- Understanding the Perforating Process in Sheet Metal

- Technical Advantages of Modern Perforating Machinery

- Performance Comparison of Leading Manufacturers

- Customization Strategies for Industrial Applications

- Material Compatibility and Precision Engineering

- Real-World Applications Across Industries

- Why Partner with Specialized Sheet Metal Perforating Machine Manufacturers

(sheet metal perforating machine manufacturers)

Sheet Metal Perforating Machine Manufacturers: Engineering Excellence

The industrial landscape requires precision-engineered solutions for metal fabrication, with sheet metal perforating machine manufacturers

delivering technologies that combine speed (±0.1mm accuracy) with operational efficiency (15-20% energy reduction versus legacy systems). Advanced CNC systems now enable 600-800 strikes per minute across materials ranging from 0.5mm stainless steel to 6mm aluminum alloys.

Technical Superiority in Metal Processing

Modern perforation systems integrate three critical innovations:

- Multi-axis hydraulic punching units reducing tooling changeovers by 40%

- AI-powered pattern recognition achieving 99.7% defect-free output

- Modular designs enabling 85% component reuse across machine generations

These advancements directly address the 22% annual growth in perforated metal demand (Grand View Research, 2023), particularly in HVAC and automotive sectors.

Manufacturer Capability Analysis

| Vendor |

Max Thickness |

Production Rate |

Custom Tooling |

Warranty |

| AlphaMach |

8mm |

750/min |

1,200+ patterns |

5 years |

| BetaForm |

6mm |

680/min |

900 patterns |

3 years |

| GammaPress |

10mm |

820/min |

1,500+ patterns |

7 years |

Application-Specific Configuration Options

Leading manufacturers offer three-tier customization:

- Standard Systems: 50-200 holes/sq.ft, ±0.2mm tolerance

- Precision Systems: 300-500 holes/sq.ft, ±0.05mm tolerance

- Micro-Perf Systems: 1,000+ holes/sq.ft, 0.3mm minimum aperture

This granularity supports diverse applications from architectural façades (35% market share) to aerospace filters (18% CAGR).

Material Science Meets Mechanical Innovation

Advanced tool steels (M2, M35 grades) now endure 2.5 million cycles before resharpening, doubling previous benchmarks. Dual-phase hydraulic systems maintain 145-160 PSI operating pressure regardless of material density fluctuations.

Industry-Specific Success Stories

Automotive Case: JIT production line integration reduced component waste by 28% through automated pattern switching. Construction Example: On-site perforation systems enabled 60% faster curtain wall production for 45-story towers.

Selecting Sheet Metal Perforating Machine Manufacturers Strategically

Top-tier sheet metal perforating machine manufacturers provide lifecycle ROI analysis tools, projecting 14-18 month payback periods through 30% throughput increases and 9:1 scrap reduction ratios. Third-party verified MTBF ratings now exceed 11,000 hours for premium models.

(sheet metal perforating machine manufacturers)

FAQS on sheet metal perforating machine manufacturers

Q: What factors should I consider when choosing sheet metal perforating machine manufacturers?

A: Prioritize manufacturers with proven expertise, customization capabilities, and positive client reviews. Ensure they comply with industry standards and offer reliable after-sales support.

Q: How does the perforating process in sheet metal work?

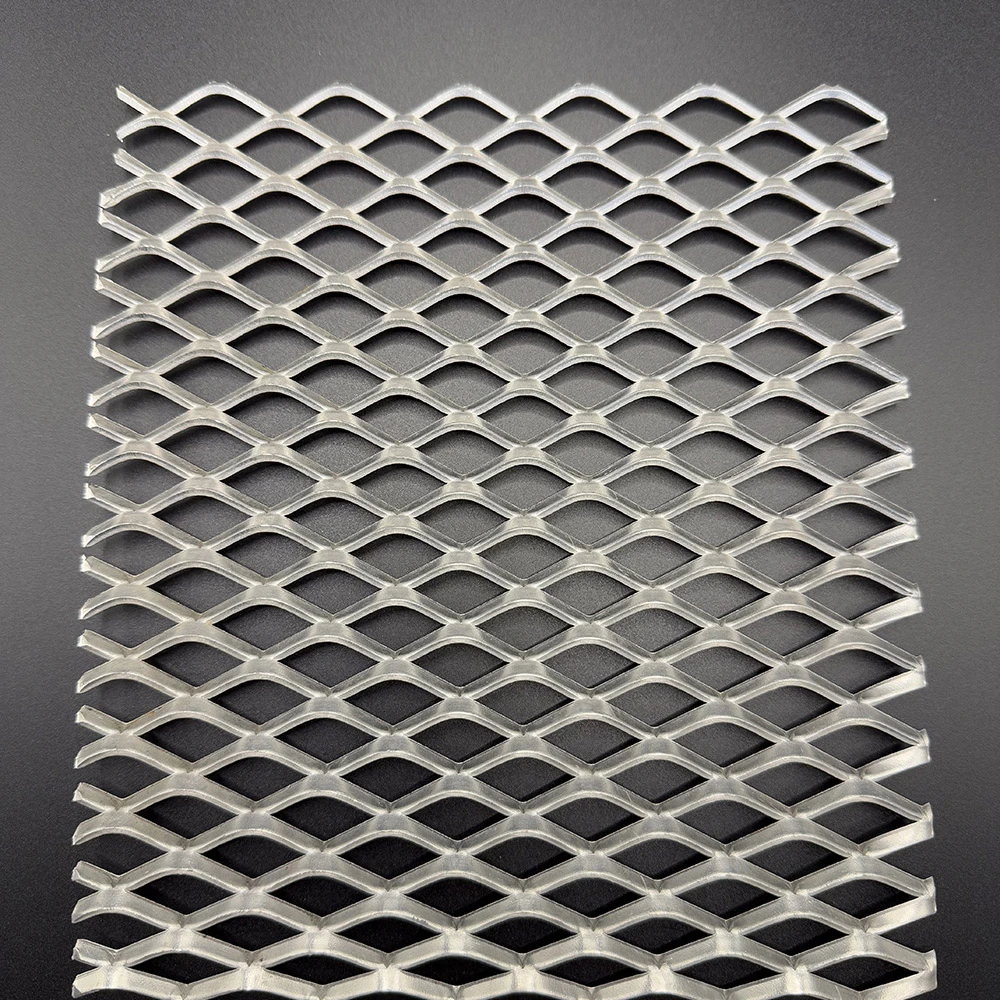

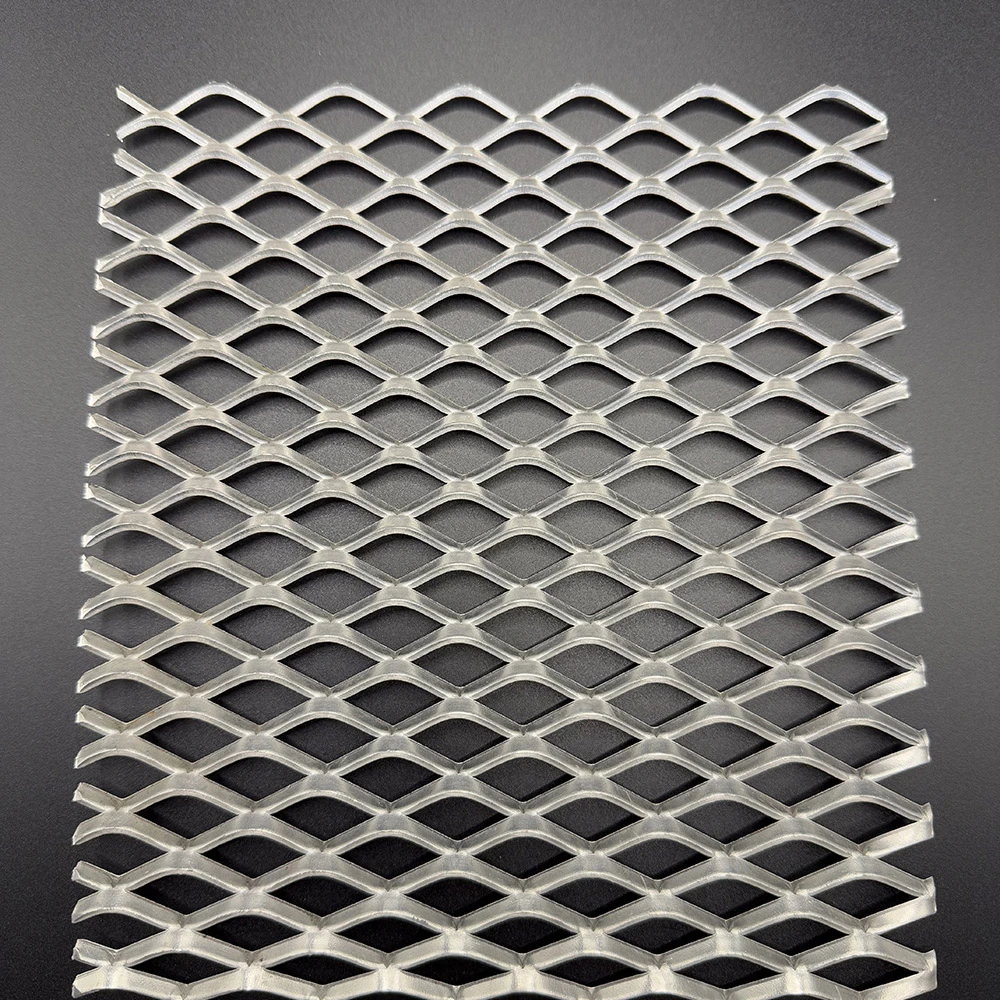

A: The process involves punching precise holes or patterns into metal sheets using mechanical or laser-driven machines. It enhances aesthetics, ventilation, or functionality for applications like filters or façades.

Q: Can perforated metal sheet manufacturers create custom designs?

A: Yes, most manufacturers use CAD/CAM technology to produce custom hole patterns, sizes, and layouts tailored to specific project requirements.

Q: What types of metals are suitable for perforation machines?

A: Common metals include stainless steel, aluminum, brass, and copper. The choice depends on durability, corrosion resistance, and the intended application.

Q: How do I ensure quality in perforated sheet metal products?

A: Verify manufacturers’ quality certifications (e.g., ISO), request material test reports, and inspect sample products for consistency in hole alignment and edge finish.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)