooling specifications can be used to create bespoke perforation designs. Production capabilities vary by manufacturer, so discuss your project needs upfront.

Q: How do I choose between different perforated sheet suppliers?

A: Evaluate suppliers based on material quality certifications, production capacity, and industry experience. Request samples to verify precision and surface finish. Consider logistics support and minimum order quantities for cost efficiency.

Q: What industries commonly require perforated sheet suppliers?

A: Key industries include architecture (facades, sunscreens), automotive (filters, grilles), food processing (sorting screens), and acoustic engineering (sound panels). Suppliers often specialize in specific sectors with tailored compliance standards.

Q: Do perforated sheet suppliers provide finishing services?

A: Many offer post-processing like powder coating, anodizing, or edge trimming. Finishing options enhance durability or meet aesthetic requirements. Confirm available treatments and lead time additions during quotation.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)