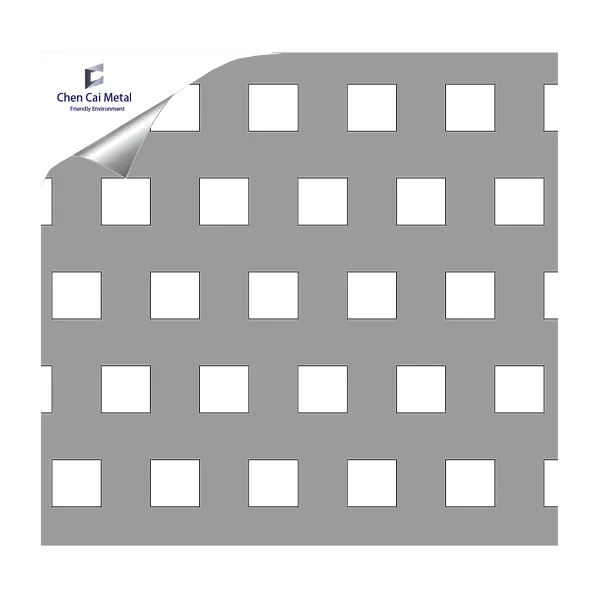

In the realm of advanced material solutions for industrial applications, the square hole perforated sheet stands as a testament to engineering ingenuity, offering unparalleled versatility and performance. This product category, encompassing square hole perforated sheet metal and metal sheet with square holes, is critical across a multitude of sectors, driven by evolving industry trends that demand greater material efficiency, improved flow dynamics, and enhanced structural integrity. Modern industrial landscapes, from architectural design to petrochemical filtration, are increasingly reliant on materials that can withstand harsh operational conditions while contributing to energy conservation and extended service life. The demand for perforated sheet square hole configurations specifically has seen a significant uptick due to their optimal balance of open area, strength, and aesthetic appeal. This growth is underpinned by stringent regulatory requirements for safety and environmental protection, prompting industries to seek materials that meet high standards of corrosion resistance, thermal stability, and mechanical resilience. Our focus on staggered square perforations ensures superior performance in demanding environments, offering a unique blend of attributes that are vital for critical applications. The strategic arrangement of these perforations optimizes fluid and air flow, making them indispensable in processes requiring precise material separation or acoustic dampening. Furthermore, the aesthetic consistency provided by square hole perforated sheet designs makes them a preferred choice for architectural facades and interior design elements, reflecting a trend towards functional beauty in industrial and commercial spaces. This section serves to introduce the foundational importance of this material in contemporary engineering challenges, setting the stage for a deeper dive into its manufacturing intricacies, technical specifications, and diverse applications.

The production of a square hole perforated sheet is a sophisticated process, meticulously engineered to ensure the highest standards of quality and performance. The journey begins with the selection of premium raw materials, typically including stainless steel (grades 304, 316, 316L), carbon steel, galvanized steel, aluminum, brass, or even specialized alloys, chosen based on the intended application's specific environmental and mechanical requirements. Unlike traditional casting or forging, the primary manufacturing process for these sheets involves precision punching or stamping. This method utilizes high-speed presses equipped with custom-designed dies that accurately punch the desired square patterns into the metal sheets. For staggered square perforated sheet, the dies are configured to create a diagonal or offset arrangement of holes, which optimizes the open area and enhances the material's strength-to-weight ratio. Post-perforation, the sheets undergo rigorous finishing processes, which may include leveling, degreasing, and deburring to remove any sharp edges or imperfections. Surface treatments such as powder coating, anodizing, or galvanization are then applied to enhance corrosion resistance, improve durability, and provide aesthetic finishes. Throughout this entire production chain, stringent quality control measures are implemented. Adherence to international standards such as ISO 9001 for quality management and ASTM for material specifications is paramount, ensuring consistency in hole size, pattern accuracy, and material composition. Inspection processes involve visual checks, dimensional measurements using calipers and laser scanners, and material integrity tests to guarantee that each metal sheet with square holes meets the precise technical parameters and client specifications. This meticulous approach ensures a product with an exceptional service life, capable of performing reliably for decades in demanding industrial environments like petrochemical processing, where resistance to corrosive chemicals is critical, or in metallurgy for screening applications. The energy-saving potential of these sheets is also significant; in HVAC systems, for instance, their optimized open area reduces fan energy consumption by allowing unrestricted airflow, while in filtration, they enhance throughput, leading to more efficient operations and reduced energy footprint.

Understanding the technical parameters of a square hole perforated sheet is crucial for effective material selection and optimal application performance. Key specifications define the functionality and suitability of the sheet for various industrial needs. The hole size, measured as the side length of the square aperture, directly impacts the filtration capacity, sound absorption properties, and aesthetic appearance. Pitch refers to the distance from the center of one hole to the center of an adjacent hole, which, in conjunction with hole size, determines the open area percentage—a critical metric representing the proportion of the sheet that is open for flow. A higher open area allows for greater air or liquid flow, while a lower open area enhances structural rigidity and finer filtration. Sheet thickness is another vital parameter, influencing the material's strength, weight, and durability. Thicker sheets offer superior resistance to impact and heavy loads, whereas thinner sheets are lighter and more flexible. The material type (e.g., SS304, SS316, galvanized steel, aluminum) dictates resistance to corrosion, temperature, and specific chemical environments. For instance, Stainless Steel 316L is preferred in highly corrosive chemical processing due to its enhanced molybdenum content. The perforated sheet square hole configuration, particularly in a staggered pattern, provides an optimized balance of strength and open area, preventing premature clogging and ensuring uniform distribution in screening and diffusion applications. Our products consistently meet or exceed industry benchmarks for these parameters, backed by comprehensive test data and strict quality assurance protocols. For example, our 1.5mm thick SS304 sheets with 5mm square holes and an 8mm staggered pitch typically achieve an open area of approximately 35%, ideal for effective screening without compromising structural integrity. This precise engineering ensures that our square hole perforated sheet metal products deliver consistent and reliable performance, contributing to the overall efficiency and longevity of industrial systems.

| Parameter | Common Range/Value | Impact on Performance |

|---|---|---|

| Material | Stainless Steel (304, 316, 316L), Carbon Steel, Galvanized Steel, Aluminum, Brass | Corrosion resistance, strength, cost, weight, weldability. |

| Hole Size (Square Side) | 3mm to 50mm (0.125" to 2") | Filtration accuracy, flow rate, light diffusion, sound absorption. |

| Pitch (Staggered) | 5mm to 75mm (0.2" to 3") | Open area percentage, pattern density, structural stability. |

| Sheet Thickness | 0.5mm to 6mm (24 Gauge to 1/4") | Weight, rigidity, durability, formability. |

| Open Area Percentage | Typically 20% - 60% | Flow efficiency (air/liquid), light transmission, acoustic properties. |

| Sheet Dimensions (Standard) | 1000x2000mm, 1220x2440mm, 1250x2500mm (or custom) | Ease of installation, material waste, project scope. |

The adaptability and robust performance of square hole perforated sheet products position them as indispensable components across a vast array of industries. In the petrochemical sector, these sheets are extensively used in catalyst support grids, filter screens, and column internals due to their excellent resistance to high temperatures and corrosive chemicals, significantly enhancing process efficiency and safety. For the metallurgy industry, particularly in mining and mineral processing, metal sheet with square holes serve as durable screening media for sizing and separating various ore materials, minimizing downtime and maximizing yield. In water supply and drainage systems, they function as robust filtration elements, preventing debris ingress into pumps and pipelines, thereby extending the lifespan of critical infrastructure. Architectural applications leverage the aesthetic appeal and light-diffusing properties of perforated sheet square hole designs for building facades, sunshades, balustrades, and interior ceilings, contributing to both functional ventilation and modern design. The automotive industry employs these sheets in muffler components and engine bay covers for noise reduction and heat dissipation, showcasing their acoustic and thermal management capabilities. Furthermore, in HVAC (Heating, Ventilation, and Air Conditioning) systems, they are vital for air diffusers and grilles, ensuring optimal airflow distribution and acoustic control. The technical advantages offered by our staggered square hole perforated sheet are multifaceted. Their precise hole pattern ensures uniform fluid or air distribution, critical for efficient filtration and ventilation. The inherent rigidity of the perforated metal provides superior structural support compared to mesh or woven materials, allowing for higher load-bearing capacity. Moreover, the open area percentage can be meticulously controlled to balance strength with flow requirements, leading to significant energy savings in systems where unrestricted movement of media is essential. Our commitment to delivering high-performance products is reflected in consistent customer feedback, highlighting enhanced operational efficiency and reduced maintenance needs. A recent case study involving a wastewater treatment plant noted a 15% improvement in filtration efficiency after upgrading to our custom-designed stainless steel square hole perforated sheet filters, directly translating to lower energy consumption and reduced operational costs. This real-world application underscores the tangible benefits and superior performance that our specialized perforated solutions bring to complex industrial challenges.

At the forefront of metal mesh manufacturing, our capabilities extend far beyond standard offerings, embracing comprehensive customization to meet the unique and specific demands of diverse industrial applications. Recognizing that off-the-shelf solutions rarely align perfectly with complex engineering challenges, we specialize in providing tailored square hole perforated sheet designs. This includes a flexible approach to material selection, accommodating everything from standard stainless steel grades to specialized alloys that offer enhanced resistance to extreme temperatures, corrosion, or abrasive wear. Furthermore, we offer extensive customization in terms of hole size, pitch, open area percentage, sheet dimensions, and even specific edge margins to ensure seamless integration into existing or new systems. Our expert engineering team collaborates closely with clients from the initial conceptualization phase through to final production, utilizing advanced CAD/CAM software to simulate performance and optimize designs for maximum efficiency and cost-effectiveness. This collaborative approach ensures that every metal sheet with square holes we produce is precisely calibrated to the operational parameters and environmental conditions of its intended use. Our reputation for authoritative service is built on decades of industry experience, with a service tenure exceeding 20 years in delivering high-quality perforated metal solutions. We pride ourselves on transparent communication, rigorous quality control, and a commitment to continuous improvement, evidenced by our ISO 9001 certification. Our robust supply chain and advanced manufacturing facilities enable us to handle orders of varying scales, from prototype batches to large-volume industrial requirements, with efficient turnaround times. We have cultivated strong partnerships with leading enterprises across the petrochemical, energy, automotive, and construction sectors, consistently earning their trust through reliable product performance and exceptional client support. Our state-of-the-art testing laboratories perform comprehensive material analysis and performance verification, providing detailed reports that underscore the superior quality and compliance of our perforated sheet square hole products with relevant industry standards such as ASTM, ANSI, and local regulatory requirements. This dedication to precision, customization, and trusted partnerships solidifies our position as a leading provider of high-performance perforated metal solutions.

Building trust with our clients is paramount, and a core component of this is providing transparent information and robust support for every square hole perforated sheet solution we offer. We understand that purchasing industrial components requires confidence in product quality, delivery, and after-sales service. To address common inquiries and provide immediate clarity, we have compiled a list of frequently asked questions regarding our staggered square perforated sheet products. Our standard delivery cycle typically ranges from 2 to 4 weeks, depending on order volume, customization requirements, and material availability. However, we also offer expedited services for urgent projects, leveraging our efficient production lines and established logistics networks. Each product is meticulously inspected and packaged to prevent damage during transit, ensuring that it arrives in pristine condition, ready for immediate deployment.

Our commitment to customer support extends beyond initial sales. We provide comprehensive technical assistance, guiding clients through product selection, installation, and maintenance. This proactive engagement ensures that our square hole perforated sheet metal products perform optimally throughout their impressive service life, solidifying long-term partnerships built on trust and mutual success.

The strategic adoption of staggered square perforated sheet technology represents a significant advancement in industrial material solutions, offering a compelling blend of structural integrity, operational efficiency, and aesthetic versatility. From critical filtration in petrochemical facilities to sophisticated architectural applications and precise screening in metallurgy, the inherent benefits of square hole perforated sheet are undeniable. Our unwavering commitment to precision manufacturing, stringent quality control, and client-centric customization ensures that each product not only meets but often exceeds the demanding requirements of modern industrial environments. By providing superior material solutions, we empower industries to achieve greater operational efficiency, enhance safety protocols, and contribute to more sustainable practices.

PREV:

This is the last article