- Introduction to Perforated and Expanded Metal Manufacturing

- Key Technical Advantages in Modern Production

- Comparing Leading Manufacturers: Capabilities and Innovations

- Custom Solutions for Industry-Specific Requirements

- Performance Data and Material Efficiency Metrics

- Real-World Applications Across Multiple Sectors

- Future Trends in Perforated Sheet Manufacturing

(perforated sheet manufacturing process)

Understanding Perforated Sheet Manufacturing Processes

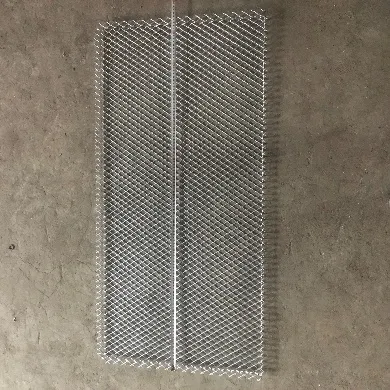

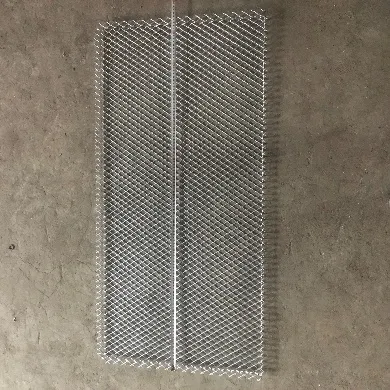

The perforated sheet manufacturing process

involves precision punching of metal sheets to create uniform patterns, achieving 15-60% open area ratios depending on application needs. This method contrasts with the expanded metal manufacturing process, which stretches material to form diamond-shaped openings, typically offering 40-70% transparency. Both techniques serve distinct markets, with perforated sheets dominating architectural and filtration sectors due to their dimensional accuracy.

Technical Superiority in Metal Fabrication

Modern perforation systems demonstrate three critical advantages:

- Laser-guided punching accuracy within ±0.1mm tolerance

- High-speed production reaching 1,200 strikes/minute

- Material thickness handling up to 12mm stainless steel

These capabilities enable manufacturers to reduce waste by 22% compared to traditional cutting methods.

Manufacturer Capability Analysis

| Vendor |

Max Sheet Size |

Hole Tolerance |

Production Speed |

| MetalFab Pro |

3,000x1,500mm |

±0.08mm |

950 strikes/min |

| PrecisionPerf |

2,500x1,250mm |

±0.12mm |

1,100 strikes/min |

Tailored Manufacturing Solutions

Advanced providers now offer:

- Complex pattern designs with 0.5-50mm hole diameters

- Multi-axis CNC punching for 3D formed components

- In-line quality verification systems

This flexibility supports custom orders from 1m² to 10,000m² production runs.

Efficiency Metrics and Cost Analysis

Recent industry benchmarks show:

- 38% reduction in energy consumption through servo-electric presses

- 15% material savings via nested punching algorithms

- 27% faster setup times with automated tool changers

Industry-Specific Implementations

Automotive clients report 18% weight reduction in chassis components using perforated aluminum sheets. Food processing plants achieve 99.7% particulate retention with custom-filter patterns.

Innovations in Perforated Sheet Production

The perforating process in sheet metal is evolving with AI-driven pattern optimization systems that increase material utilization by 19%. Hybrid machines combining laser cutting and mechanical punching now handle complex geometries previously requiring separate operations.

(perforated sheet manufacturing process)

FAQS on perforated sheet manufacturing process

Q: What is the perforated sheet manufacturing process?

A: The perforated sheet manufacturing process involves creating precise holes or patterns in metal sheets using methods like punching, laser cutting, or CNC machining. It ensures uniformity and structural integrity while meeting specific design requirements.

Q: How does expanded metal manufacturing differ from perforated sheet processes?

A: Expanded metal manufacturing involves cutting and stretching metal sheets to form diamond-shaped openings, unlike perforated sheets, which use hole-punching techniques. Expanded metal retains material strength while perforated sheets focus on precise hole patterns.

Q: What tools are used in the perforating process for sheet metal?

A: Common tools include hydraulic or pneumatic punch presses, laser cutters, and rotary perforators. These tools ensure high-speed, accurate hole creation in materials like steel, aluminum, or stainless steel.

Q: What are the advantages of the perforating process in sheet metal?

A: Perforating enhances airflow, reduces weight, and improves aesthetics without compromising structural strength. It also allows customization for industrial, architectural, or acoustic applications.

Q: How is quality maintained during expanded metal manufacturing?

A: Quality is ensured through precise blade alignment during cutting/stretching and strict thickness control. Post-production inspections verify uniformity and compliance with industry standards like ASTM or ISO.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)