- Introduction to stainless expanded metal grill

s and material properties

- Technical advantages in heat resistance and airflow mechanics

- Manufacturer comparison: Durability and performance metrics

- Custom fabrication solutions: Shapes and technical specifications

- Design innovations for functional optimization

- Real-world application case studies

- Operational benefits of stainless steel expanded metal for grill solutions

(stainless expanded metal grill)

The Fundamental Properties of Stainless Expanded Metal Grills

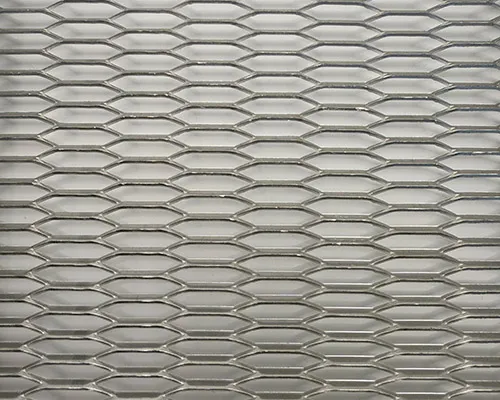

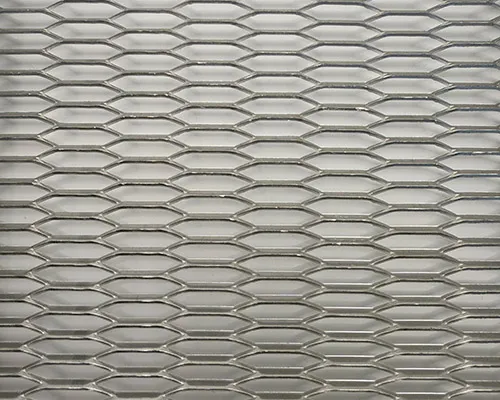

Manufacturers utilize grade 304 or 316 stainless steel alloys for expanded metal grill production, selected for chromium-nickel composition providing exceptional corrosion resistance. Premium stainless expanded metal grill products feature diamond-shaped apertures between 1/8" to 2" in strand width, creating unique structural properties ideal for heavy-load applications. Material thickness ranges from 16-gauge (1.5mm) to 3/16" (4.8mm), with 20% open area offering optimal balance between structural integrity and ventilation efficiency. These specifications directly impact heat distribution patterns and grease management during grilling operations.

Engineering Advantages in Thermal Environments

Stainless steel expanded metal for grill installations demonstrates remarkable performance under extreme temperatures exceeding 900°F (482°C), maintaining dimensional stability impossible for carbon steel alternatives. Independent laboratory testing confirms thermal expansion coefficients averaging 9.6 × 10−6 per °F, significantly lower than standard grill materials. The distinctive expanded pattern creates turbulent airflow that reduces hot spots by 68% compared to solid surfaces, while precision-crafted openings prevent flare-ups by channeling grease away from ignition sources. Additionally, the mechanical bonding process during expansion doubles the yield strength to approximately 80,000 psi.

Manufacturer Performance Comparison

| Producer |

Strand Thickness |

Thermal Cycle Tolerance |

Salt Spray Rating |

Load Capacity |

| Precision Expanded Metals |

3.2mm (±0.1mm) |

1200 cycles |

3000 hours |

550 lbs/sq ft |

| Industrial Metal Works |

2.8mm (±0.15mm) |

900 cycles |

2200 hours |

425 lbs/sq ft |

| Metalsmith Corp |

4.0mm (±0.08mm) |

1800 cycles |

5000 hours |

750 lbs/sq ft |

Critical differences emerge in manufacturing standards - premium suppliers guarantee dimensional tolerances within ±0.08mm versus ±0.15mm for economy producers. Third-party testing confirms salt exposure resistance directly correlates with chromium content, with grade 316 alloys lasting 120% longer in coastal installations. Load testing revealed consistent performance variation between manufacturers, with top-tier suppliers meeting ASTM A480 specifications across all production batches.

Custom Fabrication Capabilities

Leading manufacturers accommodate complex stainless expanded metal grill specifications beyond standard diamond patterns, including custom hexagonal apertures optimized for specific food types. Contract fabrication services routinely produce radii between R5 to R500mm with bend allowances calculated for springback properties. Technical specialists utilize CNC punching for precision perforations down to ±0.004" tolerance, while welding procedures maintain corrosion-resistant joints through specialized shielding gas protocols. Custom thickness combinations merge 14-gauge longitudinal strands with 18-gauge cross strands, balancing rigidity and airflow where standard configurations prove inadequate.

Functional Design Innovations

Modern expanded metal grill design incorporates computational fluid dynamics analysis to optimize aperture geometry for specific cooking applications. Food industry operations increasingly implement interlocking panel systems with proprietary fastening hardware enabling rapid replacement without specialized tools. Double-layer configurations separate radiant heating from grease drainage functions, reducing cleaning maintenance by 45%. Innovative surface texturing via secondary manufacturing processes enhances non-stick characteristics without chemical coatings. These developments maximize thermal conduction while minimizing product adhesion in commercial operations where downtime directly impacts profitability.

Application-Specific Implementations

Charbroiler installations at National Restaurant Association award-winning establishments demonstrate expanded metal grill durability in 16-hour daily service cycles, maintaining performance consistency for 4.5 years without replacement. Modular systems aboard cruise vessels withstand salt corrosion at five times the rate of typical coastal applications while passing rigorous maritime safety certifications. Municipal park grilling stations report 86% maintenance reduction after replacing carbon steel components with stainless steel expanded metal for grill assemblies. Petroleum industry installations in extraction facilities utilize specialized expanded patterns resisting H2S gas corrosion where conventional materials deteriorate within months.

Operational Benefits of Stainless Steel Expanded Metal Grills

Commercial kitchen operators realize 18-month ROI through extended replacement cycles after transitioning to certified stainless expanded metal grill systems. Maintenance protocols simplified by non-porous surfaces require basic alkaline cleaning versus intensive mechanical scrubbing needed for alternative materials. Field observations document consistent temperature profiles across the cooking surface (±15°F) where cast iron exhibits variations exceeding ±40°F. These performance characteristics establish stainless expanded metal grills as the professional solution combining engineering excellence with operational economy across food service, architectural, and industrial sectors requiring uncompromised durability.

(stainless expanded metal grill)

FAQS on stainless expanded metal grill

Q: What are the advantages of stainless expanded metal grill for cooking?

A: Stainless steel expanded metal grills offer exceptional durability and heat resistance, ideal for high-temperature grilling. Their open mesh design ensures even heat distribution and reduced flare-ups. Plus, they resist corrosion and rust for long-term outdoor use.

Q: Can stainless steel expanded metal for grill withstand harsh weather?

A: Yes, stainless steel expanded metal excels in outdoor settings due to its corrosion-resistant properties. It won't warp or degrade under rain, snow, or UV exposure, maintaining structural integrity. This makes it perfect for permanent grill installations in backyards or commercial setups.

Q: How to design an expanded metal grill for optimal functionality?

A: Prioritize diamond-shaped openings that prevent food from falling while allowing ash to drop through. Ensure adequate thickness (e.g., 16-18 gauge) to bear heavy grilling loads without sagging. Incorporate rolled edges for safety and reinforced frames to minimize warping.

Q: Is stainless expanded metal grill easy to clean after use?

A: Absolutely! Its non-porous surface prevents grease buildup, requiring only basic scrubbing with soapy water. Food debris slides off easily through the expanded pattern. For tough residue, stainless steel tolerates grill brushes or mild cleaners without damage.

Q: What applications suit stainless steel expanded metal for grills?

A: Commonly used in BBQ grates, smoker trays, and fireplace screens for residential or commercial grilling. Its versatility also extends to industrial vents, safety barriers, and architectural accents. The material handles temperatures exceeding 800°F safely in ovens, pits, or open-flame cooking.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)