The demand for versatile and high-performance materials in industrial applications continues to escalate, driving innovation across manufacturing sectors. Among the most adaptable materials, round perforated metal stands out as a critical component in countless designs, from advanced filtration systems to modern architectural facades. Its unique combination of strength, open area, and aesthetic appeal makes it indispensable for engineers and designers aiming for optimal functionality and efficiency. Current industry trends highlight a growing preference for lightweight, corrosion-resistant, and energy-efficient materials, all characteristics inherent to high-quality perforated sheets. This material's ability to facilitate airflow, diffuse light, and reduce noise while maintaining structural integrity positions it at the forefront of sustainable and high-performance material solutions.

The versatility extends beyond basic functionality; it encompasses the ability to customize for specific operational demands. Whether it’s for sound attenuation in industrial machinery, precise screening in agricultural processes, or durable enclosures in petrochemical plants, the tailored properties of perforated metal ensure peak performance. The ongoing global push for sustainable manufacturing practices further solidifies the position of round perforated metal as an eco-friendly choice, given its recyclability and long service life. This material offers a strategic advantage by optimizing material usage and improving operational efficiencies across a diverse range of applications, contributing to both economic and environmental benefits.

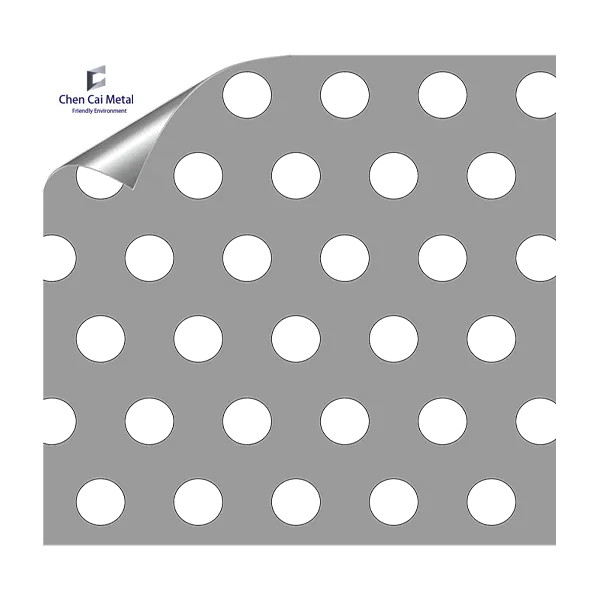

Understanding the precise technical parameters is crucial for selecting the appropriate round perforated metal sheet for any given application. Key specifications include material type, hole size, pitch, thickness (gauge), and the overall sheet dimensions. The arrangement of holes, typically staggered (60° or 45°) or straight, significantly influences the open area and structural integrity. A staggered 60° pattern, common in our Round Staggered 60° Perforated Sheet, provides an excellent balance of high open area and strength, making it ideal for filters, screens, and aesthetic panels. The 'open area' is the total area of the holes divided by the total area of the sheet, expressed as a percentage, directly impacting flow rates and light diffusion.

Below is a table summarizing typical parameters for round perforated metal, offering insights into the range of possibilities available for various industrial needs. These parameters are critical for engineers designing systems where factors such as air flow, liquid filtration, sound absorption, or aesthetic appeal are paramount. Precise manufacturing ensures that each sheet meets these specifications, guaranteeing consistent performance and durability in demanding environments. This meticulous attention to detail during production allows for the material to be precisely integrated into complex systems, enhancing overall system reliability and efficiency.

| Parameter | Typical Range / Options | Significance |

|---|---|---|

| Material Grade | Stainless Steel (304, 316), Carbon Steel, Galvanized Steel, Aluminum (1100, 3003, 5052), Copper, Brass | Corrosion resistance, strength-to-weight ratio, conductivity, cost |

| Hole Diameter | 0.5 mm to 50 mm (0.02" to 2") | Filtration capacity, aesthetic appearance, flow rate |

| Pitch (Center-to-Center) | 1.5 mm to 70 mm (0.06" to 2.75") | Determines open area and overall rigidity |

| Open Area Percentage | Up to 70% (typical range 20%-60%) | Flow efficiency, light transmission, sound absorption |

| Sheet Thickness | 0.3 mm to 10 mm (0.012" to 0.394" / 30 ga to 0.375") | Durability, load-bearing capacity, weight |

| Standard Sheet Sizes | 1000x2000mm, 1220x2440mm, 1500x3000mm (4'x8', 4'x10', 5'x10') and custom | Ease of handling, material yield, fabrication cost |

| Hole Pattern | Staggered 60° (most common), Staggered 45°, Straight Row | Structural strength, open area, aesthetic appeal |

The production of high-quality round perforated metal sheet involves a precise and sophisticated manufacturing process, primarily utilizing advanced punching and stamping techniques. This process begins with the selection of premium raw materials, such as hot-rolled or cold-rolled steel, various grades of stainless steel (e.g., 304, 316 for corrosion resistance), aluminum alloys (e.g., 1100, 3003, 5052 for lightweight applications), copper, or brass. The chosen metal coil or sheet is fed into a high-speed press equipped with custom-designed dies. These dies are engineered to create precise round holes in various patterns, most commonly the staggered 60° arrangement, which optimizes strength while maximizing open area.

Following the perforation, the sheets undergo several crucial finishing stages. De-burring removes any sharp edges or burrs resulting from the punching process, ensuring safety and a smooth finish. Flattening (or leveling) ensures the sheet is perfectly planar, essential for subsequent fabrication and installation. Finally, cleaning removes any residues, and depending on the material, additional surface treatments like galvanizing, anodizing, or powder coating may be applied to enhance durability, corrosion resistance, or aesthetic appeal. Throughout this entire process, strict quality control measures, adhering to international standards such as ISO 9001 and ASTM, are implemented. These standards ensure precise hole dimensions, uniform spacing, and overall product integrity. The typical service life of a well-manufactured perforated metal sheet can exceed 20-30 years in non-aggressive environments, showcasing its long-term value and robust performance.

The choice of material for round perforated metal is paramount, directly influencing its performance characteristics and suitability for specific applications. For instance, in highly corrosive environments like those found in petrochemical or wastewater treatment plants, stainless steel (SS304 or SS316) is preferred due to its superior resistance to rust and chemical degradation. This ensures a prolonged service life and reduced maintenance costs, making it a cost-effective solution in the long run. In applications where weight is a critical factor, such as in aerospace components or transportation systems, round hole aluminum perforated sheet offers an excellent strength-to-weight ratio, contributing to overall energy efficiency and reduced operational burdens. Its lightweight nature also simplifies installation and handling.

Beyond material composition, the inherent design of perforated metal offers several technical advantages. The precisely engineered holes allow for controlled passage of light, air, and liquids, making it ideal for ventilation systems, sunshades, and various filtration processes. In acoustic applications, the perforations can effectively dampen sound waves, contributing to quieter industrial environments or public spaces. Furthermore, the robust nature of metal sheet perforated round hole ensures durability against impact and vibration, essential for machinery guards or protective barriers. These advantages translate into tangible benefits like energy savings through optimized airflow, enhanced safety, and improved operational efficiency, making perforated metals a smart investment for industrial and commercial projects alike.

The broad applicability of round perforated metal spans a multitude of industries, driven by its adaptable properties and robust performance. In the petrochemical sector, these sheets are extensively used for catalyst support grids, protective cages around sensitive equipment, and filtration screens in processing units, where their corrosion resistance and structural integrity are crucial for safety and operational continuity. For the metallurgical industry, they serve as screens for material sorting, protective barriers for machinery, and components in heat exchange systems, enduring high temperatures and abrasive conditions with remarkable resilience. Within the water supply and drainage systems, round perforated metal sheet finds application in strainers, well screens, and various filtration components, preventing blockages and ensuring clean water flow.

Beyond these core industrial applications, the aesthetic and functional versatility of round perforated metal is leveraged in architectural design for building facades, sunscreens, and interior design elements that enhance natural light diffusion and ventilation. In HVAC systems, they are vital for air diffusers and grilles, optimizing airflow distribution and reducing noise. Our experience includes providing custom perforated solutions for diverse projects, from large-scale industrial filtration arrays to intricate decorative panels for commercial buildings. For example, a recent project involved supplying large-format round hole aluminum perforated sheet for a data center's cooling infrastructure, demonstrating its effectiveness in critical climate control applications where precise airflow and lightweight construction were essential.

Recognizing that standard specifications may not always meet unique project requirements, offering comprehensive customization solutions for round perforated metal is a cornerstone of advanced manufacturing. This includes tailoring parameters such as specific hole diameters and patterns, precise open area percentages, custom sheet dimensions, and a wide array of material choices beyond the common stainless steel and aluminum. Specialized fabrication services, including bending, welding, rolling, and finishing, transform flat perforated sheets into complex components ready for immediate integration into your systems. This bespoke approach ensures that the final product perfectly aligns with the client's engineering specifications and functional needs, optimizing performance and reducing on-site modifications.

Our engineering team collaborates closely with clients from conceptualization through to production, providing expert advice on material selection, design optimization, and cost-efficiency. This consultative approach helps to refine project scope and ensures that every aspect of the round perforated metal solution is meticulously planned. For instance, for an acoustic panel application, we might recommend specific hole sizes and open areas combined with a certain material thickness to achieve desired sound absorption coefficients, while for a robust industrial screen, the focus would be on material strength and wear resistance. This dedication to customized solutions and technical support distinguishes leading manufacturers and provides significant value to B2B clients seeking precise, high-performance materials.

For B2B buyers of round perforated metal, ensuring product quality and supplier reliability is paramount. Reputable manufacturers adhere to stringent quality management systems, typically certified under ISO 9001, which guarantees consistency in manufacturing processes and product output. This commitment extends to meticulous material sourcing, precise manufacturing tolerances, and comprehensive post-production inspections. Adherence to international standards like ASTM, ANSI, and local regulations ensures that the products meet specified mechanical properties, dimensions, and performance criteria. Testing data, including tensile strength, yield strength, elongation, and open area verification, should be readily available to substantiate product claims and build trust with discerning clients. Choosing a manufacturer with a proven track record, extensive service years, and a portfolio of successful projects provides additional assurance.

When comparing manufacturers of round perforated metal sheet, consider several key factors beyond just price. Assess their capabilities for customization, the breadth of their material inventory, lead times, and post-sales support. A manufacturer that offers dedicated technical consultation, provides clear delivery schedules, and stands behind their products with robust warranty commitments demonstrates a higher level of trustworthiness and professionalism. Look for clear communication channels, transparent project management, and a willingness to provide references or case studies. A reliable partner will not only supply the material but also act as an extension of your engineering team, contributing to the overall success and longevity of your projects.

The open area, expressed as a percentage, indicates the total area of the holes relative to the total area of the sheet. It's a critical parameter that directly influences the flow rate of air, liquid, or light, as well as the sound attenuation properties and the structural integrity of the sheet. Higher open areas typically mean less structural strength but greater flow and light transmission, while lower open areas offer more rigidity but less permeability.

Material selection depends heavily on the application environment and required properties. Stainless steel (304, 316) is ideal for corrosive environments or hygienic applications. Aluminum is preferred for lightweight structures or when electrical conductivity is needed. Carbon steel (often galvanized or powder-coated) offers cost-effectiveness for general purpose applications requiring strength. Our technical experts can provide guidance based on your specific operational conditions and budget.

Absolutely. Customization is a key strength for perforated metal manufacturers. We can produce sheets with specific hole sizes, patterns (e.g., staggered 60° for optimal open area), non-standard dimensions, and a variety of material thicknesses. We also offer secondary fabrication services like cutting, bending, welding, and finishing (e.g., powder coating, anodizing) to meet precise project requirements. This ensures the perforated metal integrates seamlessly into your larger assemblies.

Lead times vary depending on the complexity of the order, quantity, material availability, and current production schedule. Standard sizes and materials usually have shorter lead times. For custom orders, our sales team provides a detailed production schedule upon order confirmation. We prioritize efficient production and reliable logistics to ensure timely delivery, and we communicate proactively about any potential changes to the delivery schedule. Expedited options may be available for urgent requirements.

Ensuring a seamless procurement experience for our B2B partners, we offer reliable global delivery services for our round perforated metal products. Our logistics team works diligently to arrange secure and timely shipments, whether by land, sea, or air freight, to meet your project timelines. We provide clear communication regarding delivery schedules and tracking information, ensuring full transparency from our factory to your site. Each product is carefully packaged to prevent damage during transit, safeguarding its quality upon arrival.

Our commitment to quality is underscored by a comprehensive warranty policy covering material defects and manufacturing flaws. This warranty reflects our confidence in the durability and performance of our round perforated metal sheet products. Beyond delivery, our dedicated customer support team is available to assist with any technical queries, post-sales support, or future orders. We pride ourselves on building long-term relationships through exceptional product quality and unwavering customer service, ensuring that your investment in our perforated metal solutions delivers sustained value.

The advanced characteristics and versatile applications of round perforated metal establish it as an indispensable material in modern industrial and architectural design. Its capacity for customization, combined with inherent properties like controlled permeability, structural integrity, and aesthetic appeal, provides unparalleled solutions for a wide range of complex challenges. From enhancing energy efficiency in HVAC systems to providing robust filtration in petrochemical plants, the strategic deployment of perforated metal contributes significantly to operational excellence and sustainability goals. As industries continue to evolve, the demand for high-performance, adaptable materials will only grow, positioning quality perforated metals at the forefront of innovation. Partnering with a reputable manufacturer that prioritizes precision engineering, quality assurance, and comprehensive customer support ensures that your projects benefit from the full potential of this exceptional material.

PREV:

This is the last article