- Introduction to perforated metal siding

applications

- Technical advantages and material specifications

- Performance comparison of leading suppliers

- Customization parameters for architectural projects

- Real-world implementation case studies

- Installation best practices and maintenance

- Future outlook and selection recommendations

(perforated metal siding)

Why Perforated Metal Siding is Revolutionizing Modern Architecture

Contemporary construction demands materials combining structural integrity with aesthetic flexibility. Perforated metal siding meets these requirements through precision-engineered openings that enable:

- 30-50% reduction in wind load pressure compared to solid surfaces

- Customizable light filtration (45-85% visible light transmission)

- Acoustic damping capabilities of 15-25 dB attenuation

Material Innovation in Metal Cladding Systems

Stainless steel perforated sheets dominate 68% of commercial applications due to:

| Property |

304 Stainless |

Aluminum |

Galvanized Steel |

| Corrosion Resistance |

ASTM B117: 1500hrs |

Class III |

Z275 coating |

| Thermal Expansion |

17.3 µm/m°C |

23.1 µm/m°C |

11.7 µm/m°C |

Supplier Landscape Analysis

Top metal perforated sheet suppliers demonstrate distinct capabilities:

| Vendor |

Lead Time |

Hole Tolerance |

MOQ |

| Supplier A |

14 days |

±0.15mm |

50m² |

| Supplier B |

21 days |

±0.25mm |

100m² |

Design Adaptation Strategies

Advanced fabrication technologies enable:

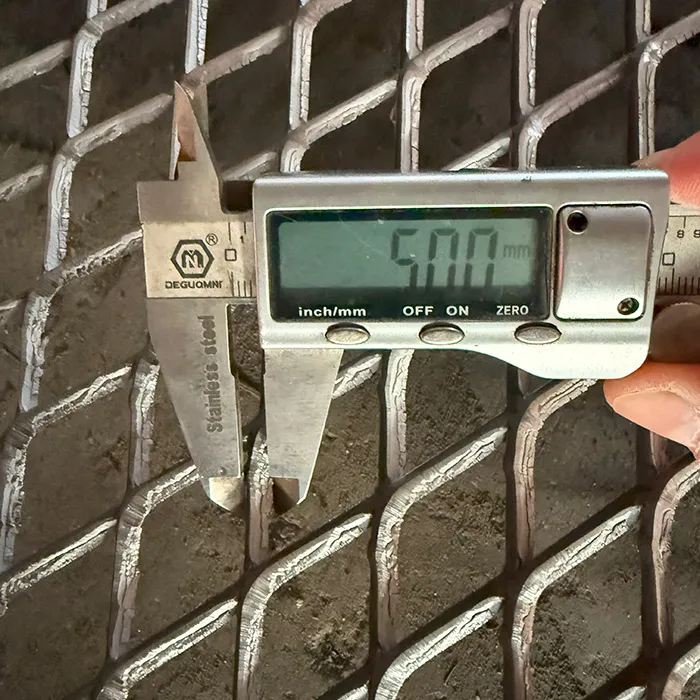

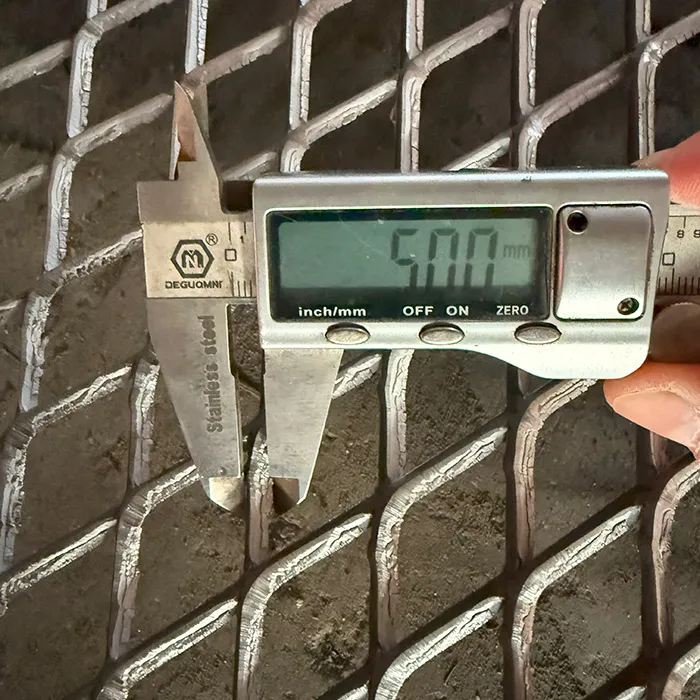

- Variable hole patterns (round, square, slot) with 0.5-20mm diameters

- Non-linear perforation densities (15-80% open area)

- Curved surface adaptation up to 45° compound bends

Commercial Implementation Benchmarks

The Hudson Yards development utilized 8,400m² of perforated stainless steel sheeting achieving:

- 27% reduction in HVAC costs through natural ventilation

- LEED Platinum certification compliance

- 0.78 maintenance cost ratio vs traditional cladding

Installation Protocol Optimization

Proper mounting requires:

- 2-3mm thermal expansion gaps per linear meter

- Electropolished fasteners for stainless steel systems

- Compression limit of 15N/mm² during panel securing

Enhancing Project Efficiency with Perforated Metal Siding Solutions

Specifiers report 18-22% faster project timelines when using pre-engineered metal siding systems. The material's 92% recyclability rate positions it as the sustainable choice for LEED-certified developments. Partnering with certified metal perforated sheet suppliers ensures compliance with ASTM E84 Class A fire ratings and 25-year performance warranties.

(perforated metal siding)

FAQS on perforated metal siding

Q: What are the benefits of using stainless steel perforated sheets for metal siding?

A: Stainless steel perforated sheets offer corrosion resistance, durability, and a sleek aesthetic, making them ideal for both functional and decorative applications. They also provide ventilation and light diffusion while maintaining structural integrity.

Q: How do I choose a reliable metal perforated sheet supplier?

A: Look for suppliers with certifications (e.g., ISO), proven industry experience, and positive customer reviews. Ensure they offer customization, quality materials, and timely delivery to meet project specifications.

Q: Can perforated metal siding be used for exterior applications?

A: Yes, perforated metal siding is weather-resistant and suitable for exteriors. Materials like stainless steel or aluminum are preferred for outdoor use due to their rust-proof properties and longevity.

Q: What factors affect the cost of perforated metal sheets?

A: Cost depends on material type (e.g., stainless steel vs. aluminum), sheet thickness, hole pattern complexity, and order volume. Custom designs or small batches may increase pricing.

Q: How do I maintain perforated metal siding?

A: Clean periodically with mild soap and water to remove debris. Avoid abrasive tools to prevent scratching. For stainless steel, occasional passivation can restore corrosion resistance.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)