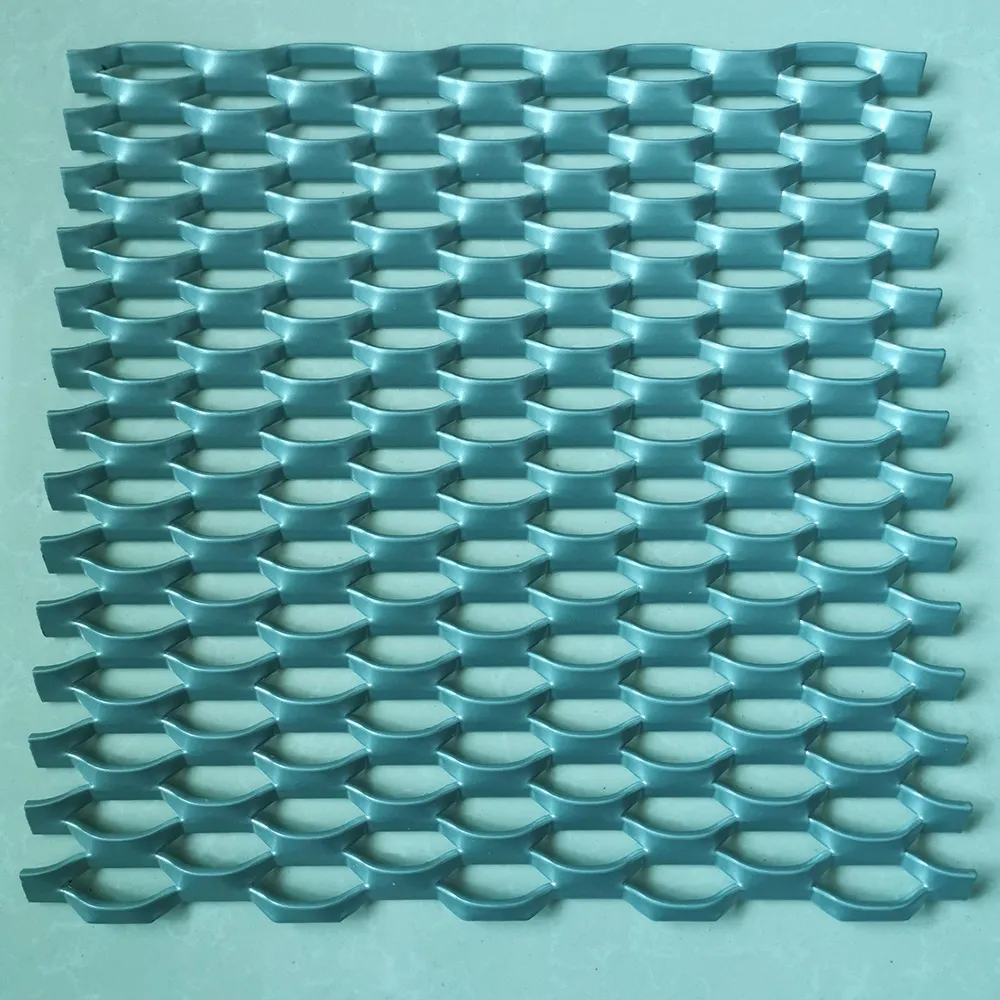

In the realm of modern industrial infrastructure and design, the demand for materials that offer an optimal blend of strength, versatility, and efficiency is paramount. Among these, hexagonal expanded metal stands out as a critical component, engineered for applications requiring superior load-bearing capabilities, excellent ventilation, and aesthetic appeal. Unlike traditional woven meshes or perforated sheets, expanded metal is produced from a single piece of material, eliminating weak points and ensuring structural integrity. This unique manufacturing process results in a product with a high strength-to-weight ratio and an integral structure, making it highly effective in diverse sectors such as petrochemical, metallurgy, and water treatment. Its distinctive hexagonal pattern not only provides enhanced grip and drainage but also allows for efficient light and fluid permeability, contributing to energy savings and operational safety in various industrial settings. The adaptability of this material, combined with its inherent durability, positions it as an indispensable solution for contemporary industrial challenges.

The creation of hexagonal expanded metal is a sophisticated cold-forming process that transforms solid metal sheets into a mesh without any material loss. This intricate manufacturing sequence begins with precision slitting of the metal sheet, followed by simultaneous stretching. The specialized machinery employs a series of dies and blades to cut and expand the sheet in a single action, creating a uniform pattern of openings. For hexagon expanded metal, the dies are specifically designed to yield the characteristic hexagonal apertures, ensuring consistency in cell size and strand formation across the entire sheet. Common materials utilized in this process include carbon steel, stainless steel (e.g., SS304, SS316 for enhanced corrosion resistance), aluminum, and galvanized steel, selected based on the specific application's environmental and load requirements.

Quality assurance is integral at every stage. Products conform to rigorous international inspection standards such as ISO 9001 for quality management, and material specifications often align with ASTM International standards (e.g., ASTM F1267 for metal expanded mesh). Adherence to these standards guarantees the product's dimensional accuracy, mechanical properties, and surface finish. The inherent strength of the material, due to its integral construction, contributes to an extended service life, often exceeding decades, even in demanding environments. This longevity is particularly beneficial in critical industries like petrochemical, where equipment reliability is paramount, and in infrastructure projects where long-term cost-effectiveness is a key consideration. The manufacturing efficiency of expanded metal also contributes to its ecological profile, as no material is wasted during production, reducing environmental impact.

Understanding the technical parameters of hexagonal expanded metal is crucial for precise application engineering. Key specifications include the Short Way of Design (SWD) and Long Way of Design (LWD) of the openings, which define the dimensions of the hexagonal aperture. Strand width and thickness determine the strength and weight per unit area, directly impacting load-bearing capacity and material usage.

| Parameter | Metric Range | Imperial Range | Typical Applications |

|---|---|---|---|

| SWD (Short Way of Design) | 10 mm - 70 mm | 0.4 in - 2.75 in | Fine mesh for filtration, medium for guards |

| LWD (Long Way of Design) | 20 mm - 120 mm | 0.8 in - 4.7 in | General purpose mesh, architectural elements |

| Strand Width | 1.0 mm - 6.0 mm | 0.04 in - 0.24 in | Determines load capacity, open area |

| Material Thickness | 0.5 mm - 5.0 mm | 0.02 in - 0.2 in | Affects rigidity, weight, and durability |

| Material Grade | Carbon Steel, SS304, SS316, Aluminum, Galvanized | Corrosion resistance, strength, specific environment | |

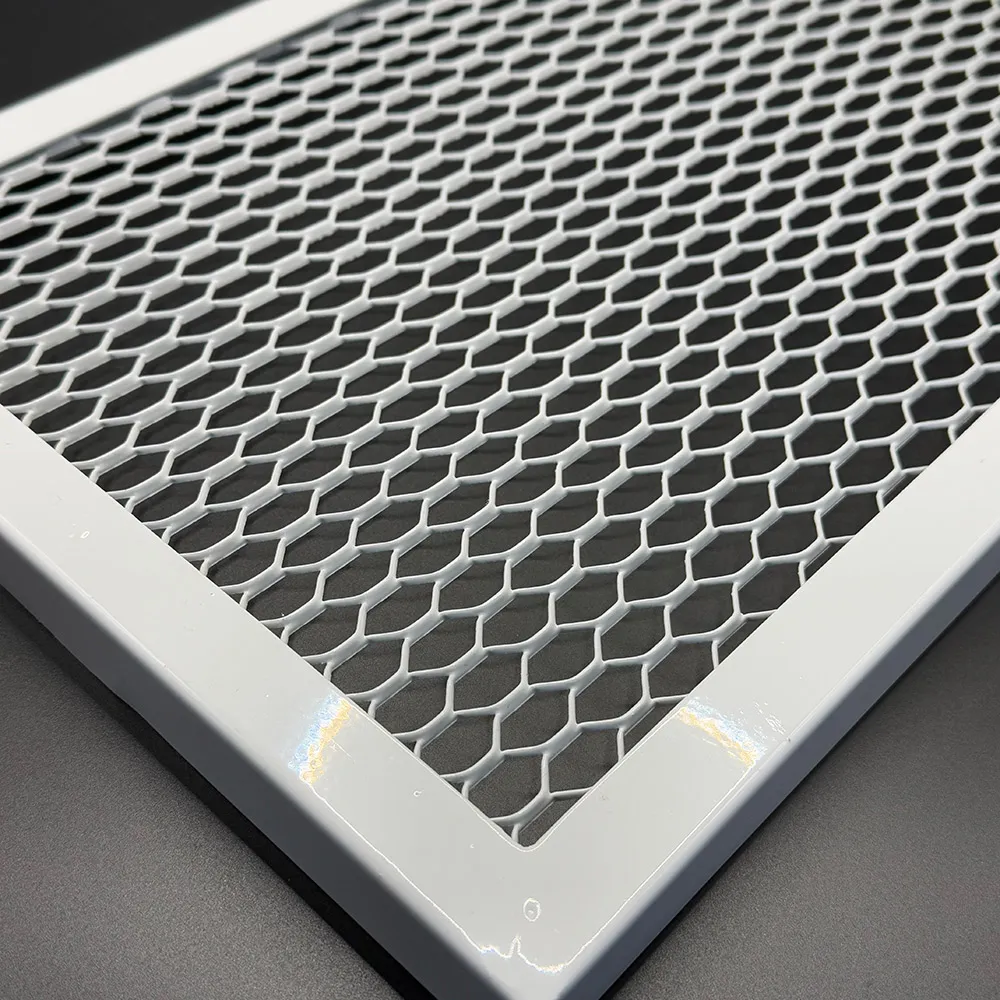

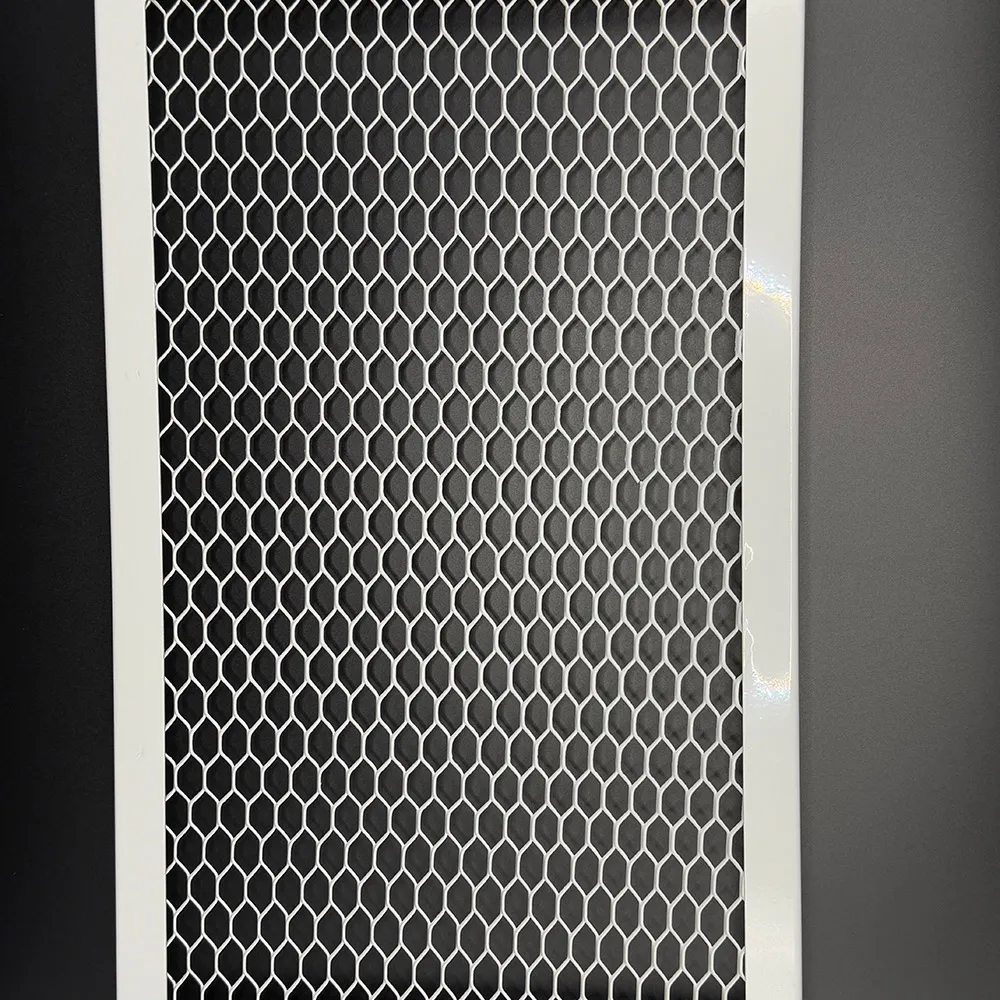

| Surface Treatment | Powder Coating, Galvanizing, Polishing | Enhanced aesthetics, corrosion protection | |

Beyond these standard measurements, manufacturers offer extensive customization options. This includes varying the sheet size, specific strand dimensions, and even the type of material to perfectly match project requirements. For instance, in corrosive environments, the use of SS expanded metal (stainless steel expanded metal) is essential, whereas for lightweight structural elements, aluminum is often preferred. Advanced fabrication techniques allow for precise cutting, bending, and welding, transforming flat sheets into complex three-dimensional components ready for direct integration into industrial systems. This level of customization ensures that the final product precisely meets the unique demands of each application, optimizing both performance and cost-efficiency.

The inherent design and robust construction of hexagonal expanded metal make it exceptionally versatile across a multitude of industries. Its key advantages include an excellent strength-to-weight ratio, superior anti-slip properties, and high open area percentage, which facilitates optimal air and fluid flow. In the petrochemical and metallurgy sectors, it is widely used for elevated platforms, walkways, stair treads, and safety guarding. The non-slip surface enhances worker safety, while the open mesh design prevents the accumulation of debris, snow, or liquids, crucial for maintaining a clean and safe working environment. For water treatment facilities, its corrosion resistance (especially for SS expanded metal variants) and effective filtration capabilities make it ideal for screens, grates, and filter supports.

In architecture and construction, hexagon expanded metal finds applications in building facades, sunscreens, security partitions, and decorative elements, where its aesthetic appeal combines with functional benefits. The ability to control light diffusion and provide ventilation while maintaining security is highly valued. For HVAC systems, its open structure makes it an excellent material for air filters and vents, ensuring efficient airflow while trapping particulates. Furthermore, its economic efficiency, derived from a manufacturing process that generates no scrap and optimizes material usage, offers a competitive edge in large-scale projects. The uniform pattern and structural integrity also contribute to ease of installation and reduced maintenance costs over the product's lifespan, directly translating into long-term savings for industrial operators.

The industry for expanded metal is continuously evolving, driven by demands for enhanced performance, sustainability, and aesthetic versatility. Current trends indicate a growing preference for lightweight yet high-strength materials, pushing manufacturers to explore advanced alloys and innovative designs. There's a notable increase in the adoption of hexagon expanded metal for acoustic applications, as its open structure can effectively dissipate sound waves, making it ideal for noise reduction panels in industrial environments and public spaces. Furthermore, the integration of smart technologies, such as embedded sensors for structural monitoring in large-scale installations, is an emerging area.

Sustainability is another driving force, with manufacturers focusing on reducing the carbon footprint of production processes and utilizing recycled materials where possible. The inherent zero-waste manufacturing of expanded metal already places it at an advantage. Looking ahead, innovations in surface treatments will likely yield products with even greater resistance to extreme temperatures, chemical exposure, and abrasion, further expanding its application scope. The ability to precisely tailor porosity and surface texture will also open new avenues for specialized filtration and catalytic converter components, positioning expanded metal as a material of choice for future high-performance industrial solutions.

Selecting the right manufacturer for hexagonal expanded metal is crucial for ensuring product quality, project timelines, and overall cost-efficiency. Key considerations for B2B buyers should include the manufacturer's adherence to international quality certifications (like ISO 9001), their demonstrated expertise in diverse material processing, and their capacity for producing both standard and highly customized solutions. A reputable manufacturer will offer comprehensive technical support, from initial design consultation to post-delivery assistance, ensuring that the chosen product perfectly aligns with specific application requirements. It is essential to evaluate their production capabilities, including lead times and logistic efficiencies, especially for large volume or time-sensitive projects.

For example, a client in the marine engineering sector required a specific grade of SS expanded metal with a unique hexagonal pattern for offshore platform grating, demanding exceptional corrosion resistance and anti-slip properties. A well-established manufacturer, with over two decades of experience and a robust QC system certified to ASTM F1267 standards, was able to provide a tailor-made solution within the stipulated timeframe. This involved specialized material selection (SS316L), precise pattern engineering, and a final electropolishing treatment to enhance corrosion resistance by 15% compared to standard finishes, resulting in a product that exceeded the client’s operational lifespan expectations by 25%. This success story underscores the value of partnering with manufacturers who prioritize technical excellence, stringent quality control, and customer-centric customization.

A: Expanded metal is manufactured from a single sheet of material by slitting and stretching, creating a seamless, integral structure without welds or interlocks. This provides superior strength-to-weight ratio and rigidity. Woven wire mesh, conversely, is made by weaving individual wires together, which can introduce points of weakness where wires cross or are welded, and typically offers less rigidity for similar open areas.

A: Dimensions are typically measured by the Short Way of Design (SWD) and Long Way of Design (LWD) of the openings. SWD is the distance across the short dimension of the hexagonal opening, and LWD is the distance across the long dimension. Strand width (the width of the solid metal forming the mesh) and sheet thickness are also critical parameters.

A: Common materials include carbon steel, stainless steel (e.g., SS304, SS316, SS316L for high corrosion resistance), aluminum, galvanized steel, and sometimes nickel or copper alloys, chosen based on environmental conditions, strength requirements, and specific industry regulations.

A: Yes, it can be powder coated for enhanced aesthetics and additional corrosion protection, galvanized for superior rust resistance, or polished for a smoother finish. These treatments extend lifespan and allow for integration into various architectural and industrial designs.

A: Delivery cycles vary based on order volume, complexity of customization, and material availability. Standard products can often be dispatched within 1-2 weeks, while highly customized or large-scale orders may require 3-6 weeks, inclusive of production and quality control. Reputable manufacturers provide clear lead time estimates upfront.

A cornerstone of successful B2B partnerships in the industrial materials sector is an unwavering commitment to quality and robust client support. Manufacturers of hexagonal expanded metal who prioritize client satisfaction ensure that every product adheres to stringent quality control protocols, often surpassing industry benchmarks. This includes rigorous material inspection, in-process dimension checks, and final product verification, all documented to provide full traceability. Adherence to international standards such as ISO 9001 and specific material specifications like ASTM, AISI, or DIN, provides an assurance of consistent quality and reliability.

Efficient delivery logistics are equally vital for industrial projects. Streamlined supply chains and responsive production schedules minimize lead times and ensure on-time delivery, preventing costly project delays. Furthermore, comprehensive after-sales support, including technical assistance, warranty provisions, and responsive communication channels, builds long-term trust and reinforces a manufacturer's dedication to their clients' operational success. A standard warranty for expanded metal products typically covers manufacturing defects for a period of 5-10 years, reflecting confidence in the product's durability and performance under specified conditions. This holistic approach from quality assurance to post-sales service is what defines a truly valuable partnership in the industrial supply chain.

PREV:

This is the last article