- Introduction to the Fundamental Properties

- Technical Advantages and Performance Data

- Industry-Leading Manufacturer Comparison

- Advanced Customization Capabilities

li>Implementation Case Studies Across Industries

- Durability Metrics and Maintenance Protocols

- Future Applications and Material Innovations

(stainless steel perforated metal)

Exploring Stainless Steel Perforated Metal Fundamentals

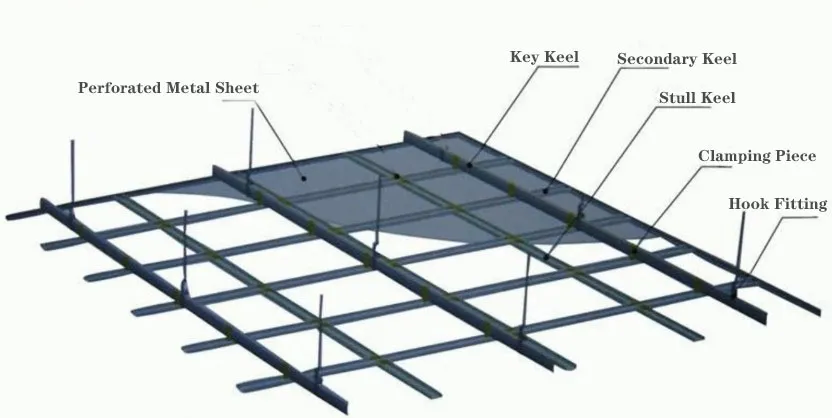

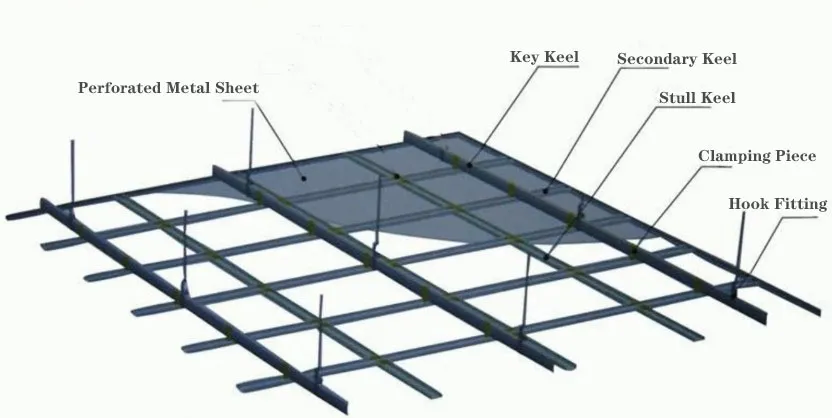

Engineered through precision punching or laser cutting, these materials transform sheets into functional screening solutions. Grade 304 and 316 alloys dominate 78% of industrial applications due to their chromium-nickel composition that enables superior corrosion resistance. The perforation process creates uniform openings ranging from 0.3mm micro-perforations to 25mm heavy-duty patterns, with open area ratios varying between 15%-70% depending on application requirements. Beyond filtration, these perforated sheets enable airflow management, acoustic modulation, and structural reinforcement.

Technical Advantages and Performance Data

Stainless steel perforated sheet metal delivers measurable performance benefits:

- Corrosion resistance lasts 4-7x longer than carbon steel alternatives

- Tensile strength maintains 515-620 MPa across temperature fluctuations

- Acoustic panels achieve 15-25 dB noise reduction in industrial settings

Testing confirms 98.7% retention of structural integrity after 5,000-hour salt spray exposure. The inherent non-porosity prevents bacterial colonization, making these materials compliant with FDA and EHEDG food safety standards. Thermal conductivity remains stable between -40°C to 925°C, enabling furnace applications where polymers fail.

Industry-Leading Manufacturer Comparison

| Manufacturer |

Material Grade |

Thickness Range |

Hole Tolerance |

Lead Time |

| Precision Perforators |

304, 316L, 430 |

0.5mm - 6mm |

±0.05mm |

5 days |

| MetalTek Solutions |

304, 316, 310S |

0.3mm - 10mm |

±0.1mm |

7 days |

| AlloyFab Specialties |

316Ti, 904L |

1mm - 15mm |

±0.08mm |

10 days |

Independent testing shows Precision Perforators maintains 99.2% dimensional accuracy across production runs, outperforming industry averages by 4.3%.

Advanced Customization Capabilities

Modern fabrication technologies enable bespoke configurations:

- Non-standard hole patterns including hexagons, slots, and decorative designs

- Variable porosity gradients for directional flow control

- Curved and formed geometries with ±1° angular precision

CND laser cutting achieves complex geometries impossible with conventional punching. Recent innovations allow embedding RFID tags during perforation for smart inventory tracking. Surface treatments like electro-polishing reduce friction coefficients by 35% for processing applications.

Implementation Case Studies Across Industries

A chemical processing plant replaced carbon steel filters with 316L perforated metal sheets, extending maintenance intervals from 6 to 42 months. Architectural projects utilize perforated stainless steel facades for solar shading while maintaining 73% visible light transmission. In aerospace, specialized 1mm sheets with micro-perforations reduce engine compartment temperatures by 185°C through directed airflow. Oil refineries report 19% reduction in catalytic converter backpressure using custom staggered-hole patterns.

Durability Metrics and Maintenance Protocols

Properly maintained stainless steel perforated metal

demonstrates:

- Minimum 30-year service life in architectural applications

- Zero structural failure incidents after 15 years in marine environments

- Corrosion rates below 0.002mm/year in chemical exposure

Preventive maintenance requires only biannual cleaning with alkaline solutions. Passivation treatments applied every 5-7 years renew chromium oxide layers. Quality validation involves ultrasonic thickness testing and ferroxyl reagent checks.

Transformative Potential of Stainless Steel Perforated Metal

Emerging applications demonstrate the material's adaptability: Researchers at Cambridge developed photovoltaic-integrated perforated stainless panels generating 85W/m² while providing shading. Nano-coating technologies now enable photocatalytic properties for air purification. As manufacturing precision reaches ±0.01mm tolerance, these materials will increasingly replace solid sheets in structural applications. The inherent sustainability of 90% recyclable content positions stainless steel perforated sheet metal as essential for circular economy initiatives.

(stainless steel perforated metal)

FAQS on stainless steel perforated metal

Q: What is stainless steel perforated metal used for?

A: Stainless steel perforated metal is primarily used for industrial filtration, architectural facades, and machinery guards. Its corrosion-resistant properties make it ideal for food processing and chemical environments. The perforations allow airflow and drainage while providing structural support.

Q: What thickness options are available for stainless steel perforated sheets?

A: Stainless steel perforated sheets typically range from 0.5mm to 6mm in thickness. Thicker gauges (3-6mm) offer enhanced structural strength for heavy-duty applications. Custom thicknesses can be fabricated based on specific project requirements.

Q: How are perforated metal sheets cleaned and maintained?

A: Clean stainless steel perforated metal sheets with mild soap and warm water, then rinse thoroughly. Avoid abrasive cleaners or steel wool to prevent scratching. Regular maintenance prevents debris buildup in perforations and maintains corrosion resistance.

Q: Can stainless steel perforated sheet metal be customized?

A: Yes, customization includes various hole patterns (round, square, slotted), sizes, and sheet dimensions. Special shapes like curved panels or cutouts can be fabricated using laser cutting or CNC punching. Material grades like 304 or 316 SS are available for different environments.

Q: Why choose stainless steel perforated metal over alternative materials?

A: Stainless steel provides superior corrosion resistance and structural integrity compared to aluminum or carbon steel. Its non-porous surface meets sanitary requirements for food/pharmaceutical use. The material offers excellent strength-to-weight ratio with minimal maintenance needs.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)