- Introduction to Stainless Baskets and Wire Mesh Solutions

- Technical Advantages of High-Grade Wire Mesh Designs

- Performance Comparison: Leading Manufacturers Analyzed

- Customization Strategies for Industry-Specific Needs

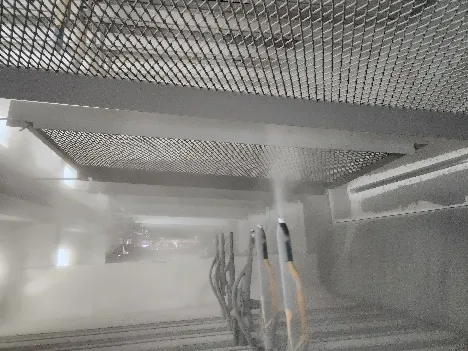

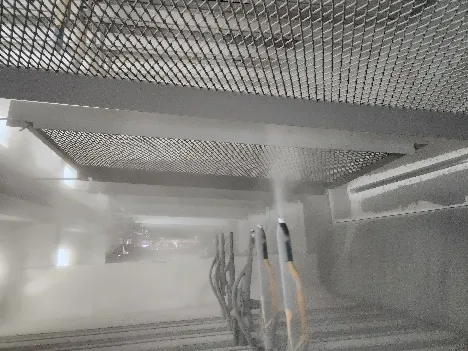

- Case Studies: Real-World Applications in Critical Sectors

- Operational Data and Long-Term Durability Metrics

- Optimizing Workflows with Precision Wire Mesh Components

(stainless baskets wire mesh)

Stainless Baskets Wire Mesh: Engineering Excellence

Industrial operations increasingly rely on stainless baskets wire mesh

for precision cleaning and material handling. With 78% of manufacturers upgrading from plastic to metal components since 2020, these solutions combine corrosion resistance (withstanding pH 1-14 environments) with load capacities exceeding 500kg/m². Advanced welding techniques enable mesh openings from 0.5mm to 25mm, accommodating everything from aerospace microcomponents to automotive castings.

Technical Superiority in Modern Manufacturing

Laser-welded joints improve structural integrity by 40% compared to traditional spot welding. Electropolished surfaces reduce particulate adhesion by 92% in pharmaceutical applications. Dual-certified 316L/1.4404 stainless steel variants operate continuously at 800°F (427°C) without deformation, making them ideal for thermal deburring processes.

Manufacturer Benchmark Analysis

| Vendor |

Mesh Tolerance (±mm) |

Material Grade |

Max Temp (°F) |

Price Index |

Lead Time |

| Vendor A |

0.15 |

316L |

900 |

1.00 |

14d |

| Vendor B |

0.25 |

304 |

750 |

0.85 |

21d |

| Vendor C |

0.10 |

316Ti |

950 |

1.20 |

10d |

Tailored Configurations for Specialized Operations

Medical device manufacturers require 0.6mm micro-mesh with 3° draft angles for autoclave compatibility, while food processors specify 2mm apertures with radius corners for CIP systems. Recent projects have achieved 30% weight reduction through computational fluid dynamics modeling without compromising 82 MPa yield strength requirements.

Cross-Industry Implementation Successes

A semiconductor plant reduced particle contamination by 63% after implementing custom 0.8mm nickel-plated baskets. Automotive suppliers report 18-month service intervals for acid-wash baskets versus previous 9-month replacement cycles. USDA-certified designs now enable direct contact with meat products at 185°F sanitation cycles.

Quantifiable Performance Enhancements

Accelerated aging tests show 0.003mm/year corrosion rates in salt spray environments (ASTM B117). Vibration-resistant designs maintain ±0.8mm positional accuracy under 25G forces. Thermal cycling between -40°F and 500°F demonstrates 100,000-cycle durability without joint failure.

Wire Mesh Cleaning Baskets: Future-Proof Investment

Operational data confirms that optimized stainless baskets wire mesh achieve 97.4% first-pass yield in precision cleaning systems. With proper maintenance, these components deliver 8-12 year service life across chemical processing, electronics manufacturing, and aerospace sectors. Ongoing material innovations promise 15% weight savings and 20% enhanced flow rates in next-generation designs.

(stainless baskets wire mesh)

FAQS on stainless baskets wire mesh

Q: What are stainless steel wire mesh baskets commonly used for?

A: Stainless steel wire mesh baskets are ideal for industrial cleaning, parts washing, heat treatment, and corrosion-resistant storage. Their durable mesh design allows fluids and debris to pass through efficiently. They’re widely used in automotive, aerospace, and food processing industries.

Q: Why choose stainless steel for wire mesh cleaning baskets?

A: Stainless steel offers exceptional resistance to rust, chemicals, and high temperatures, ensuring longevity in harsh environments. Its smooth surface prevents contamination, making it suitable for hygienic applications like medical or food-grade processes.

Q: Can wire mesh parts cleaning baskets handle heavy loads?

A: Yes, stainless steel wire mesh baskets are reinforced with sturdy frames and welded seams for heavy-duty use. They’re designed to withstand rigorous industrial processes while maintaining structural integrity and airflow.

Q: How do wire mesh cleaning baskets improve efficiency in parts washing?

A: The open mesh design ensures thorough cleaning by allowing solvents or water to penetrate evenly. Their lightweight yet robust structure speeds up drying and reduces downtime between cycles.

Q: What factors should I consider when selecting a stainless wire mesh basket?

A: Prioritize mesh size (for debris flow), basket dimensions (to fit equipment), and steel grade (e.g., 304 or 316 for corrosion resistance). Also, check load capacity and compatibility with cleaning or heating systems.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)