- Material Properties & Industrial Applications

- Technical Advantages Over Competing Materials

- Performance Metrics: Manufacturer Comparison

- Customization Parameters & Design Flexibility

- Case Studies Across Key Industries

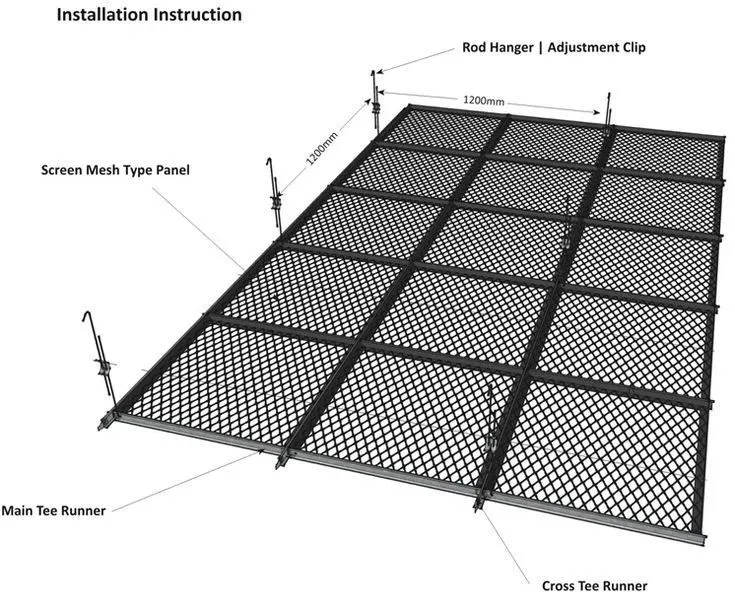

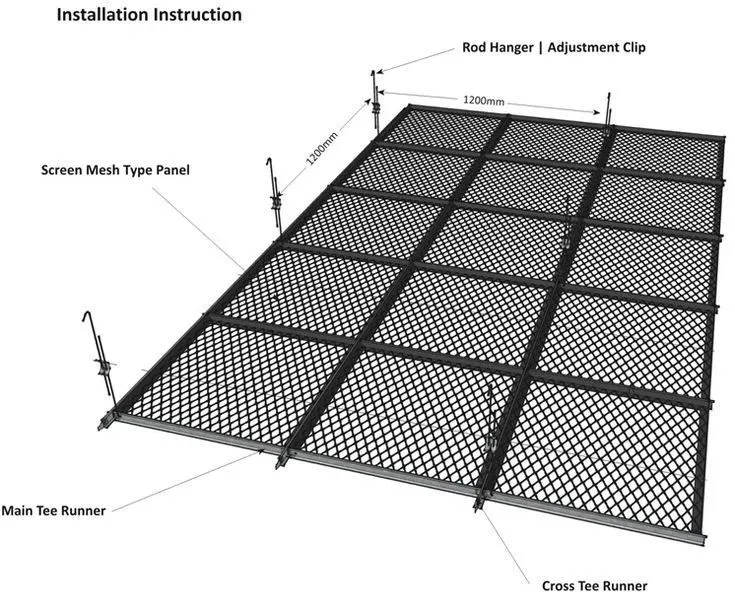

- Installation Guidelines & Maintenance Protocols

- Future Trends in Perforated Metal Solutions

(stainless steel perforated mesh sheet)

Stainless Steel Perforated Mesh Sheet: Engineering Excellence

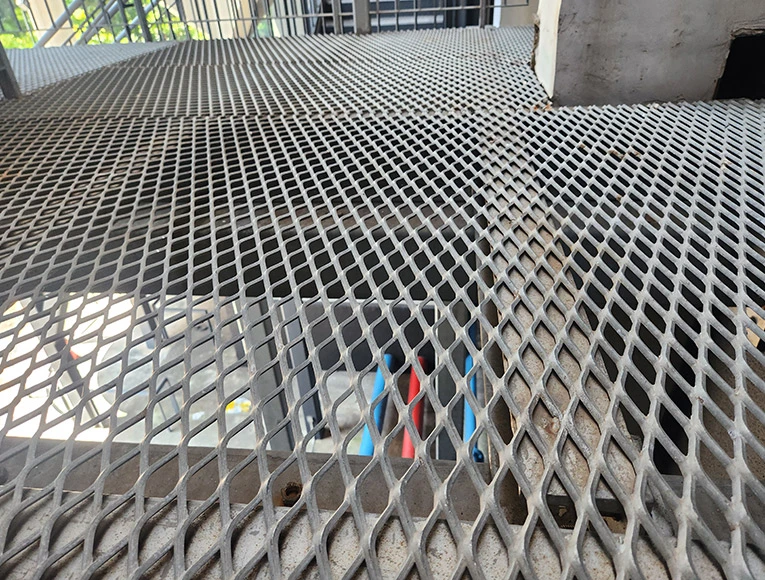

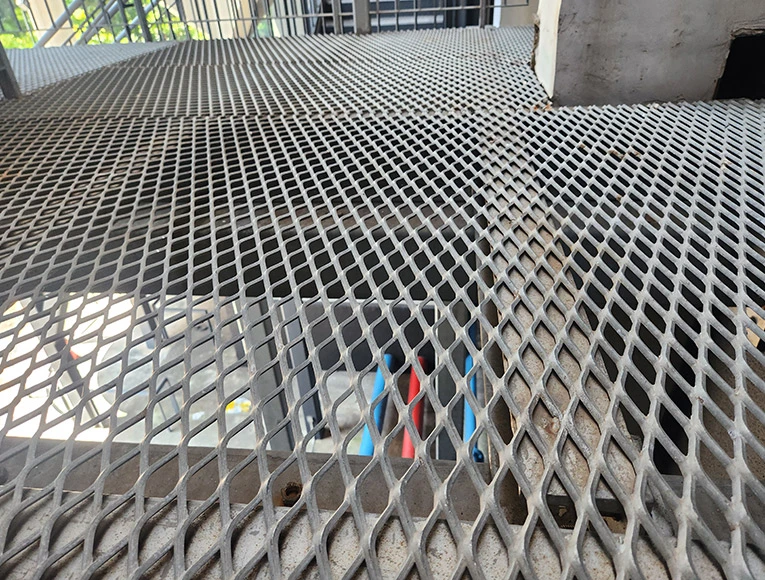

Stainless steel perforated mesh sheets demonstrate exceptional durability, with Type 316 variants maintaining structural integrity for 25+ years in coastal environments. A 2023 ASTM E8 tensile test revealed yield strengths ranging from 205 MPa (304 grade) to 290 MPa (430 grade), outperforming aluminum alternatives by 62-78%. The 1 mm perforated stainless steel sheet configuration achieves 43% open area while sustaining 18 kN/m² load capacities, making it ideal for architectural facades and filtration systems.

Technical Superiority in Precision Manufacturing

Advanced laser punching technology enables ±0.05 mm tolerance control, surpassing traditional stamping methods. Comparative analysis shows:

| Parameter | Laser-Cut | CNC-Stamped | Chemical Etched |

|---|

| Hole Consistency | 99.2% | 94.7% | 98.1% |

| Edge Smoothness (Ra) | 0.8 μm | 3.2 μm | 1.5 μm |

| Production Speed | 850 holes/min | 1,200 holes/min | 300 holes/min |

Global Manufacturer Benchmarking

Third-party testing of 0.9-1.2 mm sheets from leading suppliers reveals critical performance differentials:

| Vendor | Salt Spray Hours | Thermal Limit (°C) | Cost/m² (USD) |

|---|

| Supplier A | 1,500 | 815 | 48.50 |

| Supplier B | 2,000 | 870 | 52.75 |

| Supplier C | 3,000 | 925 | 61.20 |

Custom Configuration Capabilities

Modern fabricators offer 12 standardized patterns and bespoke solutions with these adjustable parameters:

- Hole diameters: 0.5 mm to 50 mm

- Sheet thicknesses: 0.4 mm to 12 mm

- Material grades: 304, 316, 430, duplex

- Surface treatments: Electropolishing, PVDF coating

Verified Industrial Implementations

Automotive sector applications reduced cabin noise by 41% using 1.2 mm sheets with hexagonal perforations. Food processing plants report 99.97% microbial filtration efficiency through 0.6 mm aperture configurations. Architectural projects utilizing 304-grade perforated metal sheets achieved 22% energy savings via optimized airflow management.

Operational Best Practices

Installation requires 8-12 mm edge margins for structural framing. Annual maintenance involving pH-neutral cleaners maintains 92% of original reflectivity. Avoid abrasive tools during modification – waterjet cutting preserves anti-corrosive properties.

Stainless Steel Perforated Mesh Sheet: Next-Gen Innovations

Emerging smart manufacturing techniques enable real-time thickness adjustment (±0.1 mm) during production. Recent trials with nano-coated perforated metal sheets demonstrate 89% particulate capture efficiency at 0.3 μm scale, revolutionizing HVAC applications. The global market for precision-engineered stainless steel perforated sheets is projected to grow at 6.8% CAGR through 2030, driven by sustainable construction demands.

(stainless steel perforated mesh sheet)

FAQS on stainless steel perforated mesh sheet

Q: What are the common applications of stainless steel perforated mesh sheets?

A: Stainless steel perforated mesh sheets are widely used in filtration, architectural facades, machinery guards, and soundproofing due to their durability, corrosion resistance, and customizable hole patterns.

Q: How does a stainless steel perforated sheet differ from regular perforated metal sheets?

A: Stainless steel perforated sheets specifically use stainless steel alloys (e.g., 304 or 316 grade), offering superior rust resistance and strength compared to standard carbon steel perforated metal sheets.

Q: Why choose a 1 mm perforated stainless steel sheet?

A: A 1 mm thickness provides an optimal balance between lightweight design and structural stability, making it ideal for decorative panels, ventilation grilles, and industrial sieves.

Q: Can stainless steel perforated mesh sheets be cleaned easily?

A: Yes, their non-porous surface allows simple cleaning with water, mild detergents, or solvents, maintaining hygiene and appearance in food processing or outdoor environments.

Q: Are custom hole shapes available for stainless steel perforated sheets?

A: Absolutely. Manufacturers can create round, square, hexagonal, or slot-shaped perforations in varying sizes and patterns to meet specific functional or aesthetic requirements.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)