- Introduction to Perforated Steel Panels

- Technical Advantages and Material Attributes

- Industry Benchmarking: Manufacturer Comparison

- Tailored Solutions: Customizing Perforated Steel Panels

- Applications and Successful Case Studies

- Expert Insights and Recommendations

- Conclusion: The Future of Perforated Steel Panels

(perforated steel panels)

Introduction: Perforated Steel Panels Overview

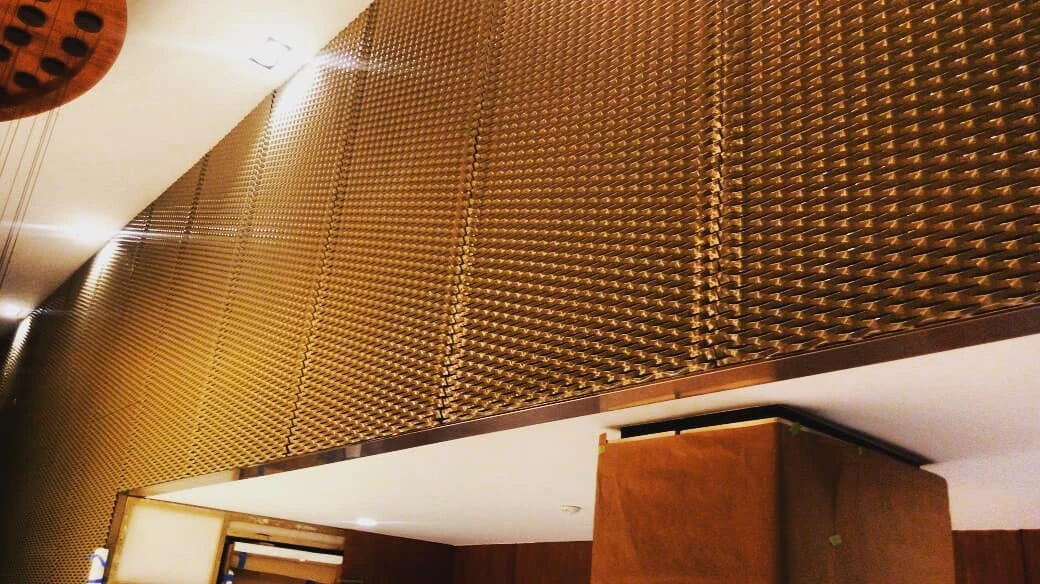

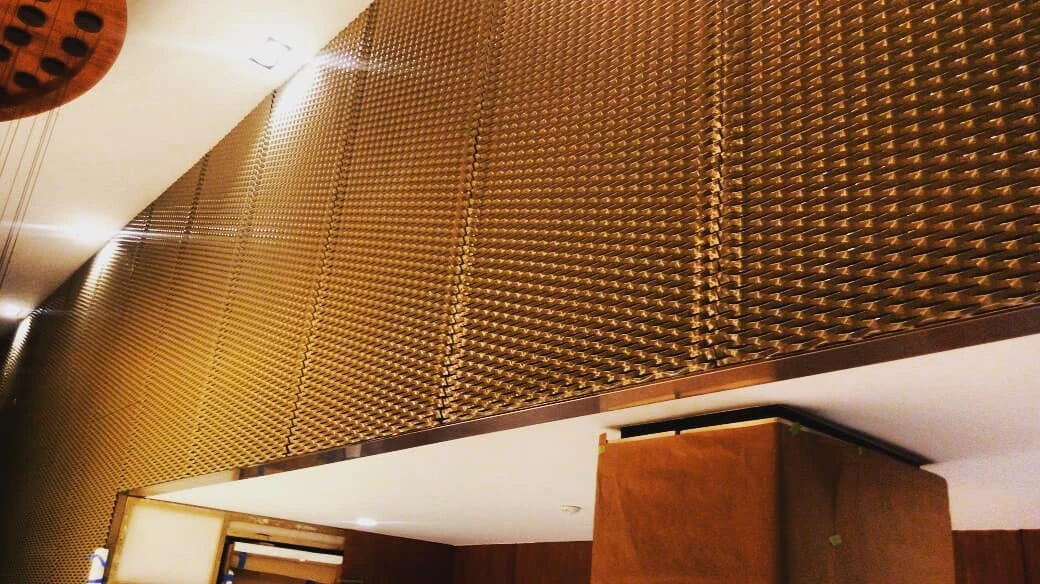

Perforated steel panels, including perforated stainless steel panels and steel perforated panels, have become the essential architectural and industrial elements for modern construction and design. Their integration of strength, aesthetics, and advanced engineering addresses the needs of a wide range of applications, spanning from commercial facades to acoustic shielding and machine protection. With the market for perforated steel panels

projected to exceed USD 8 billion by 2026 and an anticipated compound annual growth rate (CAGR) of 4.3% from 2022, the importance of selecting high-performing, reliable products is more critical than ever. Designers and engineers are increasingly specifying these panels for their performance in ventilation, filtration, and visual appeal, while also meeting the growing sustainability targets of the construction sector.

Technical Advantages & Material Performance

The success of perforated steel panels lies in their finely engineered patterns, precise hole configurations, and the resilience of steel and stainless steel material choices. Perforations can range in diameter from 0.8mm for filtration applications up to 50mm for advanced architectural features. Stainless steel grades (304, 316) ensure superior corrosion resistance, thus making perforated stainless steel panels particularly suitable for harsh environments or food-grade applications. Cold-rolled and hot-rolled steel provide valuable alternatives for non-corrosive environments where structural rigidity is paramount.

The physical properties of these materials have a direct impact on panel durability and function. Typical tensile strengths for stainless steel panels exceed 485 MPa, and the open area ratio can be adjusted—commonly between 10% and 40%—to regulate airflow and light transmission. Moreover, advanced manufacturing techniques achieve tolerances within ±0.15mm, supporting precise installation even on complex curved surfaces. Fire resistance, a key metric in building safety, is inherent in steel, which easily complies with international fire codes and regulations. These panels also provide significant acoustic attenuation, reducing noise levels by up to 30 dB in noisy environments.

Industry Benchmarking: Manufacturer Comparison

Selecting a manufacturer involves analyzing comprehensive data on product variability, quality assurance, and customization capabilities. Below is a comparative table featuring industry-leading perforated steel panel vendors based on critical metrics: maximum panel size, perforation pattern options, material grade availability, lead time, certifications, and average customer rating.

| Manufacturer |

Max Panel Size (mm) |

Pattern Options |

Material Grades |

Lead Time (weeks) |

Certifications |

Customer Rating (1-5) |

| SteelMesh Solutions |

2000 x 6000 |

Round, square, slit, custom |

304, 316, Mild Steel |

3-4 |

ISO 9001, ASTM |

4.8 |

| PerfoMetals Inc. |

1500 x 4000 |

Round, hex, slot |

304, 316, 201 |

2-3 |

ISO 14001 |

4.6 |

| UrbanGrid Panels |

1200 x 3000 |

Decorative, round |

Mild Steel, Alum. |

2 |

UL Listed |

4.9 |

| AlloyPerforate Ltd. |

1800 x 5000 |

Round, custom art |

316, 430, Galvanized |

4 |

CE, ISO 9001 |

4.7 |

The data illustrates the diversity of offerings in panel size, customization, lead time, and certification. SteelMesh Solutions and AlloyPerforate Ltd. provide larger formats suitable for grand projects, whereas UrbanGrid Panels specializes in highly decorative solutions. Decision-makers are encouraged to prioritize capabilities like custom perforation and material grade availability, as these significantly affect final project outcomes.

Tailored Solutions: Customizing Perforated Steel Panels

Customization is fundamental in meeting the specific performance and aesthetic requirements of diverse projects. Leading manufacturers now offer tailored solutions for perforated stainless steel panels, encompassing differential open area ratios, designer patterns, branding integration, and even color finishing through powder coating or anodization. For façade projects, architects often specify a façade coverage of 70-80%, balancing shading, natural light, and external visibility. Recent advances permit digital modeling and laser precision cutting, facilitating the creation of intricate patterns, logos, or text for corporate branding.

To achieve optimal results, a collaborative process between client, designer, and fabricator is key. Project-specific parameters such as wind load resistance, acoustic performance, security needs, and local climate are analyzed, resulting in fully engineered panels tested according to EN 13501-1 or ASTM E84 fire standards. Moreover, modularity and interlocking systems now enable rapid, seamless installation, even on complex or curved surfaces. The integration of green building criteria, including recycled steel content and EPD certification, further elevates the sustainability profile of these panels.

Applications and Successful Case Studies

Perforated steel panels are present in a multitude of applications beyond mere aesthetics. They serve as sunscreens, balustrades, acoustic baffles, ventilation grilles, screening enclosures, security fencing, and HVAC covers. A review of several high-impact projects highlights their unique benefits:

-

Commercial Office Complex, London: Used over 1,200 sqm of perforated stainless steel panels (316 grade, 25% open area). The panels reduced interior solar gain by 18% while retaining unobstructed daylight entry.

-

Urban Rail Station, Singapore: Incorporated custom geometric steel perforated panels for acoustic cladding and visual screening, resulting in a 35 dB reduction in operational noise and improved air circulation.

-

Eco-Housing Project, Berlin: Facade-integrated system using powder-coated panels (60% recycled steel), significantly lowering the project’s embodied carbon. Achieved LEED Gold certification.

-

Industrial Facility, Texas: Heavy-duty galvanized panels deployed as machine guards, delivering fivefold improvement in safety compliance and enabling comprehensive in-situ machine inspection.

These cases demonstrate the high performance, adaptability, and sustainability of perforated steel panels for global projects, setting benchmarks for their role in the built environment.

Expert Insights & Specification Recommendations

Industry professionals recognize that the best outcomes are achieved by early product specification and clear communication on performance goals. For optimal project efficiency and return on investment, prioritize these key considerations:

- Material Selection: Stainless steel grades (especially 316) are recommended for marine or corrosive environments; galvanized and coated mild steel for cost-sensitive indoor or mild outdoor locations.

- Open Area Ratio: Define based on intended ventilation, light transmission, or privacy. Acoustic environments benefit from smaller open areas and denser perforation patterns.

- Panel Geometry: Large, uninterrupted panels minimize joint lines but require careful transport and handling plans.

- Surface Finish: Satin or mirror polish for public-facing installations, powder coating for color matching and enhanced durability.

- Fastening & Support: Specify brackets and support systems compatible with both the panel and the substrate structure.

Engaging manufacturers early can also unlock valuable technical support, from CAD design assistance to mock-ups and impact testing. Their real-time feedback can reduce lead times and prevent costly site modifications.

Conclusion: The Future of Perforated Steel Panels

Perforated steel panels, combining durability, versatility, and visual distinction, stand as a transformative solution for architectural, industrial, and environmental needs. As the construction sector continues to pursue advanced materials and sustainable methods, these panels will increasingly embody both function and form. Whether realized in robust safety screens or expressive façade designs, the future points to greater integration of smart coatings, recycled content, and digital manufacturing, unlocking new potential for both designers and end-users seeking to maximize performance and visual impact.

(perforated steel panels)

FAQS on perforated steel panels

Q: What are perforated steel panels?

A: Perforated steel panels are metal sheets that have been mechanically punched with a pattern of holes. They offer both structural integrity and ventilation. These panels are commonly used for facades, screening, and architectural features.

Q: What are the benefits of choosing perforated stainless steel panels over regular steel?

A: Perforated stainless steel panels resist corrosion and rust, making them ideal for outdoor or humid environments. They also have a sleek, modern aesthetic. Additionally, stainless steel offers long-lasting durability.

Q: Where are steel perforated panels typically used?

A: Steel perforated panels are widely used in building facades, sunscreens, railings, and ventilation grilles. Industries use them for filtration, soundproofing, and decorative elements. Their versatility suits both architectural and industrial applications.

Q: Can perforated steel panels be customized in terms of hole size and pattern?

A: Yes, manufacturers offer customization for the hole size, pattern, and even panel thickness. This flexibility allows you to tailor the panels to your project’s requirements. Common patterns include round, square, and decorative shapes.

Q: Are perforated steel panels easy to maintain?

A: Perforated steel panels are generally low maintenance, especially when made from stainless steel. They require periodic cleaning to remove debris and maintain appearance. Their durability ensures long service life with minimal upkeep.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)