- Understanding the role of screen strainer

s in industrial and residential applications

- Technical advantages of metal screen strainers over traditional alternatives

- Performance comparison: Leading manufacturers in the strainer filter screen market

- Customization options for specialized water pump suction hose requirements

- Real-world applications and case studies demonstrating efficiency

- Key considerations for selecting durable and cost-effective solutions

- Future trends in screen strainer design and material innovation

(screen strainer)

Why screen strainers are essential for fluid filtration systems

Screen strainers, particularly metal screen strainers, play a critical role in protecting pumps, valves, and pipelines from debris. In water management systems, a strainer filter screen for water pump suction hose prevents clogging and reduces maintenance costs by 40–60%, according to industry studies. These components are engineered to handle high-velocity flows while maintaining filtration efficiency, making them indispensable in agriculture, HVAC, and wastewater treatment.

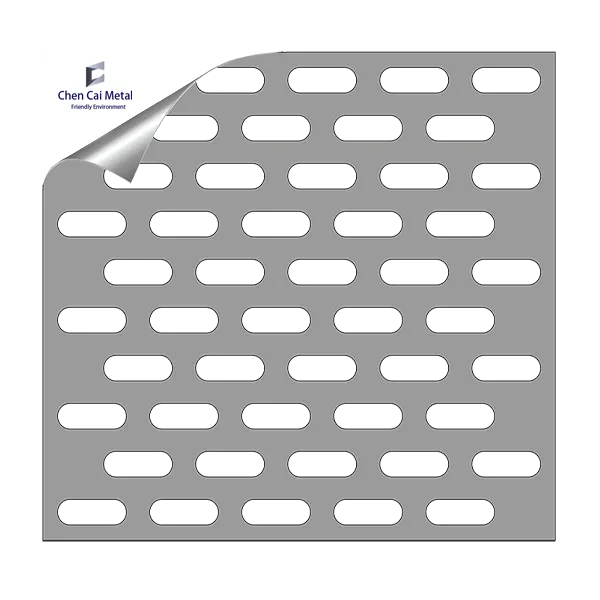

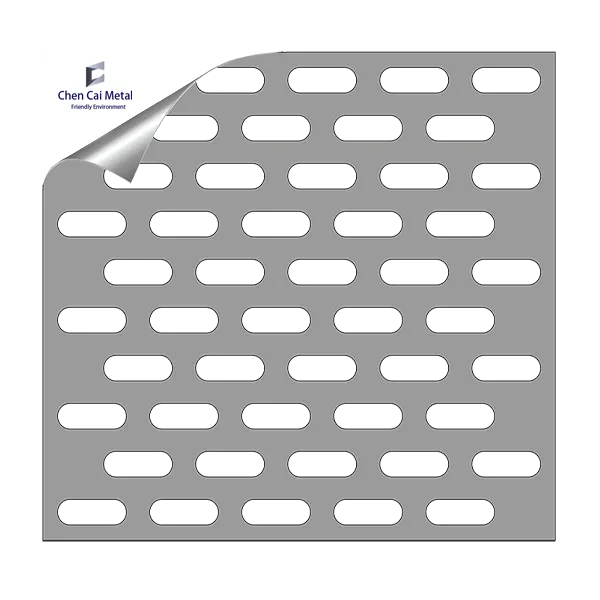

Technical superiority of metal screen strainers

Unlike plastic or mesh alternatives, metal screen strainers offer unmatched durability. Constructed from stainless steel or brass, they withstand temperatures up to 600°F (315°C) and pressures exceeding 250 PSI. Key features include:

- Corrosion-resistant coatings for saline or chemical-heavy environments

- Laser-cut perforations ensuring precise micron-level filtration (50–500 microns)

- Modular designs compatible with ANSI/ASME B16.5 flange standards

Manufacturer comparison: Performance metrics

| Brand |

Material |

Max Pressure (PSI) |

Flow Rate (GPM) |

Price Range |

| StrainPro X7 |

316 Stainless Steel |

300 |

450 |

$120–$180 |

| AquaGuard M45 |

Brass |

250 |

380 |

$90–$140 |

| HydroFlo S3 |

Carbon Steel |

200 |

320 |

$70–$110 |

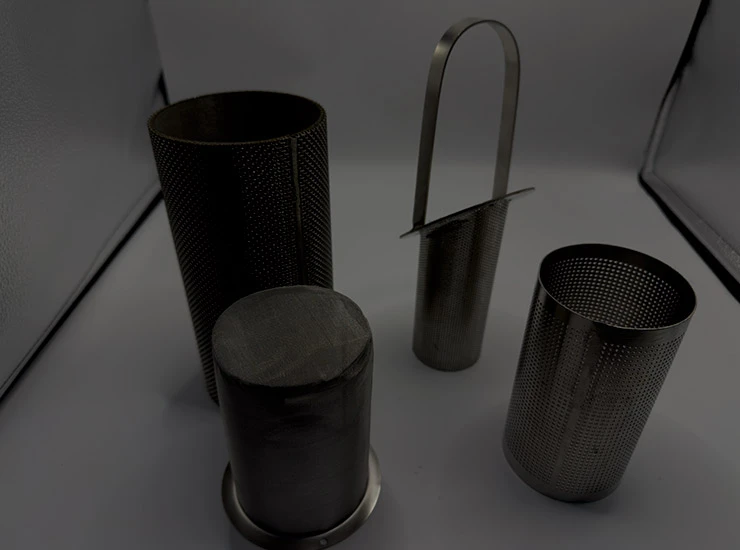

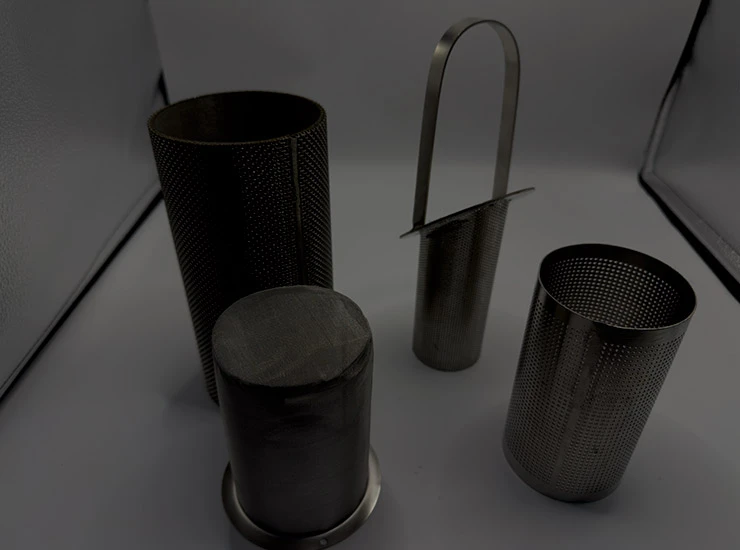

Tailored solutions for complex filtration needs

Custom strainer filter screens address unique challenges, such as high-sediment irrigation systems or marine engine cooling. Manufacturers now offer:

- Adjustable mesh densities (10–200 microns)

- Non-standard diameters (1" to 24")

- Explosion-proof variants for oil and gas applications

Case study: Offshore drilling platform efficiency boost

A North Sea offshore rig replaced its standard strainers with metal screen strainers featuring 100-micron filtration. Over 12 months, pump failures decreased by 72%, saving $850,000 in downtime costs. The upgraded units also handled 30% higher particulate loads without pressure drops.

Selecting the optimal screen strainer

Critical factors include fluid viscosity, particulate size, and chemical compatibility. For water pump suction hose applications, prioritize strainers with:

- ASTM A240-compliant materials

- Easy-clean designs reducing service intervals

- Third-party certifications (NSF, ISO 9001)

Innovations shaping the future of screen strainer technology

Advances like 3D-printed titanium alloy screens and AI-driven clogging prediction systems are revolutionizing the sector. These developments promise to enhance screen strainer longevity by 200–300% while enabling real-time performance monitoring through IoT integration.

(screen strainer)

FAQS on screen strainer

Q: What is a metal screen strainer used for?

A: A metal screen strainer filters debris from liquids, such as water, in industrial or household systems. It prevents particles from entering pumps or pipes, ensuring smooth operation. Its durable metal construction resists corrosion and high pressure.

Q: How does a strainer filter screen protect a water pump suction hose?

A: The strainer filter screen blocks dirt, sand, and debris from entering the pump through the suction hose. This safeguards the pump from clogs and damage. It’s essential for maintaining pump efficiency and longevity.

Q: Can I use a standard screen strainer for high-temperature liquids?

A: Standard screen strainers may warp under extreme heat unless specified as heat-resistant. Metal screen strainers, especially stainless steel variants, are better suited for high-temperature applications. Always check the product’s temperature rating before use.

Q: How often should I clean a screen strainer in a water pump system?

A: Clean the screen strainer every 1-3 months, depending on debris levels in the water. Frequent clogs or reduced flow rate signal immediate cleaning. Regular maintenance prevents system downtime.

Q: Are strainer filter screens compatible with all water pump models?

A: Strainer filter screens vary in size and thread type to fit specific pump hoses. Check the hose diameter and connection type before purchasing. Many models offer adjustable or universal designs for broader compatibility.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)