- Overview of Perforated Aluminium Mesh and Its Industrial Relevance

- Technical Advantages Over Competing Materials

- Market Comparison: Leading Manufacturers and Product Specifications

- Customization Options for Diverse Applications

- Case Studies: Real-World Implementations

- Environmental and Cost Efficiency Metrics

- Future Trends in Perforated Aluminium Mesh Utilization

(perforated aluminium mesh)

Understanding Perforated Aluminium Mesh and Its Industrial Relevance

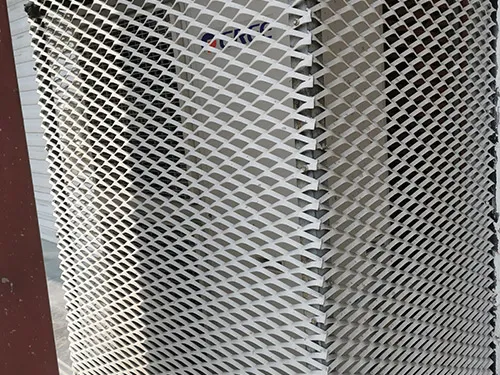

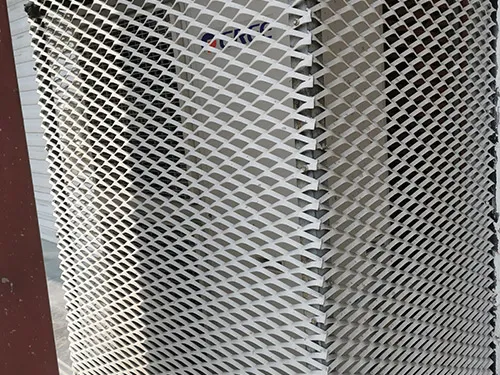

Perforated aluminium mesh is a versatile material engineered for precision and durability. Composed of high-grade aluminium alloys, it undergoes advanced stamping or laser-cutting processes to create uniform apertures. These perforations enhance airflow, light diffusion, and structural flexibility, making it indispensable in architecture, automotive, and filtration industries. According to a 2023 market report, global demand for aluminium perforated metal sheet mesh grew by 8.7% annually, driven by its recyclability and adaptability to harsh environments.

Technical Advantages Over Competing Materials

Aluminium’s inherent properties—lightweight composition (2.7 g/cm³ density), corrosion resistance, and tensile strength (up to 400 MPa)—outperform steel and polymers. For instance, perforated aluminium panels reduce structural weight by 45–60% compared to stainless steel equivalents while maintaining load-bearing capacities. Additionally, anodized or powder-coated finishes extend lifespan by 15–20 years, even in coastal or high-humidity zones.

Market Comparison: Leading Manufacturers and Product Specifications

| Manufacturer |

Hole Diameter Range (mm) |

Sheet Thickness (mm) |

Price per m² (USD) |

Lead Time (Days) |

| Company A |

1.5–10 |

0.5–6 |

28–75 |

7–14 |

| Company B |

2–12 |

0.8–8 |

32–90 |

10–21 |

| Company C |

1–15 |

0.3–5 |

25–68 |

5–12 |

Customization Options for Diverse Applications

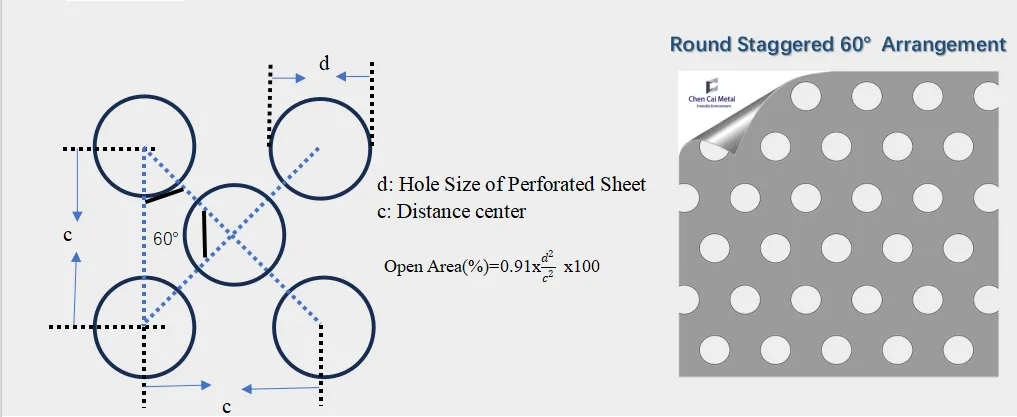

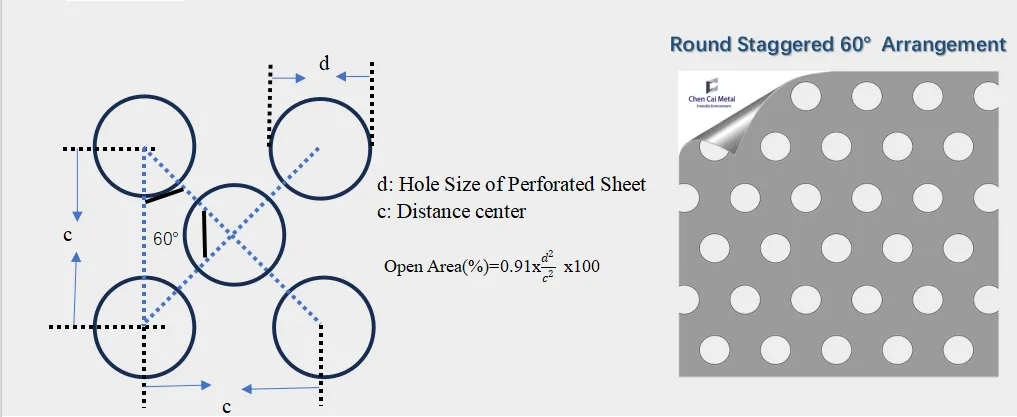

Tailored solutions include hexagonal, round, or square perforations, with aperture sizes ranging from 0.5 mm to 25 mm. Manufacturers offer bespoke patterns for acoustic damping (NRC 0.6–0.9) or solar shading (up to 70% UV blockage). For example, a recent project utilized perforated aluminium mesh

with 3 mm micro-perforations to achieve 92% airflow efficiency in HVAC systems, reducing energy consumption by 18%.

Case Studies: Real-World Implementations

In 2022, a commercial complex in Dubai integrated aluminium perforated panels into its façade, covering 12,000 m². The design reduced solar heat gain by 34%, lowering annual cooling costs by $220,000. Similarly, an automotive manufacturer adopted 2 mm perforated sheets for battery casings, achieving a 27% weight reduction and enhancing thermal management.

Environmental and Cost Efficiency Metrics

Recyclability is a key benefit—98% of aluminium scrap can be reprocessed without quality loss. Lifecycle assessments show that switching to perforated variants cuts material waste by 22% during fabrication. Economically, bulk orders (500+ m²) lower unit costs by 12–15%, with ROI periods under 3 years for industrial installations.

Future Trends in Perforated Aluminium Mesh Utilization

Innovations like AI-driven pattern optimization and nano-coatings are reshaping the aluminium perforated metal sheet mesh landscape. Industry forecasts predict a 11.3% CAGR through 2030, fueled by smart infrastructure and renewable energy projects. As sustainability mandates tighten, this material’s role in circular economies will expand, solidifying its status as a cornerstone of modern engineering.

(perforated aluminium mesh)

FAQS on perforated aluminium mesh

Q: What are the common applications of perforated aluminium mesh?

A: Perforated aluminium mesh is widely used in architectural cladding, ventilation systems, industrial filtration, and decorative panels due to its lightweight, durability, and customizable hole patterns.

Q: How does aluminium perforated metal sheet mesh improve energy efficiency?

A: Its perforations allow airflow and natural light penetration, reducing reliance on artificial lighting and HVAC systems while maintaining structural integrity in buildings.

Q: Can perforated aluminium mesh be customized for specific projects?

A: Yes, hole sizes (1mm to 50mm+), shapes (round, square, hexagonal), and panel dimensions can be tailored to meet architectural, acoustic, or functional requirements.

Q: What makes perforated aluminium panels suitable for outdoor use?

A: Aluminium's natural corrosion resistance, combined with protective coatings like anodizing or powder coating, ensures weather resistance and longevity in harsh environments.

Q: How does perforated aluminium mesh compare to steel alternatives?

A: While both are durable, aluminium offers superior weight-to-strength ratios, rust resistance, and easier installation, though steel may be preferred for ultra-high-load applications.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)