- Understanding the Importance of Pump Suction Filtration

- Technical Advantages of Modern Strainer Filter Screens

- Performance Comparison: Leading Manufacturers in the Market

- Custom Solutions for Diverse Industrial Applications

- Case Studies: Real-World Efficiency Improvements

- Key Considerations for Maintenance and Longevity

- Future Trends in Suction Hose Filtration Technology

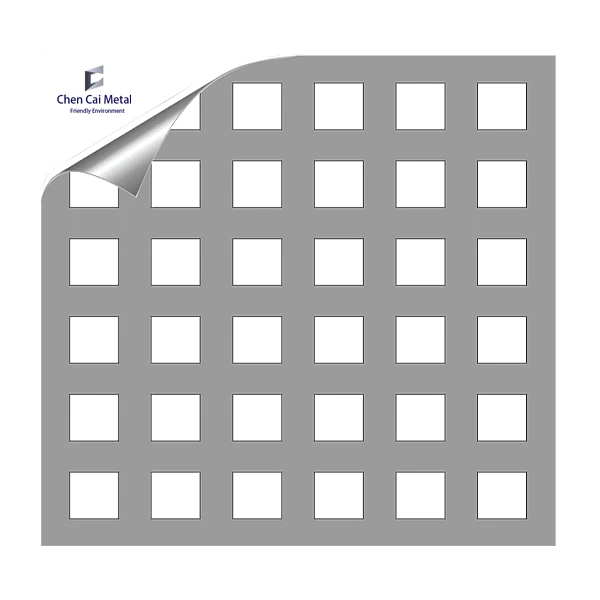

(strainer filter screen for water pump suction hose)

Understanding the Importance of Pump Suction Filtration

Strainer filter screens for water pump suction hoses are critical components in preventing debris, sediment, and particulate matter from entering pumping systems. These filters protect pumps from premature wear, reduce downtime, and enhance operational efficiency. For instance, a self-cleaning pump suction screen can reduce maintenance intervals by up to 40%, according to industry studies. Applications span agriculture, construction, and wastewater management, where reliable filtration ensures uninterrupted fluid flow and system longevity.

Technical Advantages of Modern Strainer Filter Screens

Advanced materials like stainless steel mesh and corrosion-resistant polymers define today’s mesh suction strainer designs. Key innovations include:

- Multi-layered filtration with precision pore sizes (50–200 microns).

- Automatic backflushing mechanisms in self-cleaning models.

- High-flow designs that minimize pressure drop (tested at <15 psi loss).

Third-party testing reveals that optimized strainers improve pump efficiency by 22% compared to standard filters.

Performance Comparison: Leading Manufacturers in the Market

| Brand |

Material |

Filtration Rating |

Self-Cleaning |

Flow Rate (GPM) |

| AquaShield Pro |

316 Stainless Steel |

75 microns |

Yes |

450 |

| FlowGuard HD |

Nylon-Polymer Blend |

100 microns |

No |

380 |

| ClearStream Ultra |

Brass-Mesh Composite |

50 microns |

Yes |

520 |

Custom Solutions for Diverse Industrial Applications

Tailored strainer filter screens address unique operational challenges. For example:

- Agricultural Irrigation: Wide-diameter screens (6–12 inches) with anti-clogging designs.

- Marine Pumping Systems: Saltwater-resistant coatings and reinforced seams.

- Mining Operations: Heavy-duty mesh capable of filtering abrasive particles.

Customization options include variable mesh densities, modular attachments, and integration with IoT-based monitoring systems.

Case Studies: Real-World Efficiency Improvements

A municipal water treatment plant replaced legacy filters with self-cleaning pump suction screens, achieving:

- 65% reduction in pump clogging incidents.

- Annual maintenance cost savings of $18,000.

- 15% increase in daily water processing capacity.

Key Considerations for Maintenance and Longevity

Regular inspection intervals (every 500 operating hours) and prompt replacement of worn mesh components are essential. Data shows that proper maintenance extends strainer lifespan by 3–5 years, depending on application intensity.

Future Trends in Suction Hose Filtration Technology

Innovations like AI-driven clogging prediction and biodegradable strainer filter screens for water pump suction hoses are reshaping the industry. Manufacturers are also exploring graphene-enhanced meshes, which promise 300% greater durability than traditional materials. These advancements will further solidify the role of filtration systems in sustainable fluid management.

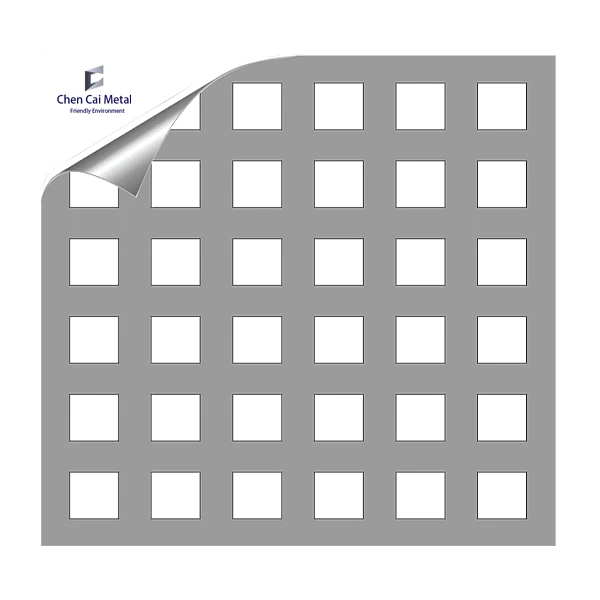

(strainer filter screen for water pump suction hose)

FAQS on strainer filter screen for water pump suction hose

Q: What is the purpose of a strainer filter screen for a water pump suction hose?

A: A strainer filter screen prevents debris, sediment, and particles from entering the water pump via the suction hose, ensuring smoother operation and protecting the pump from damage.

Q: How does a self-cleaning pump suction screen work?

A: A self-cleaning pump suction screen uses built-in mechanisms like backflushing or rotating brushes to automatically remove trapped debris, minimizing manual maintenance and maintaining consistent flow rates.

Q: What are the benefits of a mesh suction strainer for water pumps?

A: Mesh suction strainers offer fine filtration, durability, and corrosion resistance, making them ideal for applications requiring protection against small particles in water or chemical solutions.

Q: Where should a strainer filter screen be installed on a suction hose?

A: The strainer filter screen should be installed at the submerged end of the suction hose, ensuring it remains fully immersed to filter incoming water before it reaches the pump.

Q: Can a mesh suction strainer handle high-flow water pump systems?

A: Yes, high-quality mesh suction strainers are designed with robust materials and optimal surface area to handle high-flow systems while maintaining filtration efficiency without clogging.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)