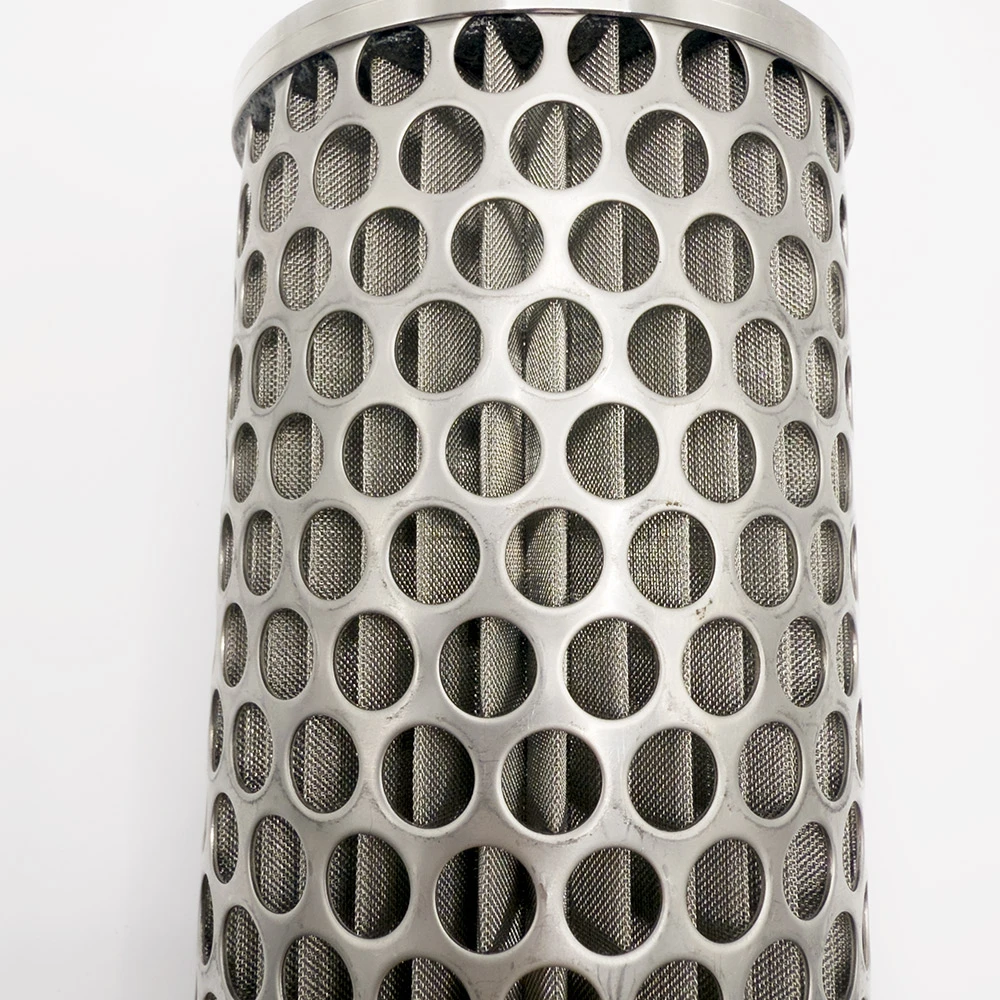

As a leading manufacturer in the metal mesh industry, Anping Chen Cai Metal Manufacture Co. Ltd. offers cutting-edge stainless steel industrial filtration elements designed to meet the rigorous demands of modern manufacturing processes. These high-performance filtration solutions are engineered to deliver exceptional durability, precision, and reliability across diverse industrial applications. Explore how our stainless steel filter cartridges and sintered stainless steel filter cartridges can revolutionize your filtration systems.

Our stainless steel industrial filtration elements are meticulously crafted to provide superior filtration efficiency and long-term performance. These elements are available in various configurations, including stainless steel filter cartridges, stainless steel filter elements, and sintered stainless steel filter cartridges, each tailored to specific industrial requirements. The advanced design ensures optimal flow rates while maintaining high filtration accuracy, making them ideal for applications in chemical processing, pharmaceuticals, food and beverage, and more.

Our stainless steel filtration elements are widely used in the following sectors:

With over a decade of experience in the metal mesh and filtration industry, Anping Chen Cai Metal Manufacture Co. Ltd. has established itself as a trusted supplier of high-quality stainless steel filtration solutions. Our commitment to innovation, quality control, and customer satisfaction ensures that every product meets the highest industry standards. We offer:

Compared to traditional filtration materials, stainless steel elements offer several advantages:

Our clients consistently praise the performance and reliability of our stainless steel filtration elements. For example:

"After switching to Anping Chen Cai's stainless steel filter cartridges, our production efficiency increased by 30%. The precision and durability of their products have significantly reduced maintenance costs." - John Doe, Operations Manager at XYZ Chemicals

Another customer shared: "The sintered stainless steel filter cartridges we purchased from Anping Chen Cai have exceeded our expectations. They are perfect for our pharmaceutical applications, ensuring a sterile environment at all times." - Emily Smith, Quality Control Lead at ABC Pharmaceuticals

To maximize the performance of your stainless steel filtration elements, follow these guidelines:

Q: What are the main benefits of using stainless steel filtration elements?

A: Stainless steel elements offer excellent corrosion resistance, high filtration accuracy, and long service life, making them ideal for harsh industrial environments.

Q: Can these filtration elements be customized for specific applications?

A: Yes, we provide tailored solutions to meet unique filtration requirements, including custom sizes, grades, and configurations.

Q: How do I choose the right filtration precision for my application?

A: The required precision depends on the type of contaminants and the industry standards. Our technical team can assist you in selecting the optimal specification.

Stainless steel industrial filtration elements from Anping Chen Cai Metal Manufacture Co. Ltd. are a reliable and cost-effective solution for industries seeking high-performance filtration. With their durability, precision, and adaptability, these elements help businesses improve operational efficiency and reduce maintenance costs. Discover the difference of professional-grade stainless steel filtration today!

For more information or to place an order, contact Anping Chen Cai Metal Manufacture Co. Ltd. directly:

PREV:

This is the last article