Introduction to Diamond Expanded Metal

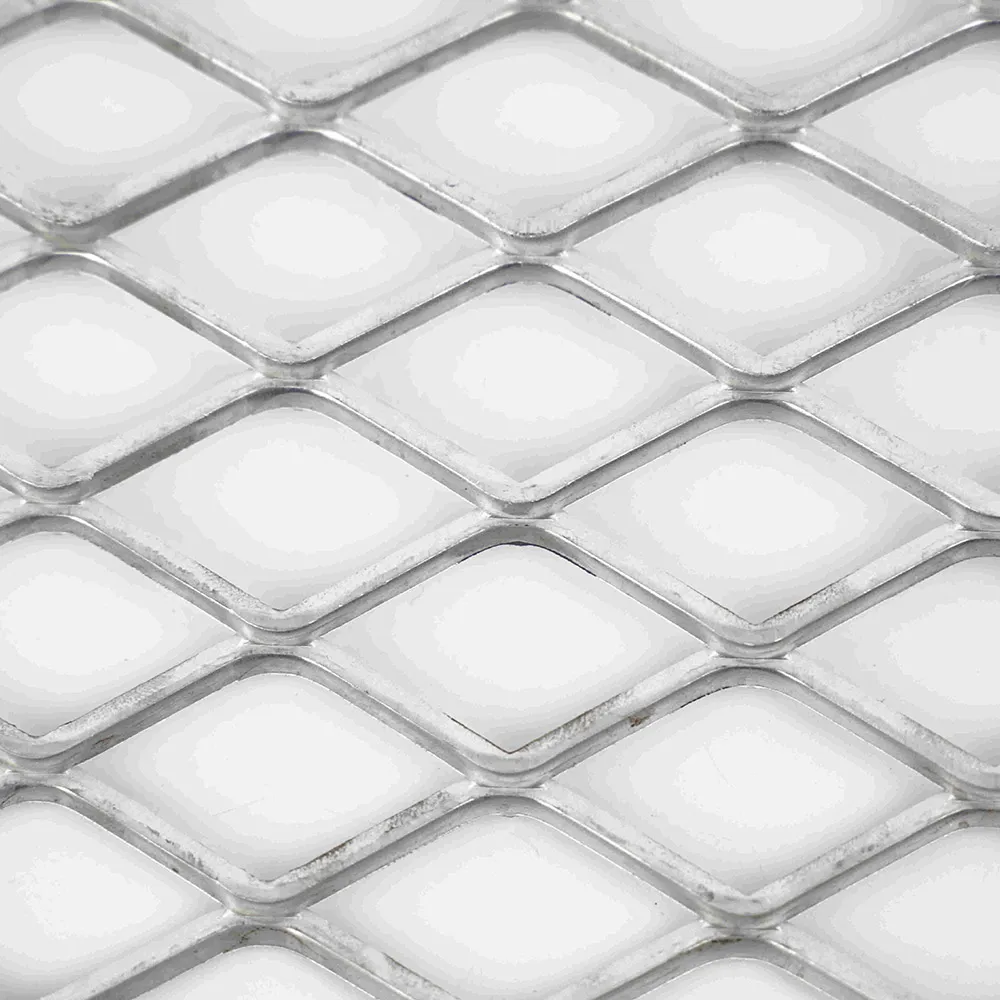

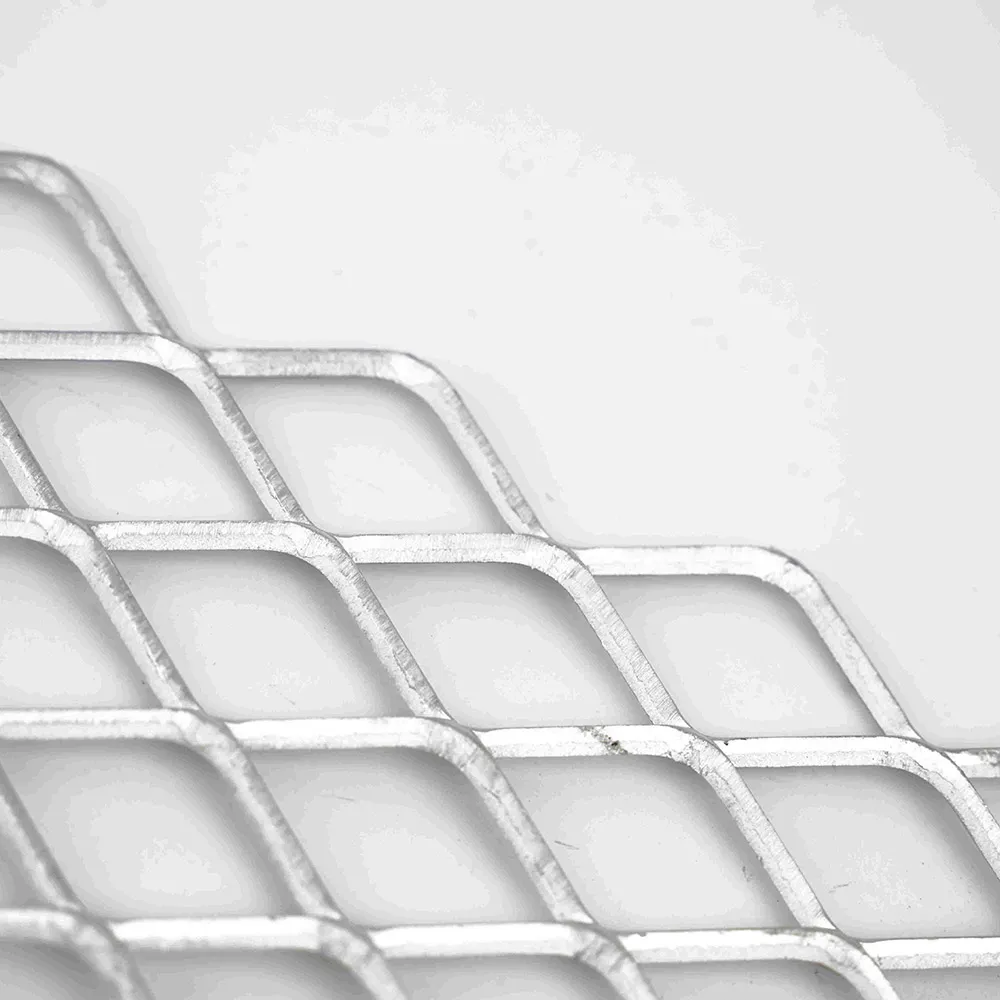

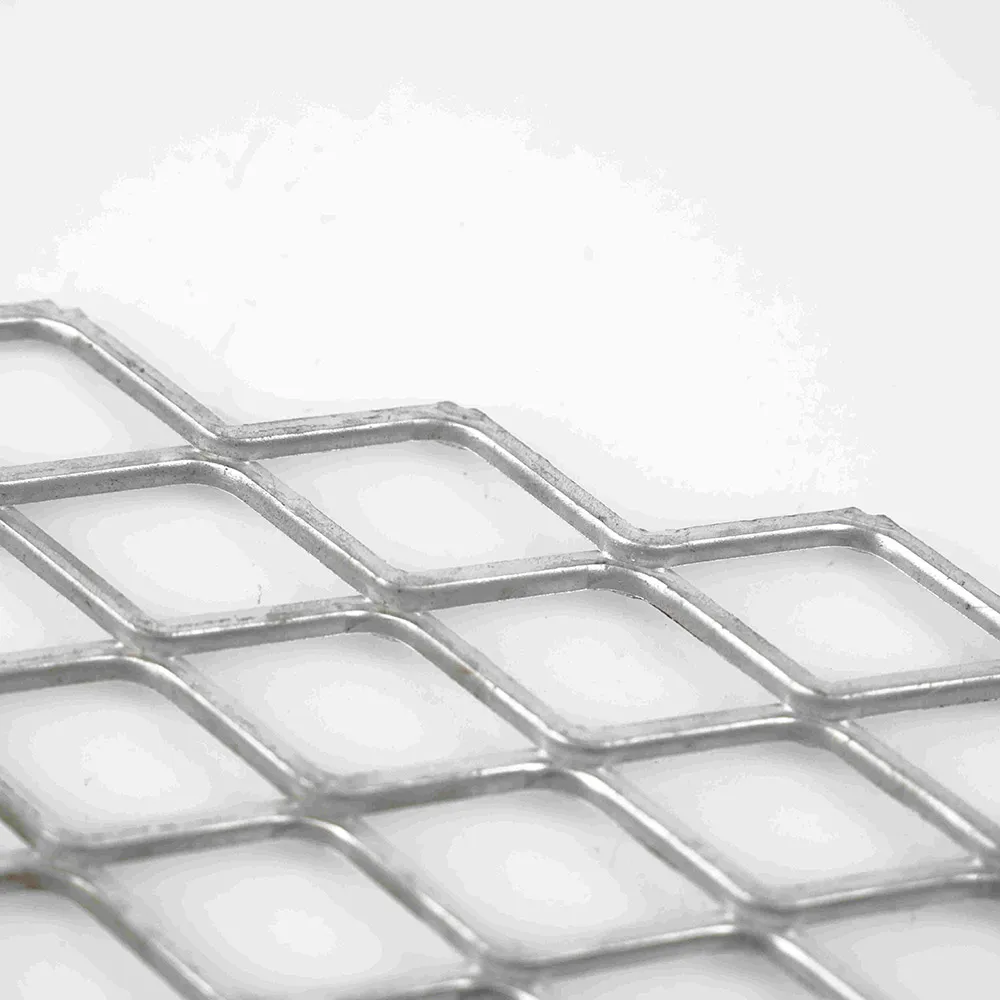

Diamond expanded metal is a versatile engineered material created by simultaneously slitting and stretching metal sheets to form diamond-shaped openings. This distinctive manufacturing process enhances the structural integrity of the base material while significantly reducing weight. The resulting mesh offers exceptional strength-to-weight ratio, ventilation, drainage capabilities, and unique aesthetic qualities not achievable with solid metal sheets.

At Anping Chen Cai Metal Manufacture Co. Ltd., we've been producing premium diamond expanded metal since 2003. Our products stand out for their precise dimensional accuracy, consistent quality, and outstanding performance in demanding environments. We serve clients globally across construction, automotive, filtration, and industrial sectors with our specialized manufacturing expertise.

The Manufacturing Process

Creating diamond expanded metal involves precise engineering and controlled mechanical deformation. Our production begins with raw steel, aluminum, or stainless steel coils which pass through a specialized expanding machine. This equipment features staggered blades that slit the metal in precise alternating patterns while simultaneously stretching it to form the characteristic diamond shapes.

Technical Specifications

The performance characteristics of diamond expanded metal vary according to specific parameters that determine its application suitability. Below is a comprehensive technical specification table comparing different grades of diamond expanded metal:

| Parameter |

Standard Grade |

Heavy Duty |

Flattened |

Aluminum |

Stainless Steel |

| Thickness (mm) |

0.8-3.0 |

3.0-8.0 |

1.2-4.0 |

0.6-3.0 |

0.7-6.0 |

| Mesh Size (mm) |

10x20 to 30x60 |

15x30 to 40x80 |

12x25 to 35x75 |

8x16 to 25x50 |

10x20 to 30x60 |

| Weight Savings |

40-50% |

25-35% |

30-40% |

45-55% |

35-45% |

| Tensile Strength (MPa) |

350-500 |

500-700 |

300-450 |

150-250 |

520-750 |

| Surface Area Increase |

150-250% |

120-180% |

130-200% |

180-300% |

160-230% |

| Corrosion Resistance |

Moderate |

Moderate |

Good |

Excellent |

Superior |

| Typical Applications |

Guards, Filters |

Platforms, Walkways |

Architectural |

Transportation |

Food Processing |

Industry Trends and Technological Advancements

The global market for diamond expanded metal has witnessed consistent growth at 6.8% CAGR from 2020 to 2023, driven by increasing infrastructure development and demand for lightweight yet strong materials. Environmental sustainability has become a key driver, with diamond expanded metal's recyclability and eco-friendly production process aligning with global green building initiatives like LEED certification requirements.

Innovation is transforming the industry. The latest development in diamond expanded metal manufacturing at Chen Cai Metal includes our precision laser-expanded technology. This advanced process allows micron-level accuracy in mesh openings and enables complex pattern designs impossible with traditional methods. Additionally, our proprietary nano-coating treatment enhances corrosion resistance by 300% compared to standard galvanized finishes, significantly extending product lifespan in harsh environments.

Comparative Performance Analysis

Modern architectural and industrial applications increasingly demand materials that offer multi-functional capabilities. The graph above illustrates why diamond expanded metal outperforms alternative materials like perforated metal, woven wire mesh, and sheet metal in critical performance categories. Its exceptional strength-to-weight ratio combined with superior ventilation and drainage capabilities make it the material of choice for applications requiring structural integrity without excessive mass.

Industrial Applications of Diamond Expanded Metal

Architectural and Construction

Diamond expanded metal has revolutionized architectural design possibilities. Architects value it for creating visually striking facades that manipulate light and shadow patterns. Its durability in structural applications includes stair treads, security screens, and balcony enclosures where it provides both safety and aesthetic appeal. The Shanghai Innovation Center utilized over 8,000m² of our custom-designed diamond expanded metal for its award-winning facade system.

Industrial Machinery and Safety

Industrial applications leverage diamond expanded metal's strength and rigidity. It serves as machine guards that provide visibility while protecting personnel from moving parts. In platforms and walkways, the slip-resistant surface ensures worker safety while its open design prevents liquid accumulation. Industrial filtration systems benefit from the precision openings and durability of diamond expanded metal in demanding environments.

Transportation Infrastructure

Transportation sectors use diamond expanded metal for truck trailer floors, railcar components, and noise barriers along highways. Its high strength with reduced weight translates to significant fuel savings - our studies show a 30% weight reduction in trailer flooring equates to 7.5% annual fuel savings for logistics fleets. The Beijing-Daxing International Airport utilized our material for its acoustic barrier system.

Professional FAQ: Diamond Expanded Metal

Q1: What materials can be used to manufacture Diamond Expanded Metal?

The most common materials include mild steel (with various finishes), stainless steel grades (304, 316), aluminum alloys, and specialized alloys like Corten steel. Material selection depends on environmental factors, structural requirements, and corrosion resistance needs.

Q2: How is Diamond Expanded Metal measured and specified?

Key specifications include sheet thickness, strand width, bond length, and opening dimensions (LWD - Long Way of Diamond, SWD - Short Way of Diamond). Industry standards like ASTM F1264 and BS 2926 govern measurements to ensure uniformity across manufacturers.

Q3: What are the weight calculation methods for Diamond Expanded Metal?

Weight is calculated using the formula: (Thickness x Width x Length x Density) / (1 + Opening Percentage). Industry standard CAD systems automatically calculate weight based on pattern geometry, providing precise projections for structural applications.

Q4: How does the manufacturing process affect structural properties?

The expansion process work-hardens the material, increasing tensile strength by 15-25% compared to the original coil stock. However, the directional nature of expansion creates different mechanical properties along the length versus the width of the material.

Q5: What protective finishes extend product lifespan?

Common protective treatments include hot-dip galvanizing (zinc coating), powder coating, PVC coating, and specialized polymer finishes. For harsh environments, duplex coating systems combine galvanizing with powder coating to achieve protection exceeding 50 years.

Q6: What welding techniques are recommended for installation?

Standard fabrication employs MIG welding, spot welding, or specialized clip systems. Thin gauges require careful heat control to prevent distortion. Proper welding techniques should maintain at least 50% of the mesh opening for ventilation and drainage integrity.

Q7: How does flattened expanded metal differ from standard?

Flattened expanded metal undergoes an additional cold-rolling process after expansion, creating a smooth surface ideal for architectural applications. While this reduces strand thickness slightly (approximately 10%), it enhances aesthetics and provides a more uniform plane.

Industry Source References

Order Premium Diamond Expanded Metal Solutions

Experience the Chen Cai Metal difference in quality and technical excellence. Request a custom quote for your project specifications.

Request Product Information

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)