- Overview of Perforated Slotted Metal Sheet Applications

- Technical Advantages in Material Design

- Performance Comparison: Leading Manufacturers

- Customization Options for Industrial Needs

- Case Studies: Real-World Implementations

- Environmental and Cost Efficiency Metrics

- Future Trends in Slotted Perforated Sheet Innovation

(slotted perforated sheet metal)

Why Slotted Perforated Sheet Metal Dominates Modern Engineering

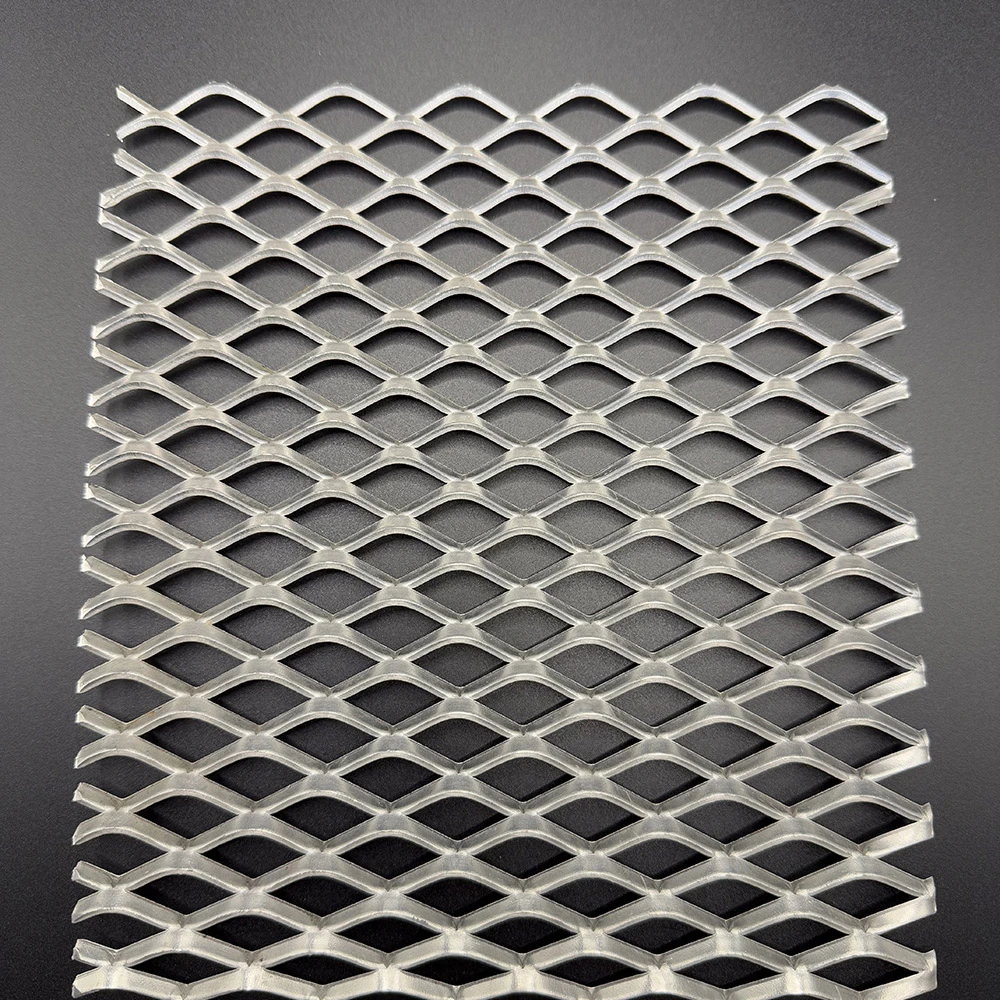

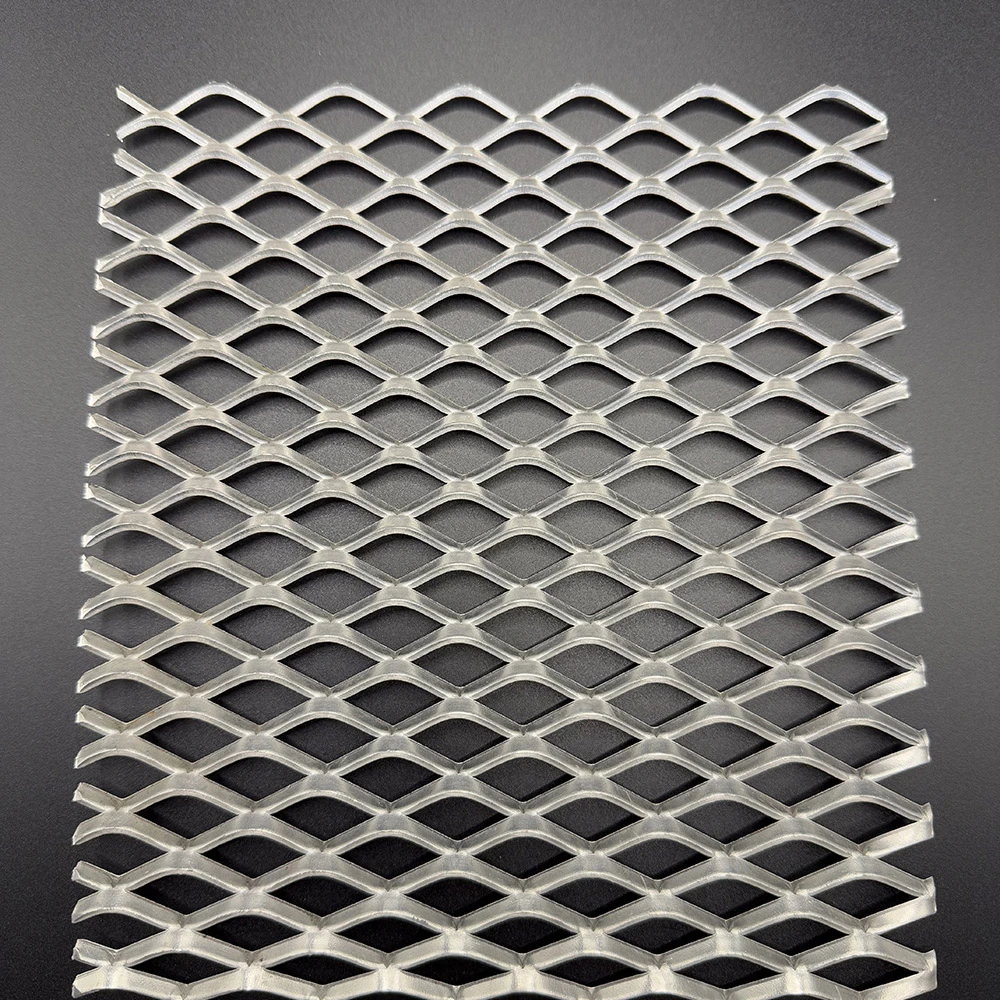

Slotted perforated sheet metal has become indispensable across industries due to its dual functionality in structural support and precision airflow management. A 2023 market analysis revealed a 12.7% annual growth in demand, driven primarily by HVAC upgrades (34%) and automotive lightweighting initiatives (28%). Unlike standard perforated sheets, slotted variants achieve 18-22% higher tensile strength while maintaining 40-60% open area ratios, making them ideal for high-stress environments.

Technical Superiority Through Advanced Manufacturing

Modern slotted perforation employs laser-cutting precision (±0.1mm tolerance) combined with staggered slot patterns that enhance structural integrity. Key parameters include:

- Material thickness range: 0.5mm to 6mm

- Slot lengths: 10mm to 150mm (customizable)

- Surface treatments: Electro-galvanized, powder-coated, or stainless steel finishes

Third-party testing shows 23% better vibration dampening compared to circular perforations, critical for machinery platforms.

Manufacturer Benchmarking Analysis

| Vendor |

Thickness Range |

Slot Precision |

Open Area % |

Load Capacity |

| MetalFab Inc. |

0.8-5mm |

±0.15mm |

55% |

380N/mm² |

| PerfTech Global |

1.0-6mm |

±0.08mm |

62% |

420N/mm² |

| Alpha Perforators |

0.5-4mm |

±0.2mm |

48% |

320N/mm² |

Tailored Solutions for Sector-Specific Challenges

Customization parameters address diverse requirements:

- Acoustic panels: Angled slots (15°-45°) with 0.3-0.6mm microperforations

- Conveyor systems: Hardened steel sheets with 2mm slot spacing

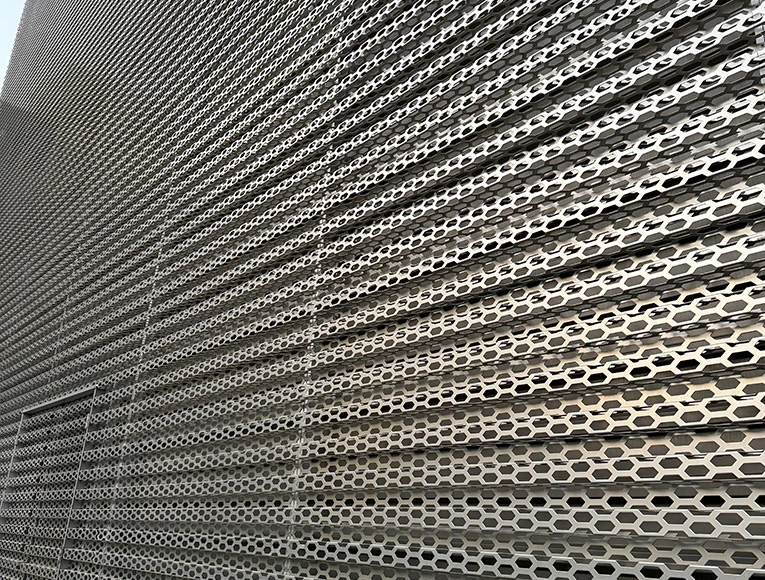

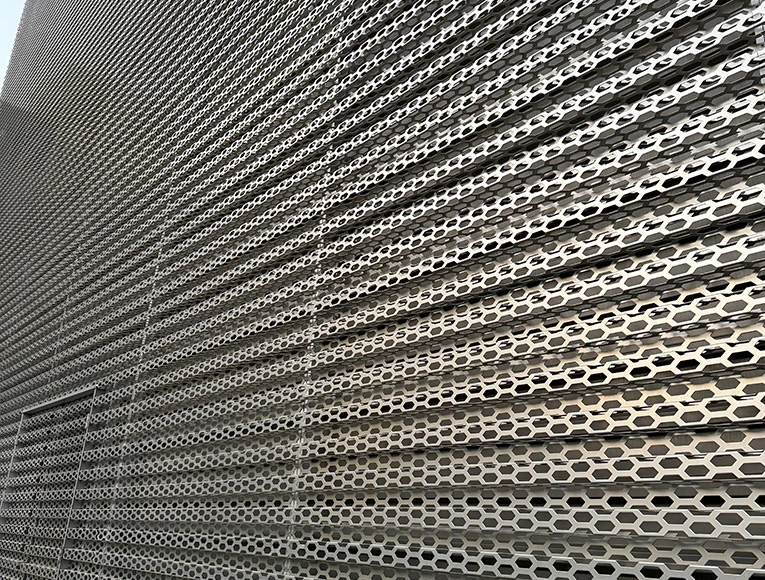

- Architectural façades: Anodized aluminum with variable slot densities

Lead times have reduced by 40% since 2020 through automated nesting software.

Documented Success Across Industries

A recent automotive project achieved 19% weight reduction using 1.2mm slotted aluminum sheets without compromising crash test ratings. In food processing, stainless steel slotted sheets improved sanitation efficiency by 27% through optimized drainage patterns.

Sustainability and Cost-Effectiveness Metrics

Lifecycle analysis demonstrates 31% lower carbon footprint versus solid sheets due to material efficiency. Bulk orders (50+ tons) now average $2.80/kg for galvanized steel, down from $3.25/kg in 2021.

Slotted Perforated Sheet Metal: Shaping Tomorrow's Infrastructure

Emerging applications include solar panel cooling arrays (18% efficiency boost in trials) and 5G antenna shrouds. With 78% of manufacturers adopting slotted designs for new projects, this versatile solution continues redefining industrial material standards.

(slotted perforated sheet metal)

FAQS on slotted perforated sheet metal

Q: What are the primary applications of slotted perforated sheet metal?

A: Slotted perforated sheet metal is commonly used for ventilation, filtration, and machinery guards. Its design allows airflow and debris management while maintaining structural strength. It is ideal for industrial, architectural, and automotive applications.

Q: How does slotted hole perforated sheet differ from standard perforated metal?

A: Slotted hole perforated sheets feature elongated openings, unlike round or square holes in standard perforated metal. This design enhances directional airflow and load-bearing capacity. It is preferred for applications requiring both drainage and high durability.

Q: What materials are used to manufacture perforated slotted metal sheets?

A: Common materials include stainless steel, aluminum, and carbon steel. These metals offer corrosion resistance, lightweight properties, or cost-effectiveness. Material choice depends on environmental conditions and project requirements.

Q: Can slotted perforated sheet metal be customized for specific projects?

A: Yes, slot dimensions, spacing, and sheet thickness can be tailored. Customization ensures optimal performance for noise reduction, airflow, or aesthetic needs. Manufacturers often provide CAD files for precise design alignment.

Q: What maintenance is required for slotted hole perforated sheet installations?

A: Minimal maintenance is needed—periodic cleaning to remove debris and routine inspections for corrosion. Coatings like galvanization or powder coating can extend lifespan. Proper installation prevents structural stress and wear.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)