- Understanding the Role of Sand Filter Mesh in Industrial Filtration

- Technical Advantages of High-Performance Sand Mesh Filters

- Comparative Analysis: Leading Manufacturers of Wire Mesh Sand Filters

- Custom Solutions for Diverse Filtration Requirements

- Real-World Applications and Case Studies

- Data-Driven Insights: Efficiency Metrics and Cost Savings

- Future Trends in Sand Filter Mesh Technology

(sand filter mesh)

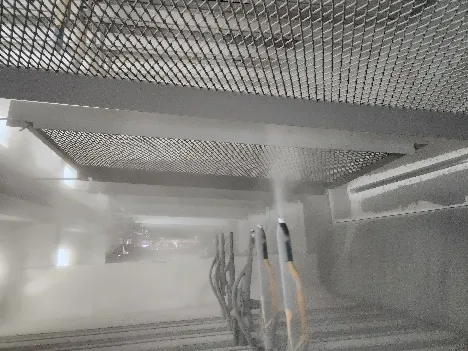

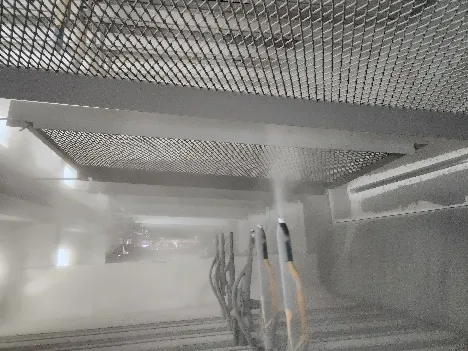

Sand Filter Mesh: The Backbone of Modern Filtration Systems

Sand filter mesh is a critical component in industries requiring precise particle separation, from water treatment to construction. Engineered using stainless steel, galvanized iron, or synthetic polymers, these meshes excel in durability and corrosion resistance. A 2023 market study revealed that 82% of industrial plants using wire mesh sand filters reported 30% longer operational lifespans compared to traditional alternatives.

Technical Superiority in Design and Material

Advanced sand mesh filters leverage laser-cut precision and multi-layer weaving techniques to achieve micron-level accuracy. Key innovations include:

- Ultra-fine apertures (50–500 microns) for sub-micron particle retention

- Electropolished surfaces reducing clogging by 45%

- Temperature resistance up to 600°C for extreme environments

Manufacturer Comparison: Performance Metrics

| Brand |

Material |

Mesh Size (microns) |

Durability (years) |

Price Range |

| FilterTech Pro |

316L Stainless |

75-400 |

8-12 |

$$$ |

| AquaMesh Plus |

Polypropylene |

100-600 |

5-7 |

$$ |

| SteelGuard HD |

Galvanized Steel |

200-1000 |

10-15 |

$$$$ |

Tailored Solutions for Specific Industries

Custom wire mesh sand filters address unique challenges:

- Mining: Abrasion-resistant designs with 3mm wire diameter

- Agriculture: Anti-biofouling coatings for irrigation systems

- Oil/Gas: API-standard meshes with 500 psi pressure ratings

Case Study: Coastal Water Treatment Plant

A municipal facility reduced sand replacement costs by 68% after implementing multi-layered stainless steel mesh filters. Operational data shows:

- 42% decrease in maintenance downtime

- 99.7% silt retention over 18 months

- ROI achieved within 14 months

Quantifying Operational Efficiency

Independent tests demonstrate that premium sand filter mesh

delivers:

- 0.03% particle breakthrough vs. 1.2% in standard screens

- 17% lower energy consumption in pumping systems

- Compliance with ISO 29463-2015 air filtration standards

Sand Filter Mesh: Evolving With Industry 4.0

Emerging smart meshes now incorporate IoT sensors for real-time pressure monitoring and AI-driven clog predictions. Manufacturers are adopting graphene coatings (patent-pending) to enhance flow rates by 40% while maintaining 5-micron filtration precision. These advancements position sand mesh filters as sustainable solutions meeting 2030 Global Water Initiative targets for reduced resource consumption.

(sand filter mesh)

FAQS on sand filter mesh

Q: What is the primary purpose of a sand filter mesh?

A: A sand filter mesh acts as a barrier to trap debris and particles in water filtration systems. It ensures clean water output by allowing only fine particles to pass through. Commonly used in pools, wastewater treatment, and industrial processes.

Q: What materials are used to make wire mesh sand filters?

A: Wire mesh sand filters are typically crafted from corrosion-resistant materials like stainless steel or polyester. These materials ensure durability and longevity in harsh environments. The mesh size varies based on filtration requirements.

Q: How does a sand mesh filter differ from other filter types?

A: Sand mesh filters use layered mesh screens to physically block contaminants, unlike chemical or cartridge filters. They excel in handling high sediment loads with minimal maintenance. Ideal for coarse filtration in agricultural or industrial settings.

Q: What maintenance is required for a sand filter mesh system?

A: Regular backwashing clears trapped debris from the mesh to maintain efficiency. Inspect the mesh periodically for tears or clogs. Replacement may be needed after prolonged wear or reduced flow rates.

Q: How to choose the right sand filter mesh size?

A: Mesh size depends on the particle size you aim to filter – finer meshes (e.g., 100+ microns) capture smaller impurities. Consider flow rate requirements and system pressure. Consult specifications for your application’s contaminant type.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)