|

Nkan

|

Apejuwe

|

|

Orukọ ọja

|

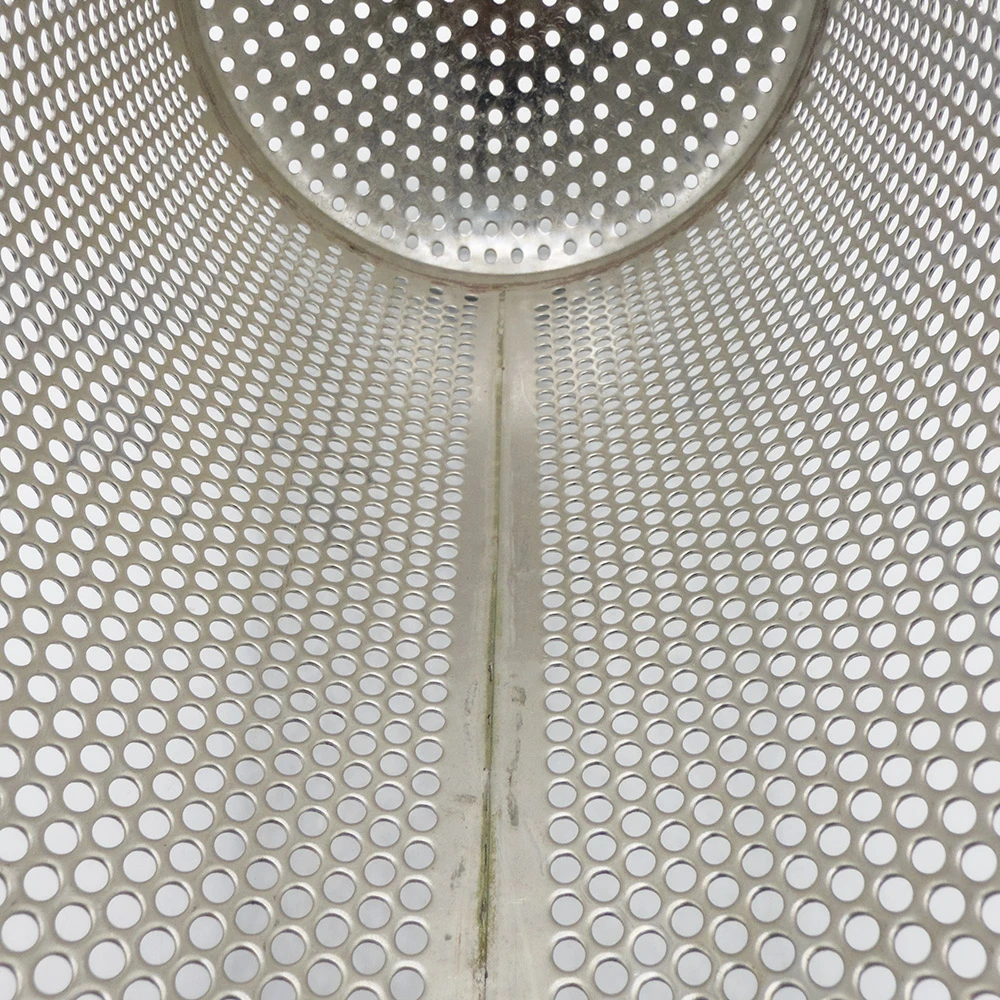

Irin Alagbara Irin Perforated Ajọ (Asẹ Apo/Eto Ajọ)

|

|

Ohun elo

|

Irin Alagbara 304/316L (sooro ibajẹ, o dara fun ounjẹ ati awọn ile-iṣẹ kemikali)

|

|

Ilana

|

Silindrical perforated irin apapo, pẹlu iyan akojọpọ support Layer ati flange asopọ

|

|

Yiye sisẹ

|

Iwọn iho: 0.5mm - 20mm (Aṣaṣe)

|

|

Awọn iwọn

|

Aṣeṣeṣe (awọn iwọn wọpọ: Opin 100-1000mm, Giga 100-11000mm)

|

|

Sisanra

|

0.3mm - 10mm (Aṣeṣe)

|

|

Iho Iru

|

Awọn ihò iyipo, awọn iho onigun mẹrin, awọn iho abọ (Ṣiṣe deede si awọn abuda omi oriṣiriṣi)

|

|

Apeere ti Ipese sisẹ (μm)

|

|

Iwon iho (mm)

|

Ipese sisẹ (μm)

|

Application

|

|

5.0

|

5000

|

ti o tobi patiku yiyọ

|

|

2.0

|

2000

|

o dara fun yiyọ idoti nla

|

|

1.0

|

1000

|

yiyọ ti o tobi ri to impurities

|

|

0.5

|

500

|

yiya omi patikulu

|

|

0.1

|

100

|

Ultra-itanran ase

|

|

Fun Sisẹ konge ti o ga julọ (1-50μm), ohun afikun apo àlẹmọ itanran tabi awọ inu le ti wa ni ese pẹlu awọn alagbara, irin perforated apapo lati se aseyori superior išẹ.

Ṣe o fẹ iṣeduro fun awọn ti aipe Iho iwọn ati ki o ohun elo da lori rẹ elo? Jẹ ki mi mọ ibeere rẹ Òdíwọ̀n ìsẹ̀lẹ̀ (μm)!

|

|

|

Ṣii Iwọn Agbegbe

|

20% - 60% (Iṣapeye fun ṣiṣe sisan)

|

|

Asopọmọra Iru

|

Flange, dimole, tabi asapo asopọ (Ni ibamu pẹlu ọpọlọpọ awọn eto isọ)

|

|

Awọn iwọn otutu ti nṣiṣẹ

|

-50°C si 500°C (O dara fun awọn agbegbe iwọn otutu giga)

|

|

Titẹ Resistance

|

Titi di 30 MPa (Da lori ohun elo ati sisanra)

|

|

dada Itoju

|

1. Pickling (irin alagbara (304, 316L), irin carbon, nickel-based alloy (Monel, Hastelloy)

2. Electrolytic Polishing (irin alagbara (304, 316L), nickel-based alloy (Monel, Hastelloy))

Ati bẹbẹ lọ

|

|

Ipata Resistance

|

Acid ati Alkaki Resistant, Giga-Ooru Resistant, Oxidation Resistant

|

|

Media to wulo

|

Omi, epo, afẹfẹ, awọn solusan kemikali, awọn olomi ounje, ati bẹbẹ lọ.

|

|

Ohun elo Industries

|

Ṣiṣe ounjẹ ounjẹ, sisẹ kemikali, awọn oogun, itọju omi idọti, isọdọtun epo, sisẹ irin, ati bẹbẹ lọ.

|

|

Awọn ẹya ara ẹrọ

|

1. Agbara giga – Perforated alagbara, irin mesh be, ipa-sooro, o dara fun ga-titẹ agbegbe

2. Ibajẹ-ibajẹ - Ti a ṣe ti 304 / 316L irin alagbara, ti o dara fun awọn agbegbe acidic ati ipilẹ.

3. Reusable & Washable - Gigun iṣẹ igbesi aye, idinku awọn idiyele sisẹ

4. Išẹ ṣiṣan ti o dara julọ - Iwọn agbegbe ti o ga julọ, ti o dinku idena omi ati imudara imudara sisẹ

5. Fifi sori ẹrọ ti o rọrun - Flange ti o ni idiwọn tabi awọn asopọ ti o tẹle, ti o ni ibamu pẹlu awọn ọna ṣiṣe pupọ

|

|

Awọn aṣayan isọdi

|

Awọn iwọn, awọn iwọn iho, awọn ohun elo, sisanra, ati awọn iru asopọ le jẹ adani

|

|

Iṣakojọpọ

|

Ṣiṣu apo + paali + Onigi crate (Ẹri-ọrinrin ati ẹri ipata fun gbigbe ilu okeere)

|

![$nkan[akọle] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)