In today's highly industrialized landscape, the integrity and purity of process fluids are paramount across virtually every sector, from petrochemical and power generation to food and beverage, and municipal water treatment. Contaminants, whether suspended solids, particulates, or unwanted debris, can lead to severe operational inefficiencies, costly equipment damage, reduced product quality, and even environmental hazards. This necessitates robust and reliable filtration solutions. Among the myriad of filtration technologies available, water filtration mesh stands out as a foundational component, offering unparalleled precision, durability, and versatility. Its role extends beyond simple particulate removal; it is integral to optimizing system performance, extending equipment lifespan, and ensuring compliance with stringent industry standards. The evolution of filtration mesh technology has been driven by increasing demands for finer filtration capabilities, enhanced material compatibility, and superior resistance to harsh operating environments. This includes developments in material science, manufacturing precision, and application-specific designs. For instance, the demand for sustainable practices has led to the development of reusable and easily cleanable mesh solutions, reducing waste and operational costs. The focus on high-performance materials like various grades of stainless steel, such as SS304 and SS316L, has become standard practice, particularly in applications where corrosion resistance and thermal stability are critical. Furthermore, innovations in mesh weaving and perforating techniques allow for unprecedented control over pore size and distribution, directly impacting filtration efficiency and flow characteristics. Understanding these foundational aspects is crucial for B2B decision-makers and technical personnel who are tasked with selecting, implementing, and maintaining filtration systems that meet both current operational needs and future strategic objectives. This comprehensive overview will delve into the technical nuances, manufacturing excellence, diverse applications, and strategic advantages of advanced filtration mesh, culminating in a detailed exposition of the T-Strainer Filtration Mesh, a prime example of cutting-edge filtration engineering.

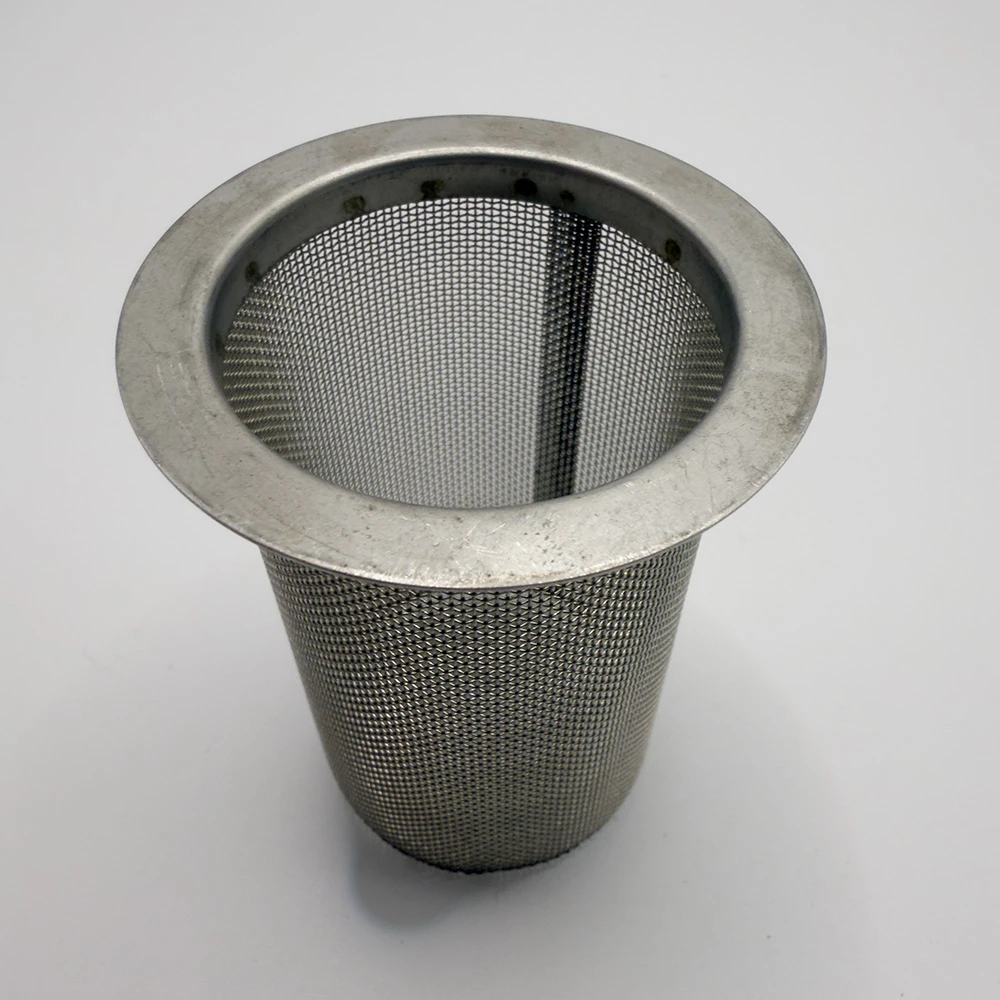

The demand for sophisticated filtration solutions is escalating due to several global trends. Rapid industrialization, particularly in developing economies, is increasing the volume and complexity of industrial effluents, necessitating more effective treatment before discharge. Simultaneously, growing populations and urbanization are placing immense pressure on limited fresh water resources, making advanced water purification technologies, heavily reliant on high-quality filtration mesh, indispensable. Moreover, advancements in manufacturing processes across various sectors, such as microelectronics and pharmaceuticals, require ultra-pure process fluids, driving the need for increasingly fine and precise filtration. The food and beverage industry, driven by consumer safety concerns and regulatory mandates, also demands sterile and contaminant-free production environments, where reliable filtration mesh is critical for product quality and shelf life. Environmental regulations are becoming stricter globally, mandating higher standards for effluent discharge and pollutant control, further boosting the adoption of superior filtration technologies. This comprehensive demand landscape underscores the strategic importance of choosing the right filtration components. Factors such as material compatibility with the fluid, temperature and pressure ratings, required filtration efficiency (often expressed in micron ratings), mechanical strength, and ease of maintenance are all critical considerations. Furthermore, the lifecycle cost, including initial investment, operational expenses, and potential for reduced downtime, plays a significant role in procurement decisions. As a result, manufacturers are continuously innovating, introducing products that offer improved performance, longevity, and cost-effectiveness. The T-Strainer Filtration Mesh exemplifies this innovation, designed to meet the rigorous demands of industrial applications requiring robust and efficient particle removal. Its design prioritizes operational stability and ease of servicing, key attributes for industrial environments where minimal downtime is crucial. This article will explore the specifics of such advanced filtration solutions, including their manufacturing intricacies, performance benchmarks, and diverse applications, providing a detailed understanding for technical buyers and engineers.

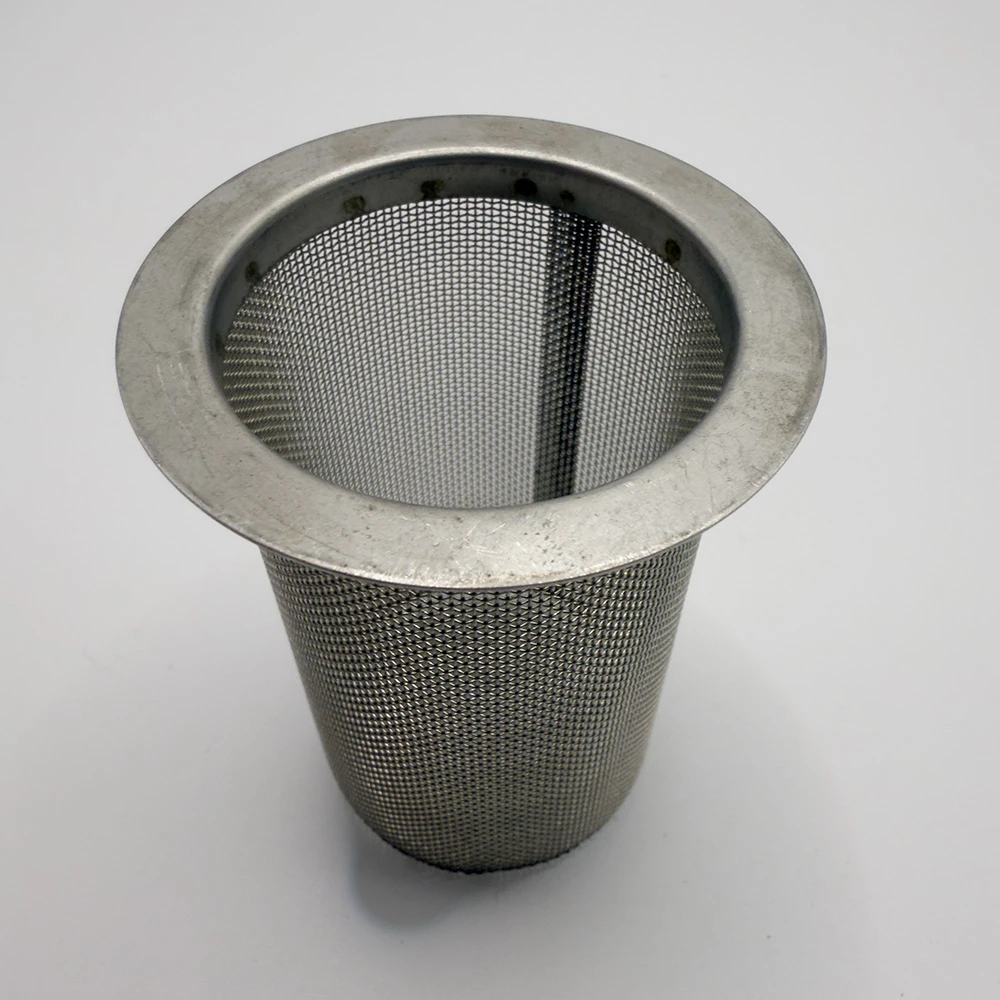

The production of high-quality water filtration mesh, particularly for precision components like the T-Strainer Filtration Mesh, is a sophisticated process that combines advanced material science with precision engineering. It begins with meticulous material selection, predominantly focusing on stainless steel grades such as SS304, SS316, and SS316L, chosen for their superior corrosion resistance, mechanical strength, and thermal stability. For highly aggressive environments or specific applications, exotic alloys like Hastelloy, Monel, or Titanium may be utilized, each selected for its unique properties, such as resistance to specific chemicals or extreme temperatures. The choice of material is critical as it directly impacts the mesh's durability, lifespan, and compatibility with the fluid being filtered. Once the material is selected, the manufacturing journey typically involves several key stages, ensuring the final product meets stringent performance specifications. The initial stage often involves wire drawing to achieve the precise wire diameter required for specific mesh sizes. This process is meticulously controlled to ensure uniformity and tensile strength. Following this, the wire is fed into sophisticated weaving looms, which meticulously interlace the wires to create a uniform mesh pattern. This weaving process, whether plain weave, twilled weave, or Dutch weave, dictates the mesh's pore size, open area, and mechanical strength. For perforated mesh, instead of weaving, sheets of metal are precision-punched with holes of specific sizes and patterns, offering higher rigidity and durability in certain applications. The precision of these processes is paramount; deviations in wire diameter or weaving tension can lead to inconsistent pore sizes, compromising filtration efficiency and potentially leading to bypass.

After the primary mesh material is produced, the fabrication of components like the T-Strainer Filtration Mesh involves further specialized processes. This often includes advanced cutting techniques, such as laser cutting or plasma cutting, to precisely shape the mesh and its supporting frame components. These methods ensure clean, burr-free edges, which are critical for preventing particle detachment and ensuring precise fit. Welding, a core manufacturing process for assembling the T-Strainer, is performed using techniques like Tungsten Inert Gas (TIG) welding or Laser Welding. These methods are chosen for their ability to create strong, clean, and crevice-free joints, which are essential for preventing leaks and inhibiting microbial growth in sanitary applications. The frames and baskets of the T-Strainer are often fabricated through bending, forming, or even CNC machining for complex geometries, ensuring structural integrity and precise dimensions for insertion into existing pipeline systems. Throughout the entire manufacturing process, rigorous quality control measures are implemented. This includes in-process inspections for dimensional accuracy, weld integrity, and visual defects. Post-fabrication, the finished filtration mesh components undergo a series of comprehensive tests. This typically includes hydrostatic pressure testing to verify structural integrity under operational pressures, flow rate testing to ensure the mesh meets specified throughput requirements with minimal pressure drop, and bubble point testing to confirm uniform pore size and detect any manufacturing flaws. Material analysis, such as X-ray fluorescence (XRF) or spectrographic analysis, is conducted to confirm the exact material composition and ensure it aligns with specified grades like SS316L, which is crucial for chemical compatibility and corrosion resistance. Compliance with international standards such as ISO 9001 for quality management, ASTM (American Society for Testing and Materials) for material specifications, and ANSI (American National Standards Institute) for design and performance criteria, is strictly adhered to, underscoring the product's reliability and superior quality. The meticulous attention to detail at every stage ensures that each T-Strainer Filtration Mesh delivers consistent, high-performance filtration, capable of withstanding the most demanding industrial environments and offering an extended service life.

Understanding the technical parameters of water filtration mesh is critical for selecting the appropriate solution for specific industrial applications. These parameters directly dictate the mesh's performance, efficiency, and suitability for various fluid dynamics and contaminant types. Key specifications include the micron rating, material composition, wire diameter, mesh count, open area percentage, and mechanical properties such as tensile strength and bursting pressure. The micron rating, perhaps the most fundamental parameter, defines the smallest particle size that the mesh can effectively capture. This can range from coarse filtration (hundreds of microns) for large debris removal down to ultra-fine filtration (as low as 1 micron) for highly sensitive applications like pharmaceutical production or microelectronics. Material composition, as previously noted, largely revolves around various grades of stainless steel filtration mesh, including SS304, SS316, and SS316L, with SS316L being particularly favored for its enhanced corrosion resistance, especially in environments with chlorides or acids. Wire diameter refers to the thickness of the individual wires used in the mesh, influencing both the strength and the open area. A thicker wire provides greater strength but reduces the open area, potentially impacting flow rate. Mesh count, defined as the number of openings per linear inch, directly correlates with the micron rating – a higher mesh count generally means finer filtration.

The open area percentage is a crucial parameter that represents the total area of the openings within the mesh as a percentage of the total mesh area. A higher open area allows for greater flow rates and lower pressure drop across the mesh, making it more energy-efficient and reducing pump load. However, increasing open area might also mean a coarser filtration. Achieving the optimal balance between micron rating, open area, and mechanical strength is a hallmark of expertly engineered filtration mesh. For T-Strainer Filtration Mesh, the structural integrity is paramount, considering it often operates under significant pressure differentials. Thus, mechanical properties like tensile strength (resistance to breaking under tension) and bursting pressure (the maximum pressure the mesh can withstand before rupture) are meticulously tested and specified. These parameters ensure the mesh maintains its structural integrity and filtration efficiency over extended periods, even under demanding operational conditions. Furthermore, temperature and chemical compatibility are vital considerations, ensuring the mesh material does not degrade or react with the process fluid or environmental conditions. Manufacturers often provide detailed chemical resistance charts for various stainless steel grades and other alloys. The surface finish, such as passivation or electropolishing, also plays a role in enhancing corrosion resistance and reducing surface roughness, which can prevent particle adhesion and facilitate easier cleaning. Below is a comprehensive table detailing typical technical parameters for high-performance water filtration mesh, including common ranges and their implications, providing a valuable resource for engineers in the selection process.

| Parameter | Typical Range/Value | Significance & Application |

|---|---|---|

| Micron Rating | 1 µm to 2000 µm (2 mm) | Defines the smallest particle effectively captured. Critical for product purity (e.g., 1-10 µm for pharmaceuticals) or equipment protection (e.g., 50-200 µm for pump protection). |

| Material Composition | SS304, SS316, SS316L (Standard); Duplex, Hastelloy, Monel, Titanium (Specialty) | Determines corrosion resistance, temperature tolerance, and chemical compatibility. SS316L is preferred for chlorinated or acidic environments. |

| Mesh Count (per inch) | 2 mesh to 635 mesh | Number of wires per linear inch. Higher count generally means smaller openings and finer filtration. Directly impacts micron rating. |

| Wire Diameter | 0.02mm to 1.6mm (approx.) | Thickness of individual wires. Influences mesh strength and open area. Thicker wires for robust applications. |

| Open Area Percentage | ~20% to 70% | Total percentage of open space. Higher open area means less pressure drop and higher flow rate, but potentially coarser filtration. |

| Temperature Range | -200°C to +800°C (depending on material) | Maximum and minimum operational temperatures the mesh can withstand without degradation. Stainless steel offers wide range. |

| Max Differential Pressure | Up to 500 PSI (34 bar) or more, basket dependent | The maximum pressure difference the mesh can sustain before deformation or failure. Critical for robust industrial processes. |

| Flow Rate | Application-specific, related to open area and pressure drop | Volume of fluid that can pass through the mesh per unit time. High open area facilitates higher flow rates with less energy. |

In addition to these core parameters, specialized considerations may include compliance with specific regulatory bodies, such as FDA for food and pharmaceutical applications, or API standards for oil and gas. For instance, the T-Strainer Filtration Mesh is designed to maximize flow while minimizing pressure drop, a critical feature for energy efficiency in large-scale fluid processing systems. Its robust construction ensures extended service life, even in highly abrasive or corrosive environments, significantly reducing maintenance frequency and associated costs. The precise control over mesh specifications ensures consistent filtration efficiency, safeguarding downstream equipment and maintaining product quality. Manufacturers often provide comprehensive data sheets for their mesh strainer basket products, detailing these parameters and offering guidance on selection based on specific operational requirements. This data-driven approach allows engineers to precisely match filtration solutions to their process needs, optimizing performance and ensuring long-term reliability.

The versatility of water filtration mesh makes it indispensable across a wide spectrum of industrial applications. Its primary function is to remove undesirable solid particles from liquids, protecting sensitive downstream equipment, ensuring product purity, and facilitating efficient process operations. In the Petrochemical Industry, filtration mesh is crucial for protecting pumps, heat exchangers, and sensitive instrumentation from catalyst fines, pipe scale, and other particulate matter found in crude oil, refined products, and various chemical streams. This directly prevents costly downtime, extends the lifespan of expensive machinery, and maintains product specifications. The Power Generation Sector, particularly thermal power plants and nuclear facilities, relies heavily on filtration mesh for cooling water intake, condensate polishing, and boiler feedwater treatment. Removing suspended solids prevents fouling of heat exchangers and turbine components, enhancing thermal efficiency and preventing catastrophic failures. In Municipal and Industrial Water Treatment, mesh is used in primary filtration stages for screening raw water sources, protecting disinfection systems, and in wastewater treatment for solid-liquid separation, reducing biological oxygen demand (BOD) and total suspended solids (TSS). The Food & Beverage Industry employs high-grade stainless steel filtration mesh for clarity filtration of beverages (juice, beer, wine), removal of unwanted solids in dairy processing, and ensuring sterile environments, often requiring FDA-compliant materials and sanitary designs. Similarly, the Pharmaceutical Industry demands ultra-fine filtration for drug formulation, active pharmaceutical ingredient (API) production, and sterile processing, where even microscopic particles can compromise product integrity and patient safety.

Beyond these core sectors, filtration mesh, including specialized designs like the T-Strainer Filtration Mesh, finds critical application in Mining and Mineral Processing for dewatering slurries and protecting pumps from abrasive solids. In Oil and Gas, it's used in upstream exploration for well completion fluids and downstream refining processes. The Pulp and Paper Industry uses mesh for white water recycling and stock preparation. Emerging applications include advanced manufacturing processes requiring ultra-pure cooling fluids and specialized chemical production where precise particle control is paramount. A significant advantage of employing high-quality water filtration mesh in these diverse scenarios is its contribution to energy savings. By efficiently removing particulates, it reduces fouling in heat exchangers and pipelines, maintaining optimal heat transfer coefficients and minimizing pressure drops, which directly translates to lower pumping energy consumption. Furthermore, its anti-corrosion properties, particularly with SS316L and other high-alloy meshes, significantly extend equipment lifespan in aggressive chemical environments, reducing replacement costs and maintenance interventions. The trend towards sustainable industrial practices is also driving innovation in filtration mesh. There's a growing emphasis on reusable, easily cleanable meshes that reduce the generation of disposable filter media waste. Automated backwashing and self-cleaning filter designs, often incorporating robust wire strainer basket components, are gaining traction, further enhancing operational efficiency and reducing manual labor. Moreover, the integration of smart sensors for real-time monitoring of differential pressure and fouling levels allows for predictive maintenance, optimizing filter cleaning cycles and preventing unexpected shutdowns. This proactive approach to filtration management represents a significant shift from reactive maintenance, leveraging data to maximize asset utilization and operational uptime. The T-Strainer Filtration Mesh is designed with these modern industrial demands in mind, offering superior performance, extended operational life, and ease of integration into existing or new process lines, making it a forward-looking choice for B2B applications.

Choosing the right water filtration mesh provider is a strategic decision for any industrial operation. Beyond just meeting technical specifications, a superior provider offers a comprehensive value proposition encompassing product quality, technical expertise, customization capabilities, and post-sales support. The strategic advantages of investing in high-quality filtration mesh are multifaceted. Firstly, Enhanced Equipment Protection: Precision filtration shields expensive pumps, valves, heat exchangers, and instrumentation from abrasive particles and debris, significantly extending their operational life and reducing capital expenditure on replacements. Secondly, Optimized Process Efficiency: By maintaining clean process fluids, the mesh prevents fouling, ensures consistent heat transfer, and minimizes pressure drops, leading to lower energy consumption and more stable process control. Thirdly, Superior Product Quality: In industries like food & beverage, pharmaceuticals, and specialty chemicals, precise filtration is non-negotiable for achieving desired product purity, clarity, and consistency, meeting stringent regulatory requirements and consumer expectations. Fourthly, Reduced Downtime and Maintenance Costs: Durable, high-performance mesh requires less frequent cleaning or replacement, translating to fewer production interruptions, lower labor costs, and improved overall equipment effectiveness (OEE). The T-Strainer Filtration Mesh, with its robust design and high-quality materials, embodies these advantages, engineered for longevity and minimal maintenance in demanding industrial environments.

When comparing vendors for stainless steel filtration mesh or a comprehensive mesh strainer basket solution, several critical factors should guide the decision-making process. Technical Expertise and Experience are paramount; a reputable vendor should possess deep knowledge of fluid dynamics, material science, and various industrial applications to provide accurate recommendations and troubleshooting support. Look for vendors with extensive experience in your specific industry. Manufacturing Capabilities and Quality Control are non-negotiable; assess their adherence to international standards like ISO 9001, their in-house testing facilities, and their ability to produce mesh with precise and consistent specifications. A vendor's commitment to quality ensures product reliability and performance. Customization and Engineering Support are crucial for unique or challenging applications. Many industrial processes require tailor-made filtration solutions, varying in material, micron rating, dimension, and configuration. A vendor capable of providing bespoke designs, from custom wire diameter and mesh count to specific basket geometries or exotic material fabrication, can offer significant operational advantages and cost savings by precisely meeting specific system requirements. This includes the ability to design a T-Strainer Filtration Mesh with specific flange connections, pressure ratings, or internal bypass mechanisms. After-Sales Support and Service including technical assistance, spare parts availability, and warranty policies, greatly influence the long-term value of the partnership. A strong support system minimizes operational risks and ensures timely resolution of any issues.

Our commitment to providing tailored filtration solutions for complex industrial challenges is a core strength. We understand that standard off-the-shelf products may not always meet the precise demands of every application. Therefore, we offer extensive customization options for our water filtration mesh products, including the T-Strainer Filtration Mesh. This includes, but is not limited to:

The true measure of a water filtration mesh solution lies in its real-world performance and documented success. Our experience across various industries demonstrates how precisely engineered T-Strainer Filtration Mesh and related products deliver tangible benefits.

Case Study 1: Mitigating Fouling in a Large-Scale Cooling Water System for a Chemical Plant

A major chemical manufacturing facility was experiencing persistent issues with biofouling and particulate accumulation in their cooling water system, leading to reduced heat exchanger efficiency, increased energy consumption, and frequent, unscheduled shutdowns for manual cleaning. Their existing filtration system, utilizing a coarser mesh, was ineffective at capturing the finer suspended solids and biological growth that contributed to the fouling. Our engineering team collaborated with the plant's technical staff to analyze their process fluid, flow rates, and existing system constraints. We recommended and supplied a custom-designed T-Strainer Filtration Mesh, fabricated from SS316L, with a precisely specified 50-micron rating and an optimized open area to maintain a low pressure drop. The SS316L material provided superior resistance to the slightly corrosive nature of their treated cooling water, which contained various chemical additives.

Outcome: Within three months of installation, the plant observed a significant reduction in differential pressure across their heat exchangers, indicating reduced fouling. Energy consumption for cooling water pumps decreased by an estimated 7-10% due to improved flow and reduced system resistance. Furthermore, the frequency of manual heat exchanger cleaning was cut by over 60%, resulting in substantial savings in labor costs and, more critically, an increase in operational uptime by an average of 48 hours per month. This directly translated into increased production output and improved profitability for the plant. The robust design of our wire strainer basket allowed for easy periodic cleaning without the need for specialized tools, contributing to its long-term operational success. This case exemplifies the expertise in providing solutions that address specific operational pain points, demonstrating the experience and authority required for complex industrial challenges.

Case Study 2: Enhancing Product Purity in a Pharmaceutical API Manufacturing Process

A leading pharmaceutical company faced challenges in maintaining the required purity levels for an Active Pharmaceutical Ingredient (API) due to trace particulate contamination in their solvent recovery loop. Their existing filtration system was unable to consistently achieve the sub-10 micron filtration required for their critical process. This led to batch rejections and significant reprocessing costs, impacting their production schedule and compliance. After a thorough assessment, we proposed a high-precision T-Strainer Filtration Mesh incorporating a Dutch weave stainless steel filtration mesh with a nominal 5-micron absolute rating. The entire assembly was electropolished to meet stringent sanitary and cleanability requirements for pharmaceutical applications, minimizing any potential for particle entrapment or microbial growth.

Outcome: The implementation of our specialized water filtration mesh resulted in a consistent and reliable capture of fine particulates, dramatically improving the purity of the recovered solvent. Batch rejections related to particulate contamination were virtually eliminated, leading to a 15% increase in overall API yield and a significant reduction in reprocessing costs. The robust construction and ease of cleaning of the T-Strainer also reduced maintenance time and ensured consistent performance, crucial for validated pharmaceutical processes. This case highlights our ability to deliver precise, compliant, and high-performance filtration solutions for the most demanding industries. Our authority is underpinned by adherence to rigorous manufacturing standards and certifications.

Quality Assurance and Certifications: The Foundation of Trust

Our unwavering commitment to quality is the cornerstone of our operations, building trustworthiness with our B2B partners. Every T-Strainer Filtration Mesh and associated filtration mesh product undergoes a multi-layered quality assurance process to ensure superior performance, reliability, and compliance with international standards. We are certified under ISO 9001:2015, demonstrating our adherence to a globally recognized quality management system that governs every aspect of our operations, from design and procurement to manufacturing, testing, and delivery. All raw materials, particularly stainless steel alloys, are sourced from reputable suppliers and subjected to rigorous incoming inspections, including Material Test Reports (MTRs) and independent chemical analysis (e.g., XRF testing) to verify exact composition and traceability to ASTM or EN standards.

During the manufacturing process, our skilled technicians employ Statistical Process Control (SPC) techniques to monitor and maintain tight tolerances for wire diameter, mesh count, and weave patterns. For fabricated components like the T-Strainer, critical dimensions are verified with precision instruments, and all welds undergo visual inspection, dye penetrant testing, and, where critical, X-ray inspection to ensure structural integrity and freedom from defects. Finished products undergo comprehensive performance testing. This includes hydrostatic pressure testing to ensure the entire assembly can withstand specified operating pressures without leakage or deformation, and flow rate validation to confirm that the mesh maintains optimal throughput with minimal pressure drop. For products destined for sanitary applications, specific surface roughness measurements and cleaning validation protocols are followed. Our consistent delivery of high-quality products is further supported by our extensive service history, spanning decades in the industrial filtration sector, and long-standing relationships with global industry leaders. This deep experience and consistent application of rigorous quality protocols provide our customers with unparalleled trust in our products and services.

At the core of any successful B2B partnership is trustworthiness, built upon transparency, clear communication, and reliable support. We believe in providing our clients with all the necessary information to make informed decisions and to ensure seamless operations with our water filtration mesh products, including the T-Strainer Filtration Mesh. Below are frequently asked questions (FAQs) and important details regarding our delivery, warranty, and customer support commitments.

Selecting the appropriate micron rating for your filtration mesh depends on several factors: the size and type of contaminants you need to remove, the desired purity level of your fluid, and the sensitivity of downstream equipment. We recommend conducting a particle size analysis of your fluid. Our technical sales engineers are available to assist you in this assessment and recommend the optimal mesh size based on your specific operational parameters and objectives. Providing us with details on fluid viscosity, flow rate, and acceptable pressure drop will also greatly aid in this selection process.

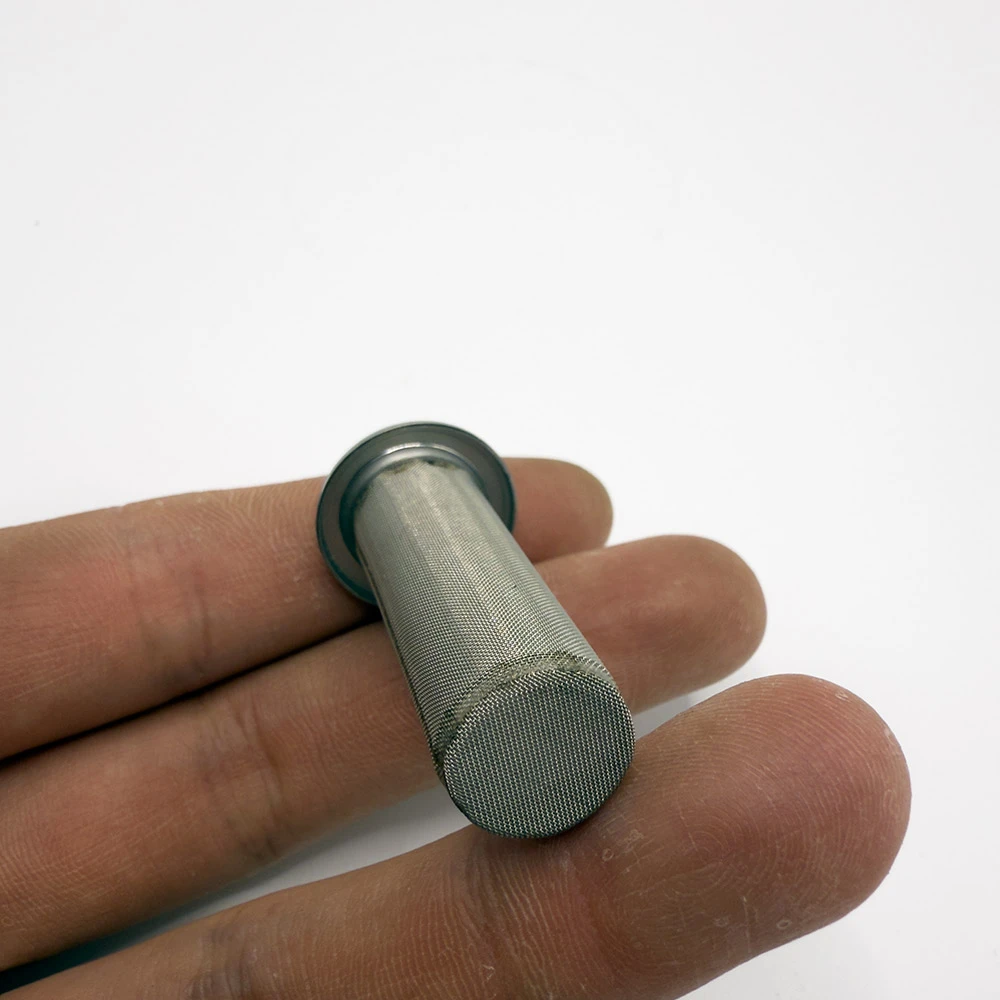

The lifespan of a T-Strainer Filtration Mesh is highly variable, depending on the fluid's cleanliness, operating pressure, temperature, and cleaning frequency. Under normal operating conditions and with proper maintenance, our stainless steel filtration mesh products can last for many years. Maintenance typically involves periodic removal and cleaning of the mesh basket. Cleaning methods include backflushing, manual scrubbing with appropriate detergents, or ultrasonic cleaning for very fine meshes. We provide detailed cleaning instructions and can advise on optimal cleaning cycles based on your specific application to maximize the lifespan of your mesh strainer basket.

Absolutely. We offer a range of materials specifically designed for extreme conditions. While SS316L is excellent for many corrosive environments, for highly aggressive chemicals or very high temperatures, we provide water filtration mesh made from specialized alloys such as Hastelloy, Monel, Inconel, Duplex stainless steel, and Titanium. Our engineering team will work with you to select the most suitable material based on your fluid's chemical composition and your process's temperature profile to ensure optimal performance and longevity.

Lead times for custom orders of T-Strainer Filtration Mesh vary depending on the complexity of the design, material availability, and current production schedule. For standard configurations with readily available materials, lead times can range from 3-6 weeks. For highly complex or specialized material orders, lead times may be longer. We provide an estimated delivery schedule upon quotation and keep you informed throughout the manufacturing process. Our efficient production planning aims to minimize lead times without compromising quality.

Yes, comprehensive technical support is an integral part of our commitment to customer satisfaction. Our experienced engineers are available to provide guidance on proper installation procedures, system integration, and troubleshooting any operational issues that may arise. We offer remote support via phone and video conferencing, and for critical applications, on-site technical assistance can be arranged. Our goal is to ensure your wire strainer basket operates effectively and efficiently throughout its service life.

We understand the importance of timely delivery for maintaining your operational schedules. Our logistics team works diligently to ensure that your water filtration mesh orders are processed efficiently and shipped through reliable carriers. We provide detailed tracking information for all shipments and communicate proactively regarding any potential delays. For urgent requirements, expedited shipping options can often be arranged. Our packaging is designed to protect the integrity of the delicate mesh products during transit, ensuring they arrive in perfect condition, ready for installation. We also manage international shipments, adhering to all relevant customs and export regulations, simplifying the procurement process for our global clientele.

Every T-Strainer Filtration Mesh and all our filtration mesh products are backed by a comprehensive quality warranty, typically covering manufacturing defects and material integrity for a specified period from the date of purchase. The exact terms of the warranty are detailed in our product documentation and can be discussed with our sales team. Our commitment to quality extends beyond the sale; our dedicated customer support team is readily available to address any inquiries, provide technical assistance, or resolve any issues you may encounter. We believe that robust after-sales support is crucial for long-term customer satisfaction and operational reliability. Your success is our priority, and we strive to build lasting partnerships through unparalleled product quality and responsive service.

The landscape of industrial fluid processing is continuously evolving, driven by an increasing emphasis on efficiency, sustainability, and stringent quality control. In this dynamic environment, the role of high-performance water filtration mesh, particularly specialized solutions like the T-Strainer Filtration Mesh, becomes ever more critical. As industries navigate challenges such as rising energy costs, tighter environmental regulations, and the demand for higher product purity, investing in superior filtration technologies is no longer an option but a strategic imperative. The detailed exposition of the manufacturing processes, technical parameters, diverse application scenarios, and the demonstrable advantages of our T-Strainer Filtration Mesh underscores its position as a leading solution for complex industrial filtration needs. From the meticulous selection of high-grade stainless steel (like SS316L) to precision weaving, fabrication, and rigorous quality assurance testing, every step in our production process is geared towards delivering a product that offers unmatched durability, consistent performance, and exceptional value. Our commitment to innovation is reflected in our continuous research and development efforts, exploring new materials, improved mesh geometries, and advanced manufacturing techniques to meet the future demands of industrial filtration. This includes advancements in creating meshes that are even more resistant to fouling, easier to clean in-situ, and capable of operating under increasingly extreme conditions of pressure and temperature. The integration of smart technologies, enabling real-time monitoring and predictive maintenance, is also a key area of focus, moving towards a more data-driven approach to filtration management.

Beyond product excellence, our commitment extends to being a trusted partner for B2B decision-makers and technical personnel. We pride ourselves on our deep technical expertise, demonstrated through our ability to offer comprehensive engineering support, customized solutions, and responsive after-sales service. We understand that each industrial application presents unique challenges, and our collaborative approach ensures that the chosen filtration mesh solution is perfectly aligned with your specific operational requirements and strategic objectives. Whether it's enhancing equipment protection in a petrochemical plant, ensuring product sterility in a pharmaceutical facility, or optimizing energy consumption in a power generation unit, our stainless steel filtration mesh products are engineered to deliver measurable improvements. The global trend towards water scarcity and the increasing need for water recycling and reuse also places a greater emphasis on efficient and reliable water filtration mesh technologies. Our solutions contribute directly to these sustainability goals by enabling cleaner water discharge and facilitating closed-loop process water systems. Choosing a supplier with a proven track record, adherence to international quality standards, and a customer-centric approach is paramount for long-term success. We invite you to explore how our T-Strainer Filtration Mesh and extensive range of wire strainer basket products can elevate your operational efficiency, reduce costs, and ensure the highest standards of fluid purity in your industrial processes. Our expertise is your advantage in navigating the complexities of industrial filtration.

PREV:

This is the last article