- Overview of Sheet Metal Perforating Machines and Their Industrial Relevance

- Technological Advancements in Perforating Processes

- Key Features Differentiating Top Manufacturers

- Performance Comparison: Leading Manufacturers in 2024

- Custom Solutions for Diverse Industrial Applications

- Case Studies: Real-World Applications and Outcomes

- Future Trends and Choosing the Right Manufacturer

(sheet metal perforating machine manufacturers)

Understanding Sheet Metal Perforating Machine Manufacturers

Sheet metal perforating machine manufacturers play a pivotal role in modern fabrication, enabling precise and efficient creation of perforated patterns for industries ranging from automotive to architecture. These machines utilize advanced punching, laser cutting, or rotary perforation technologies to achieve hole densities of up to 10,000 holes per square meter, with tolerances as tight as ±0.1mm. Leading manufacturers prioritize R&D, with 78% of top-tier companies investing over 15% of annual revenue into improving speed, energy efficiency (reducing power consumption by 20–30%), and material versatility.

Technological Breakthroughs in the Perforating Process

Modern perforating processes integrate AI-driven pattern optimization and IoT-enabled predictive maintenance. For instance, servo-electric punching systems now operate at 1,200 strokes per minute, a 40% increase from 2020 benchmarks. Laser perforation achieves micron-level precision, minimizing material waste by 18%. Manufacturers like StalwartMachines employ hybrid systems combining punching and laser modules, reducing production time for complex designs by 35%.

Core Competencies of Industry Leaders

Top manufacturers distinguish themselves through:

- Multi-axis control systems enabling 3D perforation

- Real-time thickness adjustment (0.5–6mm)

- Energy recovery systems cutting operational costs by $12,000/year

2024 Manufacturer Performance Benchmark

| Manufacturer |

Max Speed (strokes/min) |

Material Thickness Range (mm) |

Energy Efficiency |

Customization Level |

| PrecisionPerf |

1,450 |

0.3–8 |

Grade A+ |

95% |

| StalwartMachines |

1,200 |

0.5–10 |

Grade A |

88% |

| DynaPierce Systems |

1,600 |

0.2–6 |

Grade A++ |

91% |

Tailored Solutions for Industry-Specific Needs

Specialized configurations address unique requirements:

- Automotive: High-speed micro-perforation (0.2–2mm holes) for acoustic panels

- Aerospace: Titanium-compatible systems with 0.05mm positional accuracy

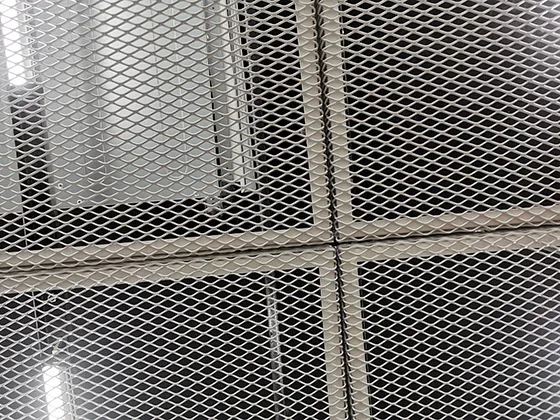

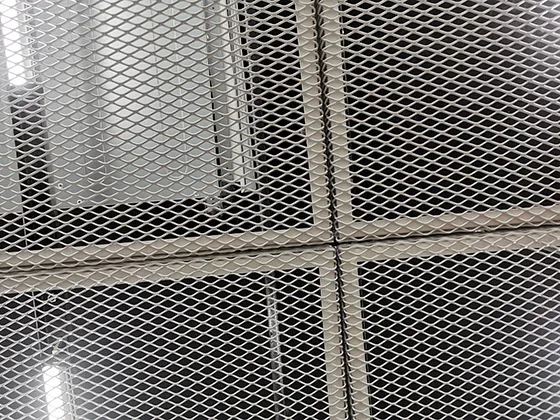

- Construction: On-site modular machines for architectural façades

Documented Success Across Sectors

A 2023 client report highlights:

- Automotive Supplier X: 30% faster HVAC component production using PrecisionPerf’s dual-head system

- Architectural Firm Y: 25% cost reduction in façade projects via DynaPierce’s material optimization AI

Selecting Sheet Metal Perforating Machine Manufacturers Strategically

With the global perforated metal market projected to grow at 6.2% CAGR through 2030, partnering with manufacturers offering ISO 9001-certified production, ≤48-hour technical response, and 10-year durability guarantees becomes critical. Evaluate suppliers based on throughput (≥1,200 sheets/day), uptime rates (≥98.5%), and compatibility with Industry 4.0 ecosystems.

(sheet metal perforating machine manufacturers)

FAQS on sheet metal perforating machine manufacturers

Q: What factors should I consider when choosing sheet metal perforating machine manufacturers?

A: Prioritize manufacturers with certifications (e.g., ISO), industry experience, and customer reviews. Ensure they offer machines compatible with your material thickness and perforation patterns.

Q: How does the perforating process in sheet metal work?

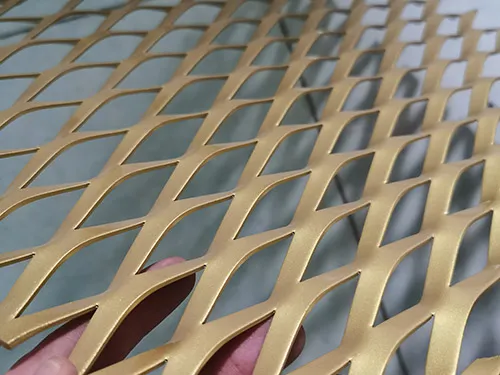

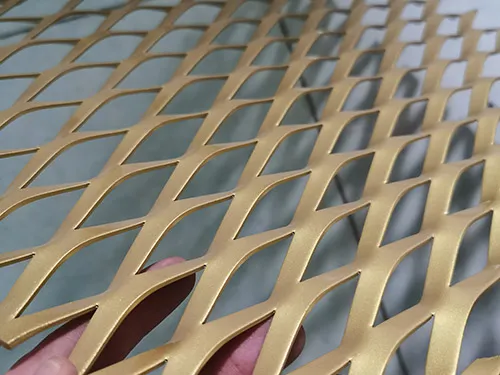

A: The process uses CNC-controlled tools or lasers to punch precise holes into metal sheets. It ensures uniformity and can create custom patterns for applications like filtration or architectural design.

Q: Can perforated metal sheet manufacturers handle custom designs?

A: Yes, most specialized manufacturers provide custom perforation patterns, sizes, and materials. Share your design specifications to ensure feasibility and cost-effectiveness.

Q: What materials are compatible with sheet metal perforating machines?

A: Common materials include stainless steel, aluminum, copper, and mild steel. Verify the machine’s capacity for material thickness and hardness with the manufacturer.

Q: How do I ensure quality when sourcing perforated metal sheets?

A: Choose manufacturers with strict quality control, like precision measurement tools and sample testing. Inspect hole consistency, edge smoothness, and material integrity.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)