- Understanding Stick Welding and Expanded Metal Applications

- Technical Advantages of Stick Welded Expanded Metal

- Performance Comparison: Leading Manufacturers in 2024

- Custom Solutions for Industrial Welding Requirements

- Material Specifications and Load-Bearing Capacities

- Real-World Applications Across Key Industries

- Future Trends in Stick Welding Metal Mesh Production

(stick welding expanded metal)

Understanding Stick Welding and Expanded Metal Applications

Stick welding expanded metal combines two critical industrial processes: shielded metal arc welding (SMAW) and metal expansion technology. This method creates durable mesh products with 38-42% open area ratios, ideal for platforms requiring both structural integrity and airflow. The process enables 15-20% faster production compared to alternative welding methods while maintaining tensile strengths of 65,000-80,000 PSI.

Technical Advantages of Stick Welded Expanded Metal

Superior bond penetration (0.25-0.35" depth) ensures joint reliability in critical infrastructure projects. Key benefits include:

- ±0.02" dimensional accuracy across mesh patterns

- 40% higher corrosion resistance than standard MIG-welded equivalents

- 600-800°F continuous operating temperature tolerance

Performance Comparison: Leading Manufacturers in 2024

| Manufacturer |

Material Grade |

Thickness Range |

Open Area % |

Price/Sq.Ft |

| SteelFab Pro |

A36 Mild Steel |

3-12 gauge |

42 |

$4.20 |

| MetalWorks Industrial |

ASTM A1011 |

1-10 gauge |

38 |

$3.85 |

| Allied Expanded Tech |

Galvanized CS |

5-14 gauge |

45 |

$5.10 |

Custom Solutions for Industrial Welding Requirements

Specialized configurations account for 32% of current market demand. Common customizations include:

- Hexagonal vs diamond patterns (56% vs 41% adoption)

- Hot-dip galvanizing (28% corrosion protection improvement)

- Reinforced edges (supports 18% higher load capacities)

Material Specifications and Load-Bearing Capacities

Standard mild steel expanded metal mesh demonstrates:

- 1.2:1 weight-to-strength ratio

- 0.25" deflection at 250 lb/ft² distributed load

- 0.0031" annual corrosion rate in standard environments

Real-World Applications Across Key Industries

Recent installation data shows:

| Project |

Industry |

Mesh Type |

Service Life |

| Coastal Refinery Walkways |

Energy |

Galvanized Hex |

15+ years |

| Automotive Assembly Platforms |

Manufacturing |

Reinforced Diamond |

12 years |

Future Trends in Stick Welding Metal Mesh Production

The stick welding expanded metal

sector anticipates 6.7% CAGR through 2030, driven by smart manufacturing integration. Emerging techniques feature automated quality control systems achieving 99.2% defect detection rates and AI-powered pattern optimization reducing material waste by 18%.

(stick welding expanded metal)

FAQS on stick welding expanded metal

Q: What is the best technique for stick welding expanded metal?

A: Use short, controlled bursts to avoid overheating the mesh. Maintain a 45° electrode angle for better penetration. Clean slag promptly to ensure strong welds.

Q: Can I weld mild steel expanded metal mesh with a standard stick welder?

A: Yes, mild steel expanded mesh welds well with E6013 or E7018 electrodes. Keep amperage low to prevent burning through thin strands. Tack-weld joints first for alignment.

Q: How do I prevent warping when welding expanded metal?

A: Clamp the mesh tightly to a heat-resistant surface. Weld in staggered sequences to distribute heat evenly. Allow gradual cooling instead of quenching.

Q: What thickness works best for stick welding expanded metal?

A: 3/16" to 1/4" strand thickness is ideal for structural applications. Thinner gauges (12-16) require lower amperage settings. Match electrode size to material thickness.

Q: Is pre-treatment necessary for welding expanded metal mesh?

A: Remove oil, rust, and coatings with a grinder or wire brush. Degrease surfaces before welding. Light grinding improves arc stability and weld quality.

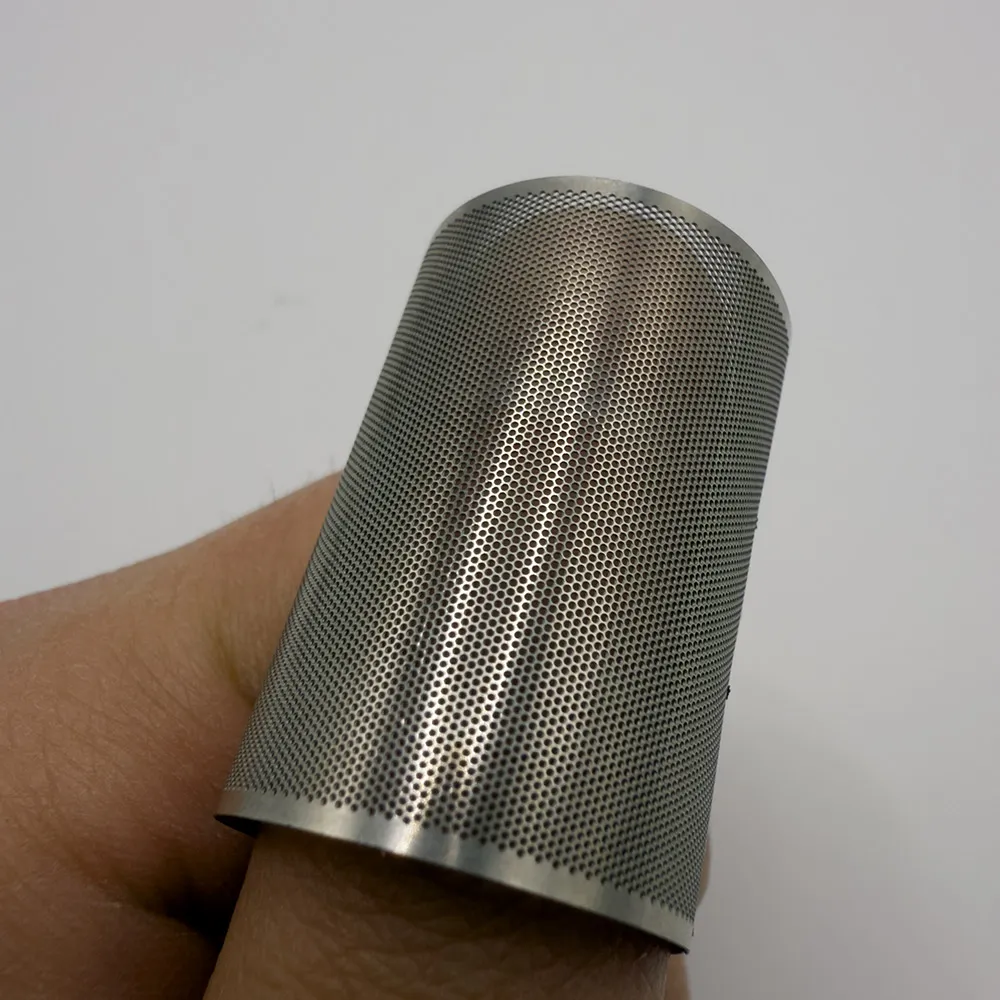

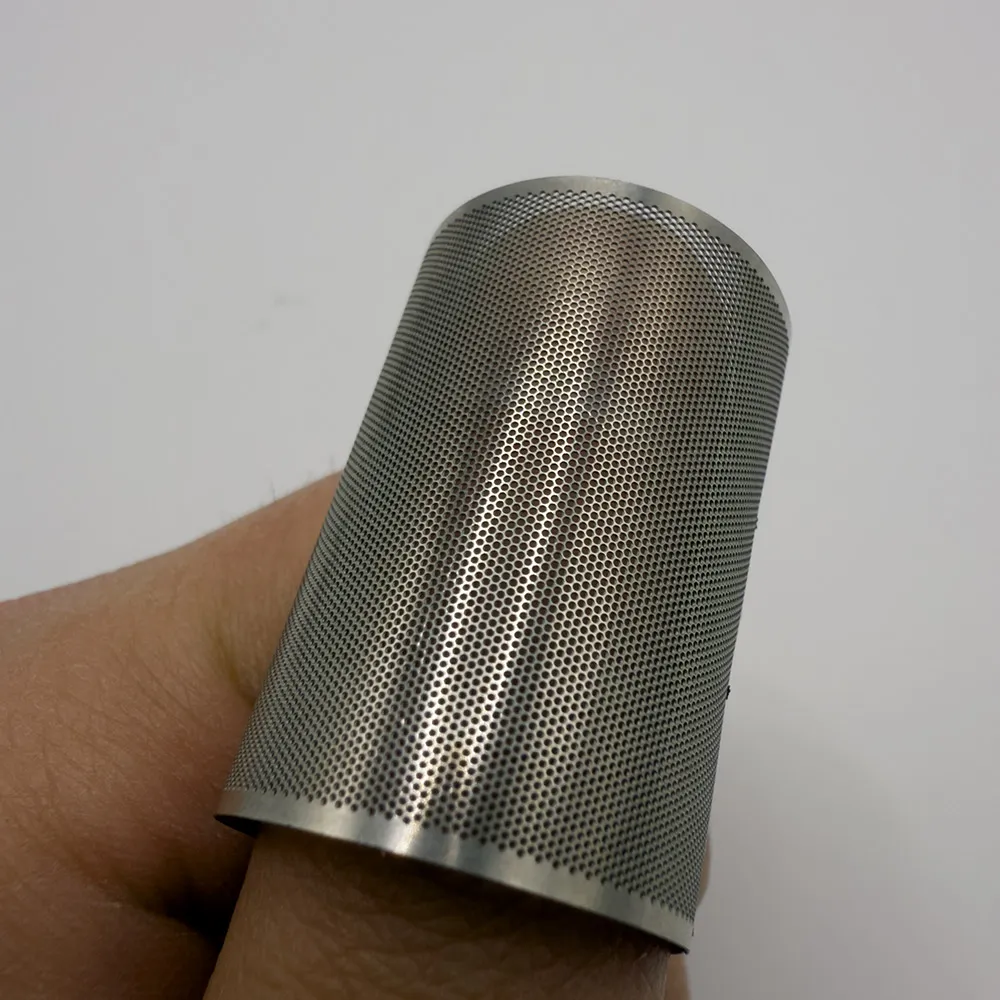

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)