|

Ihe

|

Nkọwa

|

|

Aha ngwaahịa

|

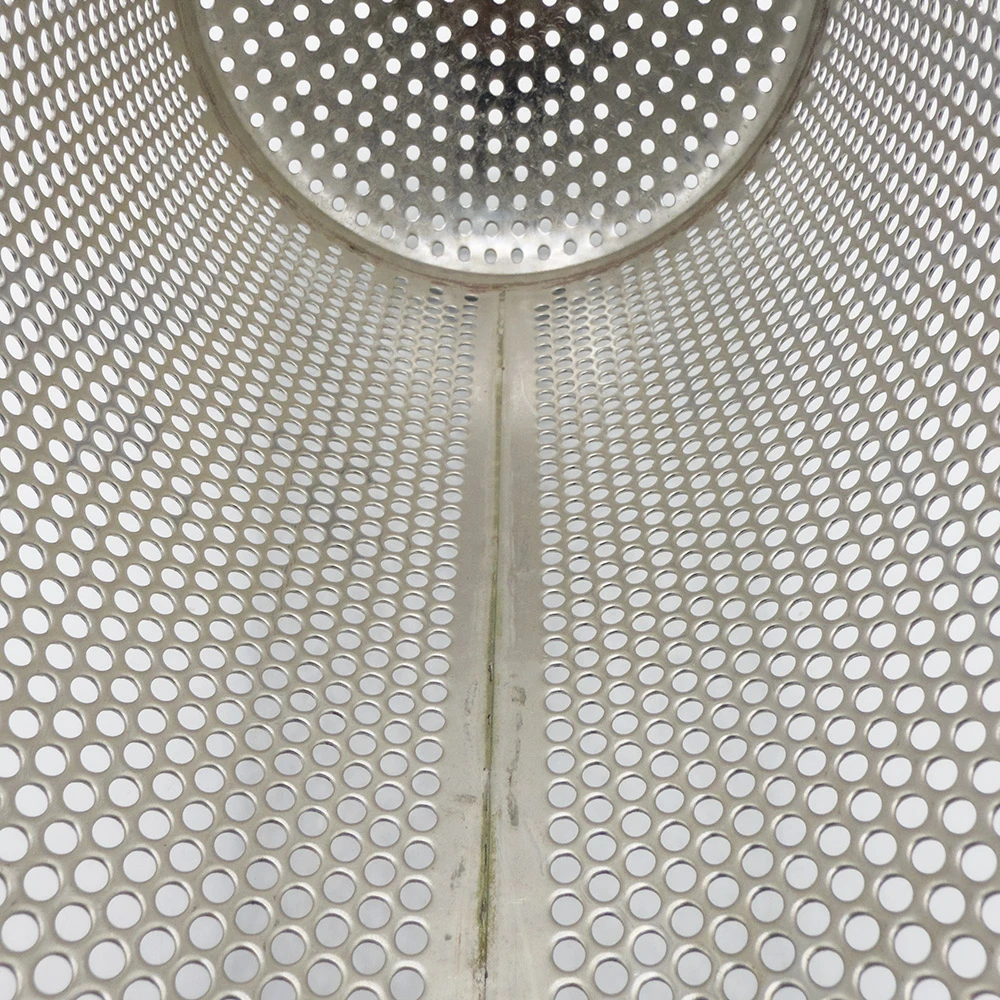

Ihe nzacha igwe anaghị agba nchara (Nzacha akpa/Sistemụ nzacha)

|

|

Ihe onwunwe

|

Igwe anaghị agba nchara 304/316L (ihe na-eguzogide corrosion, dabara maka ụlọ ọrụ nri na kemịkalụ)

|

|

Nhazi

|

Ntupu ígwè nwere cylindrical perforated, na nhọrọ nkwado oyi akwa na njikọ flange

|

|

Ịdị mma nzacha

|

Ogo oghere: 0.5mm - 20mm (Enwere ike ịhazi ya)

|

|

Akụkụ

|

Enwere ike ịhazi ya (Nha nkịtị: Dayameta 100-1000mm, ịdị elu 100-11000mm)

|

|

Ọkpụrụkpụ

|

0.3mm - 10mm (nwere ike ịhazi ya)

|

|

Ụdị oghere

|

Oghere okirikiri, oghere hexagon, oghere ndị nwere ogologo (Nkwekọrịta na njirimara mmiri dị iche iche)

|

|

Ọmụmaatụ nke Nzacha nzacha (μm)

|

|

Nha oghere (mm)

|

Nzacha nzacha (μm)

|

Application

|

|

5.0

|

5000

|

nnukwu mkpochapụ

|

|

2.0

|

2000

|

adabara nnukwu mkpochapụ

|

|

1.0

|

1000

|

wepụ ibu siri ike adịghị

|

|

0.5

|

500

|

na-ewere akụkụ mmiri mmiri

|

|

0.1

|

100

|

Ultra-mma filtration

|

|

Maka nzacha nkenke dị elu (1-50μm), ihe ọzọ mma nzacha akpa ma ọ bụ n'ime lining enwere ike jikọta ya na igwe anaghị agba nchara perforated ntupu iji nweta arụmọrụ dị elu.

Ọ ga-amasị gị nkwanye maka ezigbo oghere nha na ihe onwunwe dabere na ngwa gị? Mee ka m mara ihe ịchọrọ ọkọlọtọ filtration (μm)!

|

|

|

Mepee Oke Mpaghara

|

20% - 60% (Ekepụtara maka ịrụ ọrụ nke ọma)

|

|

Ụdị njikọ

|

Njikọ flange, mkpọgide ma ọ bụ eri (dakọtara na usoro filtration dị iche iche)

|

|

Okpomọkụ na-arụ ọrụ

|

-50°C ruo 500°C ( Kwesịrị ekwesị maka gburugburu okpomọkụ dị elu)

|

|

Nguzogide nrụgide

|

Ruo 30 MPa (dabere na ihe na ọkpụrụkpụ)

|

|

Ọgwụgwọ elu

|

1. Pickling (igwe anaghị agba nchara (304, 316L), carbon ígwè, nickel dabeere alloy (Monel, Hastelloy)

2. Electrolytic Polishing (igwe anaghị agba nchara (304, 316L), nickel dabeere alloy (Monel, Hastelloy))

wdg

|

|

Nguzogide corrosion

|

Acid na Alkali na-eguzogide, Igwe ọkụ dị elu, Nguzogide Oxidation

|

|

Mgbasa ozi dị

|

Mmiri, mmanụ, ikuku, kemịkalụ ngwọta, nri mmiri mmiri, wdg.

|

|

Ụlọ ọrụ ngwa

|

Nhazi nri, kemịkalụ filtration, ọgwụ ọgwụ, ọgwụgwọ mmiri mkpofu, ncha mmanụ, nhazi ígwè, wdg.

|

|

Atụmatụ

|

1. Akwa ike - Perforated igwe anaghị agba nchara ntupu Ọdịdị, mmetụta na-eguzogide, adabara elu-nrụgide gburugburu.

2. Corrosion-eguzogide - Mere nke 304/316L igwe anaghị agba nchara, adabara acidic na alkaline gburugburu

3. Reusable & Washable - Ogologo ndụ ọrụ, na-ebelata ụgwọ nzacha

4. Ọmarịcha arụmọrụ na-asọ asọ - Mpaghara oghere dị elu, na-ebelata nkwụsị nke mmiri na imeziwanye arụmọrụ nzacha

5. Nrụnye dị mfe - Flange ọkọlọtọ ma ọ bụ njikọ eriri, dakọtara na usoro dị iche iche

|

|

Nhọrọ nhazi

|

Enwere ike ịhazi nha, nha oghere, ihe, ọkpụrụkpụ na ụdị njikọ

|

|

Nkwakọ ngwaahịa

|

Akpa rọba + Katọn + Osisi osisi (ihe na-egbochi mmiri na ihe nchara maka mbupu mba ofesi)

|

![$ihe[aha] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)