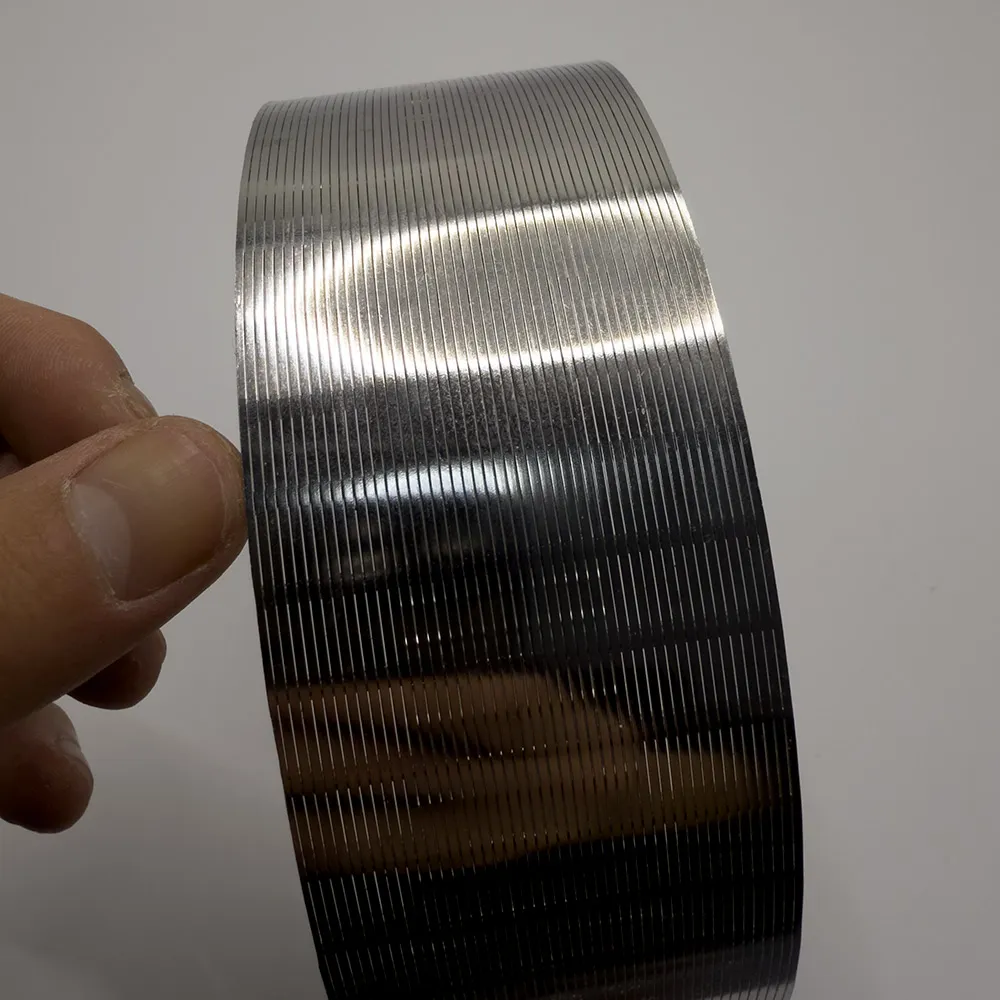

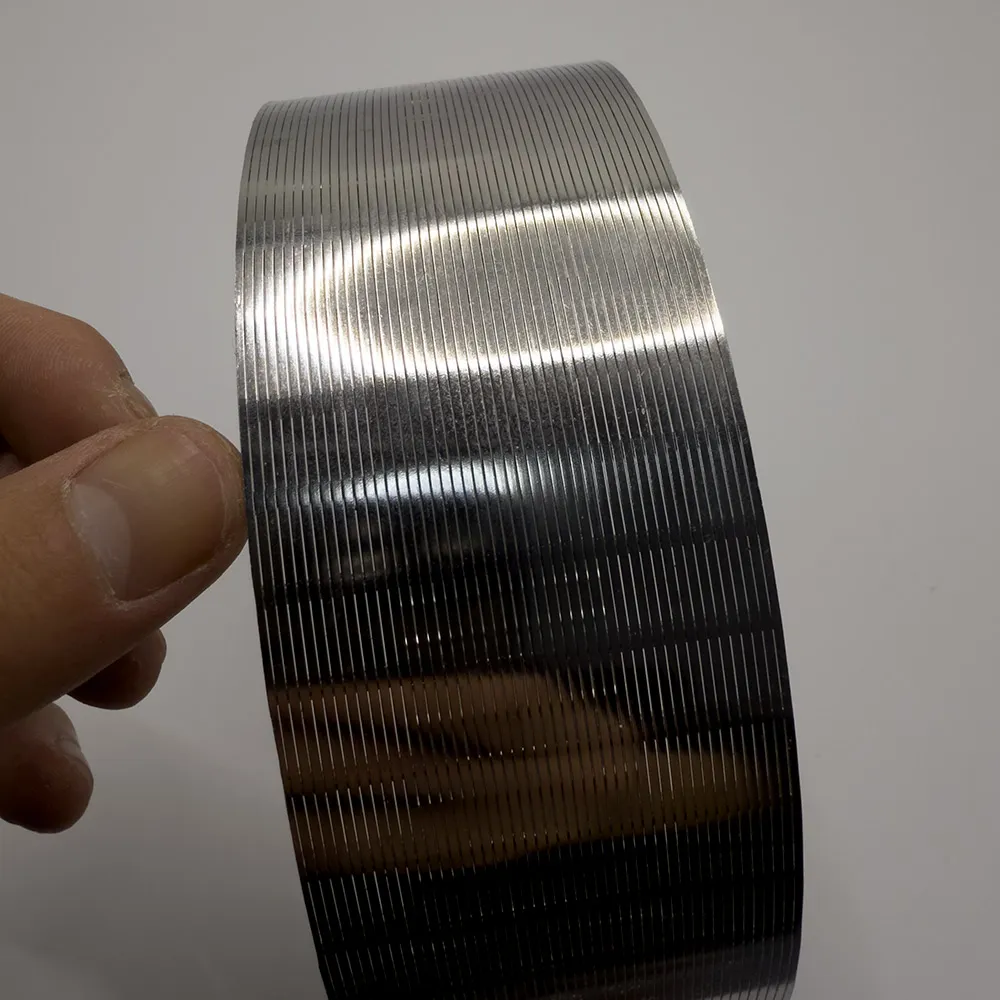

- Introduction to Perforated Alloy Sheets

- Material Composition & Technical Advantages

- Market Analysis: Stainless Steel Perforated Sheet Trends

- Vendor Comparison: Quality vs. Price

- Custom Solutions for Industrial Applications

- Case Studies: Real-World Implementations

- Future Prospects of Perforated Metal Sheets

(perforated alloy sheet)

Understanding Perforated Alloy Sheet Fundamentals

Perforated alloy sheets are engineered for precision, combining durability with functional design. These sheets, typically made from stainless steel, aluminum, or specialized alloys, feature uniform hole patterns that enhance airflow, filtration, and structural efficiency. Industries such as aerospace, construction, and automotive rely on perforated metal sheets for their lightweight yet robust properties. For instance, SS 304 perforated sheets account for 42% of industrial applications due to their corrosion resistance and tensile strength up to 515 MPa.

Material Composition & Technical Advantages

Stainless steel perforated sheets dominate the market, with grades like 304 and 316L offering distinct benefits. SS 304 provides a cost-effective solution with 18% chromium and 8% nickel, while SS 316L includes 2.5% molybdenum for enhanced chloride resistance. Key technical advantages include:

- Thermal stability between -200°C to 800°C

- Load-bearing capacity up to 3,000 kg/m²

- Customizable aperture sizes (0.5mm–20mm)

Market Analysis: Stainless Steel Perforated Sheet Trends

The global perforated metal market is projected to grow at 6.7% CAGR through 2030, driven by infrastructure development. Regional pricing variations for SS 304 sheets reflect raw material costs:

| Region | Price per m² (USD) | Lead Time |

|---|

| North America | 85–110 | 2–3 weeks |

| Europe | 90–120 | 3–4 weeks |

| Asia-Pacific | 65–95 | 1–2 weeks |

Vendor Comparison: Quality vs. Price

Top manufacturers differentiate through certifications and production capabilities:

| Vendor | Material Range | ISO Certification | Minimum Order |

|---|

| Metaltex | SS 304/316, Aluminum | 9001:2015 | 50 m² |

| PerfAlloy Inc. | Specialty Alloys | 14001:2015 | 20 m² |

| SteelMesh Co. | Carbon Steel, SS 430 | N/A | 100 m² |

Custom Solutions for Industrial Applications

Advanced laser-cutting technology enables complex geometries with ±0.1mm tolerance. Recent projects include hexagonal-pattern sheets for architectural facades (35% open area) and micro-perforations (0.8mm diameter) for acoustic panels achieving 28dB NRC ratings.

Case Studies: Real-World Implementations

A chemical plant reduced maintenance costs by 60% after switching to 316L perforated sheets in their filtration systems. In automotive manufacturing, customized aluminum perforated sheets improved heat dissipation by 40% in EV battery housings.

Future Prospects of Perforated Metal Sheet Technology

As sustainability demands increase, perforated alloy sheet

s are evolving with recycled-content options (up to 85% post-industrial scrap). Emerging applications in renewable energy systems and smart architecture ensure continued relevance. Manufacturers investing in AI-driven pattern optimization report 22% faster production cycles and 15% material savings.

(perforated alloy sheet)

FAQS on perforated alloy sheet

Q: What are the common applications of perforated alloy sheets?

A: Perforated alloy sheets are widely used in architectural design, automotive grilles, filtration systems, and industrial machinery due to their durability, airflow control, and aesthetic appeal.

Q: How does a stainless steel perforated sheet differ from other perforated metal sheets?

A: Stainless steel perforated sheets, like SS 304, offer superior corrosion resistance and strength compared to standard alloy sheets, making them ideal for harsh environments or food-grade applications.

Q: What factors influence the SS 304 perforated sheet price?

A: The price depends on sheet thickness, hole pattern complexity, material grade, and order volume. Market demand and supplier pricing strategies also play a role.

Q: Can perforated alloy sheets be customized for specific projects?

A: Yes, customization options include varying hole shapes (round, square, slot), sizes, spacing, and sheet dimensions to meet structural or design requirements.

Q: How do I maintain a perforated metal sheet for longevity?

A: Regular cleaning with mild detergents, avoiding abrasive tools, and applying protective coatings (e.g., galvanization) can prevent corrosion and extend the sheet’s lifespan.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)