- Introduction to Ornamental Perforated Sheet Metal

- Technical Advancements in Metal Processing

- Comparing Manufacturers: Data-Driven Insights

- Custom Solutions: Tailoring for Every Project

- Application Cases Across Key Industries

- Design Considerations for Optimal Performance

- Conclusion: The Future of Ornamental Perforated Sheet Metal

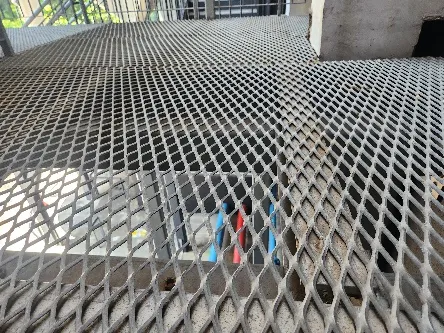

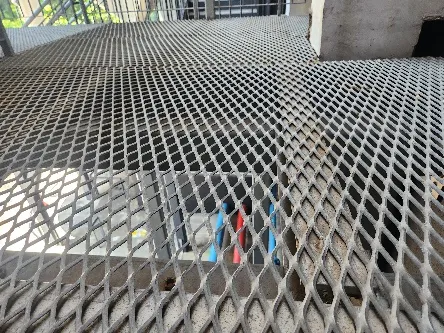

(ornamental perforated sheet metal)

Introduction to Ornamental Perforated Sheet Metal

Ornamental perforated sheet metal stands at the forefront of modern architectural and industrial design. This versatile product combines aesthetics with functionality, offering limitless design possibilities for both interior and exterior spaces. The manufacturing process involves punching or stamping patterns, such as diamonds, circles, and custom geometric shapes, into materials like stainless steel, aluminum, or brass. Today’s market is driven by the increasing demand for materials that bring unique visual appeal while maintaining performance characteristics such as corrosion resistance and structural strength.

The global perforated metal sheet market was valued at over USD 8.5 billion in 2023 and is projected to reach USD 12.4 billion by 2030, growing at a CAGR of 5.3%. This growth is spurred by rising adoption in architecture, infrastructure, and industrial process applications. Ornamental expanded metal adds another layer to the spectrum, offering strength-to-weight ratio advantages through its unique lattice formation. Stainless steel perforated sheet, a subset, is recognized for its exceptional durability and resistance to harsh environments, essential for high-traffic and corrosive settings.

Technical Advancements in Metal Processing

The evolution of manufacturing technologies has transformed the ornamental expanded metal and perforated metal sheet industry. Modern CNC punching and laser cutting allow for micro-perforations (<0.5 mm diameter) and highly detailed patterns, enabling ultra-precise architectural design.

High-tolerance processes now deliver uniform hole patterns, reduced edge burrs, and improved flatness, resulting in enhanced visual consistency and mechanical performance. Stainless steel perforated sheet can reach tensile strengths up to 580 MPa, enabling its use in critical load-bearing applications. These technological advancements minimize waste, improve processing speeds by up to 35%, and expand the range of workable metals, including titanium and specialized alloys. Today’s sheets often meet ASTM A240 or EN 10088 standards, ensuring reliable structural and aesthetic outcomes.

Comparing Manufacturers: Data-Driven Insights

Selecting the right manufacturer is crucial for achieving optimal product quality and cost-efficiency. Below is a comparative table featuring key global producers of ornamental perforated sheet metal

, evaluating their capabilities across technical and service dimensions.

| Manufacturer |

Material Options |

Minimum Hole Diameter |

Sheet Thickness Range (mm) |

Custom Pattern Support |

Average Lead Time |

Warranty (years) |

| AccuMetal Design |

SS, Aluminum, Brass |

0.5 mm |

0.5 - 6.0 |

Yes |

7 days |

5 |

| FlexiPerforate Inc. |

SS, Aluminum, Titanium |

0.3 mm |

0.4 - 8.0 |

Yes (Advanced) |

10 days |

3 |

| EuroMesh Systems |

SS, Mild Steel, Copper |

0.7 mm |

0.8 - 10.0 |

Limited |

12 days |

4 |

| OrnateSheet Tech |

Aluminum, SS, Brass, Bronze |

0.6 mm |

0.5 - 5.0 |

Yes |

8 days |

5 |

The comparison indicates that FlexiPerforate Inc. boasts the smallest achievable hole diameter and broadest material adaptability, making it ideal for high-precision architectural projects. AccuMetal Design and OrnateSheet Tech excel in lead time and warranty, ensuring both quality and reliability for fast-track construction or refurbishment needs.

Custom Solutions: Tailoring for Every Project

One of the standout features of ornamental perforated sheet metal is the vast potential for customization. Manufacturers offer a range of patterning options—circular, square, slotted, or completely bespoke geometric forms—that can be adapted to suit the functional and decorative requirements of a project. Sheet metals, such as stainless steel, are frequently chosen for custom fabrications due to their ease of processing and long-term durability.

Customization extends to aspects such as panel sizing (standard up to 3000 x 1500 mm, with larger options on request), edge finish (plain, rolled, or reinforced), and surface treatment (powder coating, anodizing, or polishing). Perforation open area can be set from 10% to over 60%, striking the right balance between visibility, light filtration, acoustics, and airflow. For projects demanding unique branding or artistic flair, laser-cut logos and multi-layer composite sheets are also available. In addition, manufacturers can conduct structural simulations, ensuring that ornate perforations preserve adequate load-carrying capacity for safety and compliance.

Application Cases Across Key Industries

Ornamental expanded metal and perforated metal sheet options have found their way into a wide array of project types, from architectural icons to robust industrial installations.

In building façades, these materials serve as both protective barriers and arresting design features, integrating sun-shading with visual texture. Over 52% of contemporary office complexes in Europe now incorporate architectural perforated panels for natural lighting enhancement and HVAC optimization.

Within interior design, designers specify intricate stainless steel perforated sheet walls, partition screens, and staircase balustrades. The hospitality sector adopts these as ceiling panels and signage, boosting brand identity. In transportation infrastructure, such as metro stations and airports, expanded metal panels withstand heavy wear while enabling easy cleaning and vandal resistance. The food processing and pharmaceutical industries rely on these materials for hygiene-critical equipment claddings, where up to 80% of machine guards employ perforated stainless steel for its non-corrosive, easy-to-sanitize features.

Case study: The Doha Metro in Qatar utilizes more than 25,000 sqm of decorative perforated aluminum panels in its passenger terminals, reducing internal temperatures by an average of 4°C and saving an estimated 18% on cooling energy bills annually.

Design Considerations for Optimal Performance

Achieving the best results with ornamental perforated and expanded metals requires attention to several technical and aesthetic factors:

1. Material Choice: Stainless steel offers leading corrosion resistance; aluminum is valued for its lightweight and formability; brass and bronze suit luxury interiors.

2. Pattern Geometry: The shape, size, and open area percentage directly affect air, water, and light permeability, as well as the structural rigidity of the sheet.

3. Thickness and Strength: Designers must balance visual delicacy with the necessary robustness for the intended application.

4. Surface Finish: Powder-coating and anodizing add color and further corrosion protection.

5. Sustainability: Many manufacturers offer sheets manufactured from up to 70% recycled metals, contributing to LEED and BREEAM certification.

An optimal specification is informed by a combination of visual goals, environmental exposure, and compliance with relevant building or industry codes.

Conclusion: The Future of Ornamental Perforated Sheet Metal

The ornamental perforated sheet metal landscape continues to innovate, driven by the demands of forward-thinking architects, interior designers, and industry leaders. As fabrication techniques advance, precision, and customization options become even more accessible—enabling each project to achieve a signature appearance without sacrificing performance or sustainability.

With growing attention to environmental responsibility and evolving design standards, new alloys and coatings emerge, extending the use of these materials into more demanding and creative contexts. Industry data highlights an upward trajectory, with the adoption of stainless steel perforated sheet and expanded metal expected to rise by over 6% annually through the next decade. By choosing experienced manufacturers and leveraging technical expertise, stakeholders can ensure that their installations exemplify both style and functionality.

The adoption of ornamental perforated sheet metal signifies a commitment to integrating art with engineering, creating spaces that are as enduring as they are visually compelling.

(ornamental perforated sheet metal)

FAQS on ornamental perforated sheet metal

Q: What is ornamental perforated sheet metal used for?

A: Ornamental perforated sheet metal is commonly used for decorative screens, facades, and architectural features. It combines visual appeal with light filtration and airflow. It is suitable for both interior and exterior applications.

Q: How does ornamental expanded metal differ from perforated metal sheet?

A: Ornamental expanded metal is created by slitting and stretching metal to form mesh patterns. In contrast, perforated metal sheets have holes punched or stamped into them in various designs. Both offer unique aesthetics and functionality for architectural projects.

Q: Can I get stainless steel perforated sheet metal for outdoor use?

A: Yes, stainless steel perforated sheet metal is highly durable, corrosion-resistant, and ideal for outdoor environments. It maintains its appearance with minimal maintenance. This makes it a popular choice for facades, fencing, and exterior accents.

Q: What design options are available for ornamental perforated sheet metal?

A: Design options include a wide range of hole shapes such as round, square, hexagonal, and decorative patterns. Custom designs are often available to suit specific architectural needs. Finishes can include powder coating, anodizing, or brushed surfaces.

Q: Is perforated metal sheet suitable for ventilation and privacy?

A: Yes, perforated metal sheet allows air flow while providing a degree of privacy and security. The size and arrangement of perforations can be tailored to achieve the desired effect. It's often used in screens, partitions, and cladding for this reason.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)