- Understanding Perforated Brass Sheet Metal: Features & Technical Specifications

- Technical Advantages of Brass Perforated Metal Sheets

- Vendor Comparison: Quality, Range, and Pricing

- Customization Solutions for Diverse Industry Needs

- Case Studies: Real-World Decorative & Functional Applications

- Factors Impacting Performance and Longevity

- Why Choose Perforated Brass Sheet Metal for Modern Projects?

(perforated brass sheet metal)

Understanding Perforated Brass Sheet Metal: Features & Technical Specifications

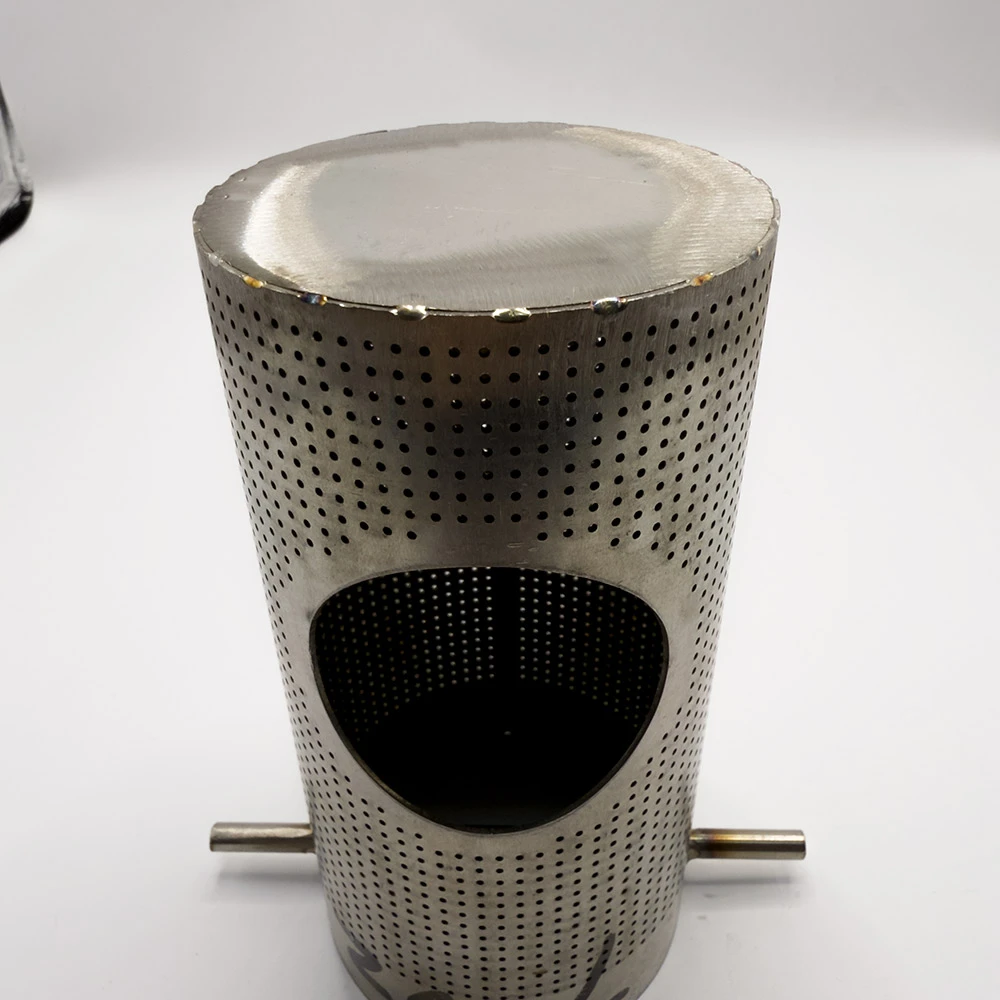

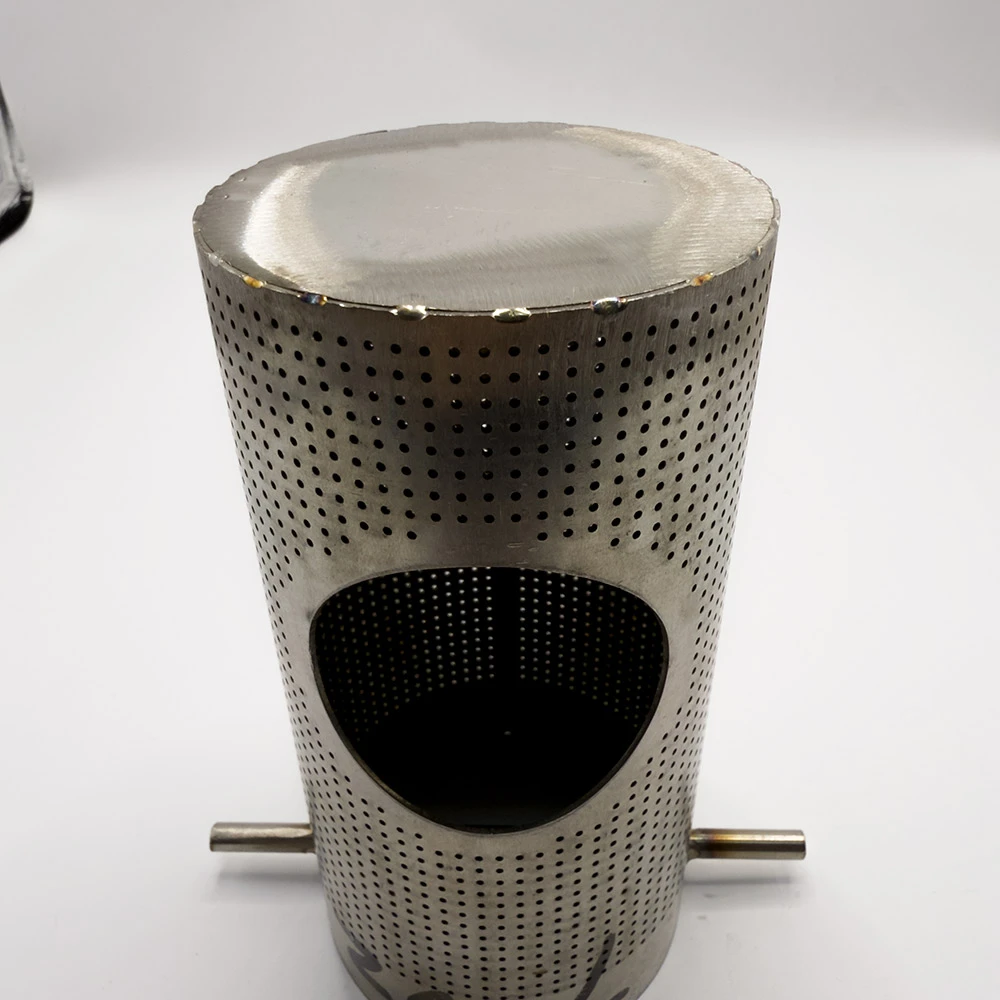

Perforated brass sheet metal stands out in modern engineering and design due to its unique blend of functionality and aesthetics. Manufactured by mechanically punching precise holes into solid brass sheets, this product provides enhanced airflow, visibility, and weight reduction while maintaining the material's natural corrosion resistance and warm, attractive color. Typical properties range from thicknesses of 0.4 to 5 mm, hole diameters from 0.5 to 30 mm, and open areas of 10% to 60%—critical factors for both structural and decorative purposes. In decorative applications, perforated brass offers a reflective luster paired with intricate patterns, significantly boosting visual appeal in architectural and interior design projects.

Technical Advantages of Brass Perforated Metal Sheets

Brass perforated metal sheet provides a range of technical advantages over alternative materials. Its innate corrosion-resistant properties result from an alloy combination primarily composed of copper and zinc, granting excellent durability even in harsh environments. Unlike steel, which can rust, or aluminum, which may easily bend, brass maintains form and finish in both indoor and outdoor installations. The density of brass (approximately 8.44 g/cm³) combined with customizable perforation patterns means users can achieve optimal strength-to-weight ratios. Typically, tensile strength ranges from 350 to 550 MPa, making it suitable for load-bearing screens, grilles, and filtration units. Acoustic performance is another key benefit—precisely distributed perforations help dampen noise in HVAC covers and sound-absorbing partitions.

Vendor Comparison: Quality, Range, and Pricing

Selecting the right supplier for brass perforated metal sheet is crucial. A comparative overview showcases how various manufacturers perform in terms of material grade, pattern options, delivery speed, and pricing.

| Vendor |

Material Grade |

Hole Patterns |

Lead Time (Days) |

Minimum Order (ft²) |

Average Price (USD/ft²) |

| Metals Center USA |

C260, C280 |

Round, Square, Slotted, Custom |

7-10 |

10 |

24.50 |

| BrassPerforate |

C230, C220 |

Round, Hex, Decorative |

4-6 |

5 |

22.80 |

| Perforated Metals Inc. |

C260 |

Round, Custom Geometric |

10-14 |

20 |

25.30 |

| Architectural Metals Group |

C260, Customized Alloys |

Decorative, Laser-cut |

6-9 |

8 |

27.10 |

According to the above data, BrassPerforate offers the best turnaround and pricing for small to mid-sized decorative projects, while Architectural Metals Group excels in custom, high-end decorative solutions. Buyers should weigh quality certifications (ISO 9001, RoHS) and flexible order quantities relative to their project scale.

Customization Solutions for Diverse Industry Needs

Customization sets decorative perforated brass sheet apart as a highly adaptable solution. Modern fabrication technologies enable laser-cutting, CNC punching, and waterjet methods to create almost any perforation pattern—stars, grids, waves, company logos, or intricate motifs. Industries such as architecture, automotive, marine, HVAC, and retail demand unique geometries or branding elements. Surface treatments, including powder coating, mirror polishing, or patination, allow further differentiation for visual or functional requirements. Custom sheet sizes, thicknesses, margins, and open area ratios facilitate use in curved facades, sculptural dividers, lighting fixtures, and even specialized acoustic baffles. With batch and just-in-time production capacities, suppliers are able to meet exacting standards set by architects and engineers alike.

Case Studies: Real-World Decorative & Functional Applications

Decorative perforated brass sheet is widely leveraged across various sectors. Some notable examples include:

- Architectural Facades: In Munich, the Rathaus Gallery utilized over 1,500 m² of triangular-perforation sheets to create a sun-shading skin, reducing solar heat gain by 18% and enhancing interior daylight diffusion.

- Retail Displays: High-end flagship stores across London use custom motif decorative perforated brass sheet to create illuminated backdrops. In one installation, bespoke designs increased foot traffic by 27% due to the distinctive visual appeal.

- Filtration Systems: In the chemical processing industry, precision-perforated brass ensures fine debris separation down to 0.8 mm particle size, maintaining liquid flow rates exceeding 6500 L/hr over sustained periods.

- Acoustic Ceiling Panels: A music auditorium in Tokyo achieved a 22% reduction in reverberation time by installing hex-patterned 3 mm-thick brass panels with 40% open area.

These cases highlight the versatility of brass perforated metal sheet, fitting both functional and aesthetic roles with measurable benefits.

Factors Impacting Performance and Longevity

Multiple variables determine the efficacy and lifespan of a brass perforated sheet metal product. The choice of alloy (C260 most common, but C220 for higher ductility), perforation size and distribution, sheet thickness, and finishing techniques all play crucial roles. Environmental factors like humidity, airborne pollutants, and mechanical stress can accelerate tarnishing or deformation if the alloy or protective coatings are inadequate. Edge finishing and deburring methods impact not only aesthetics but also safety for touch applications in public spaces. Long-term studies report that architectural-grade C260 brass sheets, when properly lacquered, maintain ≥90% of their original luster and strength after 20 years in urban conditions.

Why Choose Perforated Brass Sheet Metal for Modern Projects?

The strategic choice of perforated brass sheet metal

for emerging commercial, architectural, and industrial projects rests on its fusion of distinctive beauty, precision engineering, and enduring value. With a global rise in demand for sustainable and visually striking materials, brass outperforms less noble metals regarding both corrosion resistance and ease of maintenance. Leading architects and product designers consistently specify decorative perforated brass sheet for its ability to meet custom branding, lighting, and environmental goals. Whether aiming for rapid prototyping or large-scale installations, this material provides an unmatched balance of customization capacity, proven durability, and return on investment. Its adoption in projects that prioritize not just form and function, but also long-term operational efficiency and user experience, is expected to increase by 14% annually through 2028, according to market reports.

(perforated brass sheet metal)

FAQS on perforated brass sheet metal

Q: What is perforated brass sheet metal?

A: Perforated brass sheet metal is a brass sheet that's been punched or stamped with holes or patterns. It is commonly used for architectural, decorative, and filtration purposes. Its attractive golden color adds aesthetic appeal.

Q: What are the common uses for brass perforated metal sheets?

A: Brass perforated metal sheets are used in decorative panels, ventilation, acoustic panels, and filter screens. They're popular in interior design, furniture, and industrial applications. Their corrosion resistance and beauty make them versatile.

Q: How is decorative perforated brass sheet different from regular perforated brass sheets?

A: Decorative perforated brass sheets feature custom patterns, shapes, or finishes to enhance visual appeal. They're often used in interior design, wall cladding, or furniture. Regular perforated sheets focus mainly on function, such as ventilation or filtration.

Q: Can perforated brass sheet metal be custom ordered in different patterns and thicknesses?

A: Yes, most suppliers offer custom perforation patterns, hole sizes, and sheet thicknesses based on your requirements. This allows the brass sheet to suit your specific project needs. Custom finishes are also available for decorative purposes.

Q: What are the main advantages of using brass perforated metal sheet?

A: Brass perforated sheets are durable, resist corrosion, and offer an eye-catching golden finish. They provide both functionality (ventilation, filtration) and decorative value. Their versatility makes them suitable for many applications.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)