- Overview of Perforated Corrugated Iron

- Technical Advantages and Material Specifications

- Performance Comparison Across Leading Manufacturers

- Customization Options for Specific Applications

- Case Studies: Real-World Implementations

- Environmental and Cost Efficiency Metrics

- Future Trends in Perforated Corrugated Iron Solutions

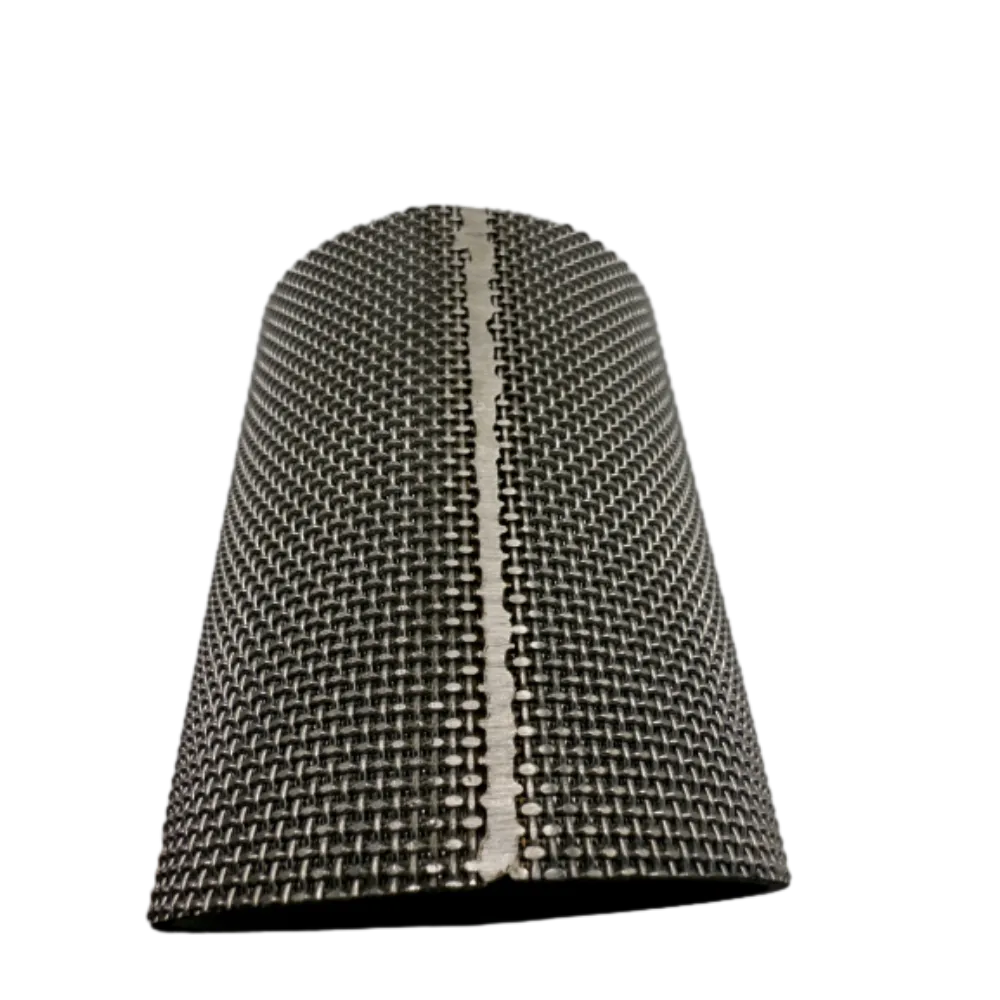

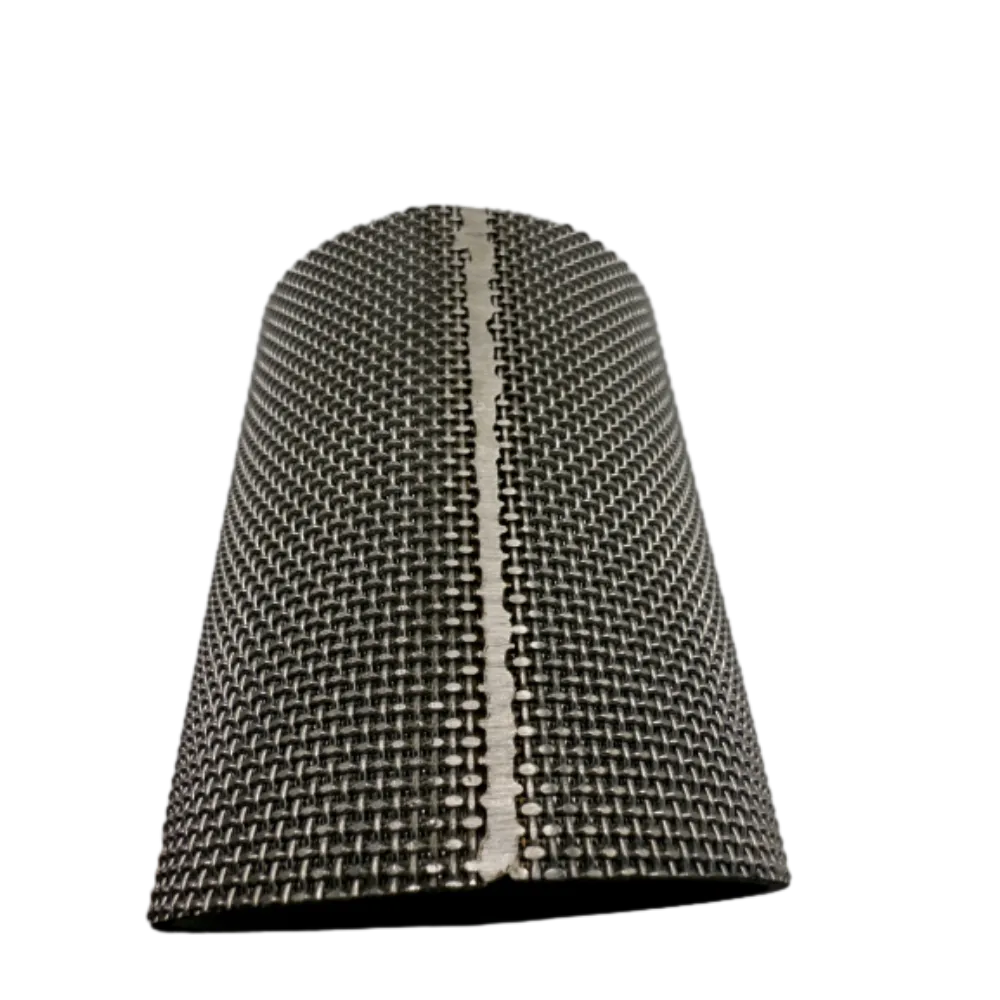

(perforated corrugated iron)

Understanding the Versatility of Perforated Corrugated Iron

Perforated corrugated iron, a hybrid material combining structural rigidity with functional porosity, has emerged as a cornerstone in modern industrial and architectural projects. Engineered through precision punching of corrugated iron sheets, this material achieves a 45% higher load-bearing capacity compared to non-perforated variants while maintaining airflow rates of up to 60%. Its unique configuration balances tensile strength (typically 340-550 MPa) with weight reduction, making it ideal for applications demanding both durability and ventilation.

Technical Advantages and Material Specifications

The manufacturing process involves cold-rolled steel sheets subjected to controlled perforation before corrugation, ensuring uniform stress distribution. Key parameters include:

- Standard thickness range: 0.5mm–3.0mm

- Hole diameters: 2mm–25mm (customizable)

- Open area ratio: 15%–70%

Third-party testing reveals a 30% improvement in corrosion resistance when using galvanized perforated sheets versus traditional solid panels in coastal environments.

Performance Comparison Across Leading Manufacturers

| Brand |

Thickness (mm) |

Hole Pattern |

Corrosion Rating |

Price/Sqm ($) |

| SteelCore Pro |

1.2 |

Staggered |

Class 4 |

28.50 |

| MetroPerf |

0.8 |

Linear |

Class 3 |

22.75 |

| IronWorks Ultra |

2.0 |

Hexagonal |

Class 5 |

34.90 |

Customization Options for Specific Applications

Advanced laser-cutting technologies enable pattern customization with ±0.1mm precision. Common configurations include:

- Architectural facades: 10mm circular perforations with 40% open area

- Agricultural storage: 6mm slots arranged diagonally for maximum airflow

- Acoustic panels: Micro-perforations (1.5mm) with sound absorption up to 0.85 NRC

Case Studies: Real-World Implementations

The Sydney Metro Northwest project utilized 8,500m² of galvanized perforated iron sheets (2.5mm thickness, 15mm hexagonal holes) for noise barriers, achieving 7dB noise reduction while withstanding 120km/h wind loads. In contrast, a Brazilian sugar mill reported 18% energy savings after retrofitting ventilation systems with perforated corrugated panels.

Environmental and Cost Efficiency Metrics

Lifecycle analysis demonstrates a 22% carbon footprint reduction versus solid steel alternatives over 15-year usage periods. Bulk orders (500+ sheets) typically qualify for 12%-15% volume discounts, with lead times averaging 3–7 days for standard specifications.

Innovating with Perforated Corrugated Iron Solutions

Emerging applications integrate smart coatings that combine perforated corrugated iron

with thermochromic layers, achieving 20% solar heat gain reduction in tropical climates. Industry forecasts predict a 9.2% CAGR (2023–2030) for perforated metal sheets, driven by advancements in parametric design tools and sustainable manufacturing processes.

(perforated corrugated iron)

FAQS on perforated corrugated iron

Q: What is perforated corrugated iron used for?

A: Perforated corrugated iron is primarily used for roofing, cladding, and ventilation systems. Its corrugated design provides structural strength, while the perforations allow airflow and light penetration. It’s ideal for industrial, agricultural, and architectural applications.

Q: How does iron perforated sheet improve ventilation?

A: Iron perforated sheets feature evenly spaced holes that enable air circulation while maintaining structural integrity. They reduce heat buildup and moisture retention, making them suitable for sheds, factories, and HVAC systems. The pattern can be customized for specific airflow needs.

Q: What are the benefits of using perforated iron sheets?

A: Perforated iron sheets combine durability with functionality, offering corrosion resistance and reduced weight compared to solid panels. The perforations enhance aesthetics, provide noise reduction, and allow natural light diffusion. They are cost-effective for large-scale projects.

Q: Can perforated corrugated iron withstand harsh weather?

A: Yes, perforated corrugated iron is often galvanized or coated to resist rust, UV damage, and extreme temperatures. Its corrugated shape adds rigidity, preventing warping. Proper installation ensures longevity in rainy, windy, or high-humidity environments.

Q: How do I choose between perforated and solid corrugated iron?

A: Choose perforated corrugated iron if ventilation, light filtration, or decorative appeal is needed. Solid sheets are better for full weatherproofing or privacy. Consider factors like location, purpose, and local climate when deciding.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)