- Factors influencing material pricing

- Technical specifications and quality benchmarks

- Supplier comparison and market analysis

- Custom manufacturing considerations

- Industrial application case studies

- Comparative cost structure breakdown

- Procurement strategies for value optimization

(perforated steel sheet price)

Understanding Perforated Steel Sheet Price Determinants

Material costs for perforated steel sheets fluctuate based on several interconnected market forces. The global price of raw steel constitutes approximately 55-65% of the final product cost, with recent market volatility causing price swings of up to ±18% quarterly. Additional manufacturing variables like sheet thickness (typically ranging from 0.8mm to 12mm) and material grade significantly impact production economics. Thinner gauges below 1.5mm command premium prices due to specialized handling requirements during punching operations.

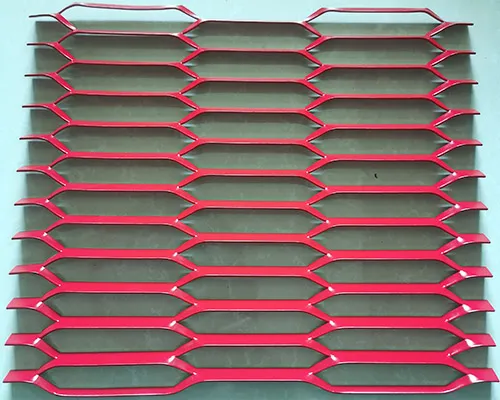

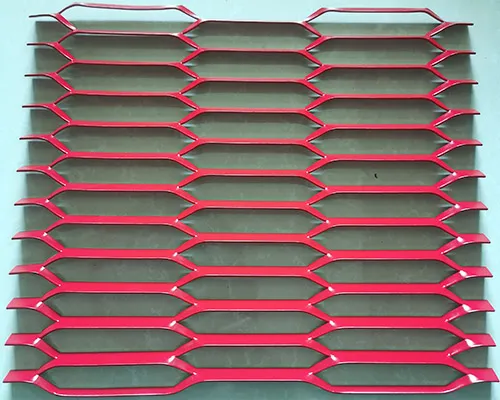

Hole pattern complexity remains another crucial pricing component. Simple round hole patterns typically add 10-15% to base material costs, whereas intricate designs like louvres or slot patterns can increase prices by 25-40% due to extended tooling time and specialized machinery. Production volume substantially influences per-unit pricing, with orders exceeding 50m² generally attracting bulk discounts of 8-12%. Secondary processing factors including flattening, edge treatments, and protective coatings constitute the remaining cost portion.

Technical Specifications Driving Performance

Material selection directly determines functional capabilities across applications. Stainless steel perforated sheets (AISI 304/316) offer superior corrosion resistance with chromium content between 18-20%, ideal for architectural or marine environments. Carbon steel options provide greater structural integrity with tensile strength ratings of 40,000-80,000 psi for industrial flooring applications. Surface treatments like galvanization add protective zinc layers of 35-85 microns, enhancing longevity in corrosive environments.

Hole configuration parameters govern both aesthetic and functional outcomes. Open area percentages vary from 15% for structural applications to 70% for filtration systems, directly impacting permeability. Staggered hole patterns enhance material rigidity versus straight arrangements, while engineered tool clearance prevents metal burring during punching operations. Precision tooling maintains consistent ±0.1mm tolerance for critical applications like pharmaceutical sorting and food processing equipment.

Supplier Quality and Pricing Comparison

| Manufacturer |

Material Grade |

Minimum Order (m²) |

Lead Time (weeks) |

Price Range ($/m²) |

| Precision Perforators |

AISI 304 |

15 |

2-3 |

$47-$89 |

| SteelMesh Solutions |

Mild Steel |

25 |

3-4 |

$28-$65 |

| Architectural Metals |

Aluzinc |

10 |

1-2 |

$56-$124 |

| Industrial Perf Ltd |

AISI 316 |

40 |

4-5 |

$98-$153 |

Customization and Application Engineering

Specialized applications require engineered solutions that affect stainless steel perforated sheet price structures significantly. Architectural projects often require custom profiles with proprietary hole patterns and finishing treatments, increasing costs by 25-60%. Food processing plants mandate specialized certifications including 3.1 mill certificates and ASME BPE compliance, adding administrative overhead.

Technical specifications frequently include material-specific requirements:

- Vibration dampening: Diamond-shaped holes with 65-75% open area

- Acoustic panels: Micro-perforations of 0.5-1.0mm diameter

- Ballistic protection: 4mm thick AR500 steel with hexagonal holes

- Walkway surfaces: Raised diamond patterns with 2.5mm material thickness

Industrial Application Case Studies

Perforated sheets deliver exceptional functionality across sectors. In the Aberdeen Water Treatment facility, stainless steel perforated sheets with 2mm thickness and 20% open area handled 4.5 million liters daily with virtually zero corrosion after five years. Manufacturing environments deploy carbon steel variants for machinery guarding where structural reinforcement and impact resistance reduce workplace injuries by up to 43%.

Architectural applications demonstrate both functional and aesthetic value. The Miami Art Institute facade features 900 square meters of custom-perforated aluminum with interlocking geometric patterns that reduce solar heat gain by 25% while creating dynamic light effects. These applications commonly see price premiums of $75-$125 per square meter for architectural-grade materials with custom finishes.

Cost Structure Analysis

Comprehensive pricing evaluation reveals how material choices affect long-term expenditures. Premium-grade stainless steel perforated sheet price exceeds carbon steel by 100-120% initially, but life-cycle cost analysis shows significant advantages. Stainless steel requires no maintenance over typical 15-year service life, while carbon steel demands annual protective treatments costing approximately $18/m² per year.

Economic factors include:

- Material: 55-70% of total cost

- Tooling: 8-12% (higher for complex patterns)

- Secondary processing: 10-15%

- Shipping: 5-8%

- Certification: 3-7%

Optimizing Stainless Steel Perforated Sheet Price

Strategic sourcing approaches significantly impact perforated steel sheet price

outcomes. Volume consolidation through blanket orders covering multiple projects can secure 10-18% manufacturer discounts. Standard hole patterns reduce tooling costs by 15-25% versus custom designs. Coordinating with metal service centers allows access to remnant materials at 20-35% savings for smaller projects.

Technical specifications should align with functional requirements without over-engineering. For indoor applications without corrosion exposure, powder-coated carbon steel offers 40-50% savings over stainless options while maintaining aesthetics. Implementing modular sizing reduces material waste by 12-18% compared to custom dimensions. Seasonal buying patterns reveal first-quarter pricing historically runs 7-9% lower than peak construction periods.

(perforated steel sheet price)

FAQS on perforated steel sheet price

Q: What factors influence the perforated steel sheet price?

A: The price depends on material grade, sheet thickness, hole pattern, and quantity ordered. Custom designs or smaller orders may cost more per unit. Suppliers also adjust pricing based on market demand and raw material costs.

Q: How does perforated stainless steel sheet price compare to regular steel?

A: Stainless steel perforated sheets are typically 20-50% more expensive due to corrosion resistance and durability. Higher-grade alloys like 304 or 316 stainless steel further increase costs. Prices also vary based on finishing treatments.

Q: Why do stainless steel perforated sheet prices vary between suppliers?

A: Differences arise from manufacturing processes, quality certifications, and logistical expenses. Some suppliers include value-added services like laser cutting in quotes. Always compare specifications, not just pricing, when evaluating offers.

Q: Can I get discounts for bulk perforated steel sheet orders?

A: Most suppliers offer volume discounts for large-scale purchases. Savings increase with standardized hole patterns and sheet sizes. Request a tiered pricing structure for quantities above 100 sheets.

Q: Does sheet thickness significantly affect perforated stainless steel prices?

A: Thicker sheets (e.g., 3mm+) cost more due to material usage and machining time. Thinner sheets (1-2mm) are cheaper but require precise tooling. Always specify thickness tolerance requirements in your RFQ.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)