|

Item

|

Description

|

|

Product Name

|

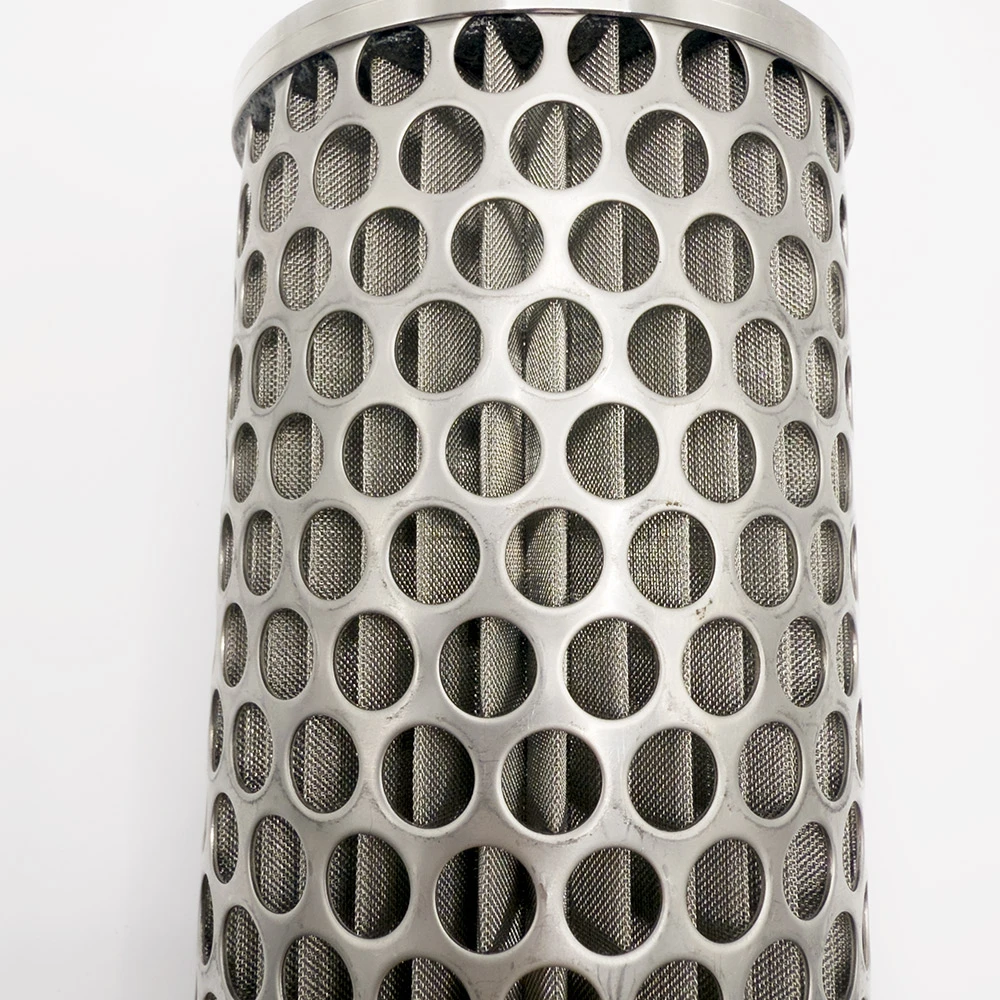

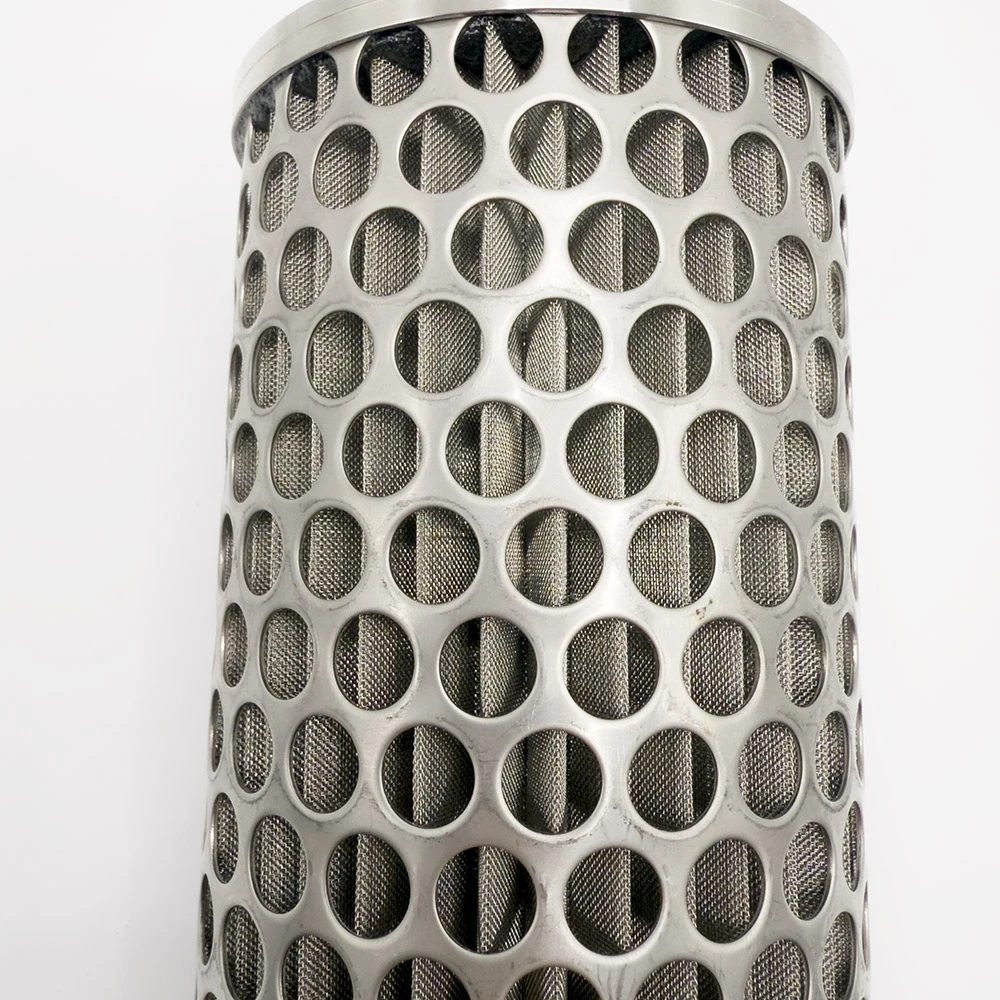

Stainless Steel Industrial Filtration Element

|

|

Material

|

Stainless Steel (304, 316L), Nickel Alloy (Monel, Hastelloy), Titanium Alloy

|

|

Outer Diameter

|

10mm - 600mm (Customizable)

|

| Wall Thickness |

0.3mm - 5mm (Customizable)

|

|

Perforation Size

|

0.3mm - 10mm (Round, Square, Slotted Holes Available)

|

|

Open Area

|

10% - 60% (Customizable Based on Filtration Needs)

|

|

Example of Filtration Precision (μm)

|

|

Aperture Size (mm)

|

Filtration Precision (μm)

|

Application

|

|

5.0

|

5000

|

large particle removal

|

|

2.0

|

2000

|

suitable for large debris removal

|

|

1.0

|

1000

|

removing larger solid impurities

|

|

0.5

|

500

|

capturing liquid particles

|

|

0.1

|

100

|

Ultra-fine filtration

|

|

For higher precision filtration (1-50μm), an additional fine filter bag or inner lining can be integrated with the stainless steel perforated mesh to achieve superior performance.

Would you like a recommendation for the optimal aperture size and material based on your application? Let me know your required filtration standard (μm)!

|

|

|

Surface Treatment

|

1. Pickling(Stainless steel (304, 316L), carbon steel, nickel-based alloy (Monel, Hastelloy)

2. Electrolytic Polishing(Stainless steel (304, 316L), nickel-based alloy (Monel, Hastelloy))

3. Sandblasting (Iron, carbon steel, stainless steel (304, 316L), titanium alloy, nickel-based alloy (Monel, Hastelloy))

4. Galvanizing(Iron, carbon steel)

5. Nickel Plating(Iron, carbon steel, stainless steel (304, 316L), nickel-based alloys (Monel, Hastelloy))

etc.

|

|

Welding Type

|

Spiral Welding / Seam Welding (Ensures High Strength and Sealing Performance)

|

|

Pressure Resistance

|

Up to 30MPa (Adjustable Based on Material & Thickness)

|

|

Corrosion Resistance

|

Acid and Alkali Resistant, High-Temperature Resistant, Oxidation Resistant

|

|

Connection Type

|

Flange Connection, Threaded Connection, Welded Connection, Clamping Type

|

|

Applicable Fluids

|

Liquids, Gases, Oils, Steam, etc.

|

|

Cleaning Method

|

Backwashing, Chemical Cleaning, Ultrasonic Cleaning, High-Temperature Baking

|

|

Application Fields

|

Petrochemical, Natural Gas, Environmental Water Treatment, Food & Pharmaceutical, Metallurgy, Power Industry, Automotive Industry, etc.

|

|

Product Features

|

1. High-strength structure, resistant to high pressure and corrosion

2. Uniform perforation for optimal airflow and filtration efficiency

3. Precision welding technology ensures durability

4. Customizable materials, hole sizes, and porosity to meet specific filtration needs

|

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)