Industry Trends in Perforated Metal Technology

Architectural and industrial applications of round perforated metal have grown exponentially over the past decade. Market research from IBISWorld indicates a 6.4% annual growth in perforated metal products demand from 2021-2026, primarily driven by construction and industrial filtration sectors.

The emergence of advanced manufacturing techniques has enabled manufacturers like Anping Chen Cai Metal to achieve hole tolerances of ±0.01mm in our round perforated metal products. Such precision has expanded potential applications to include:

- Acoustic paneling in modern architectural designs

- High-efficiency filtration systems for chemical processing

- Precision sieving in pharmaceutical manufacturing

- Decorative elements in automotive and aerospace design

- Safety guarding for industrial machinery

"Perforated metals have evolved from basic functional materials to high-performance engineered solutions. Modern manufacturing capabilities allow for unprecedented control over hole patterns and material properties."

-

Society of Manufacturing Engineers

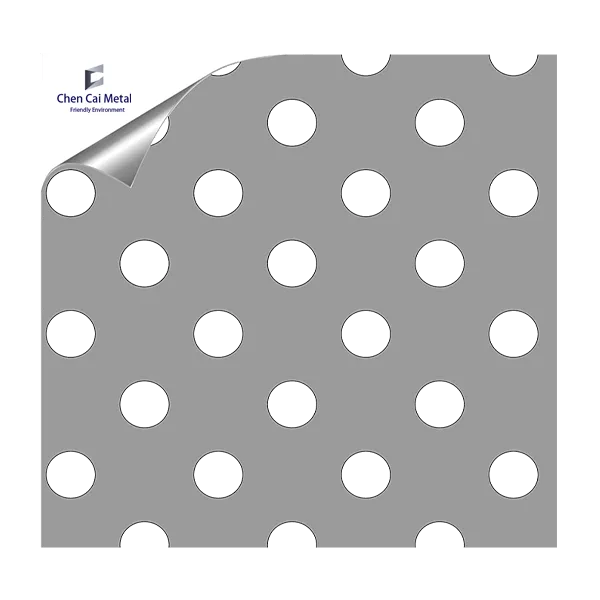

Flagship Product: Round Staggered 45° Perforated Sheet

Our premium product line features the Round Staggered 45° Perforated Sheet, engineered for applications requiring superior structural integrity and precise hole patterns.

Product Specifications:

| Material |

Thickness Range |

Hole Dia (mm) |

Center Distance (mm) |

Open Area (%) |

| Stainless Steel 304/316 |

0.5-6.0mm |

0.8 |

2.5 |

16.1 |

| Carbon Steel |

1.0-8.0mm |

2.0 |

6.0 |

17.4 |

| Aluminum |

0.8-4.0mm |

2.0 |

7.5 |

11.2 |

View Product Details

Material Advantages

Our round hole perforated stainless steel sheet options provide exceptional corrosion resistance, making them ideal for:

- Marine and coastal architectural applications

- Chemical processing equipment

- Food and beverage manufacturing facilities

- Medical sterilization equipment

For architectural applications, our aluminum round perforated metal sheets provide strength-to-weight ratios exceeding 40 MPa/(kg/m³), outperforming alternative materials in weight-sensitive installations.

Applications Across Industries

Architectural Design

Our round perforated metal sheet products have transformed modern architecture with applications including:

- Solar shading systems reducing cooling loads by up to 28%

- Acoustic panels with noise reduction coefficients up to 0.95

- Decorative facades providing dynamic daylight modulation

- Safety balustrades meeting OSHA requirements

"Perforated metal facades offer architects unprecedented control over light, ventilation, and visual permeability. The 45° staggered hole pattern creates unique optical effects at different viewing angles."

-

ArchDaily Technical Journal

Industrial Applications

In industrial settings, precision metal sheet perforated round hole components serve critical functions:

- Filter screens removing particulates to 5μm efficiency

- Centrifuge baskets with uniform flow distribution

- Safety guards meeting ISO 13857 standards

- Vibration damping platforms reducing harmonic resonance

Case Study: Automotive manufacturing plant implemented our stainless steel round perforated metal safety guards that reduced maintenance costs by 42% while increasing air flow by 27% compared to previous wire mesh solutions.

Manufacturing Excellence

At Anping Chen Cai Metal, we employ CNC-controlled punching equipment with positioning accuracy of ±0.02mm. Our production process features:

- Automated optical inspection for hole pattern verification

- Statistical process control maintaining Cpk values >1.67

- Laser cutting of perimeter profiles with ±0.1mm tolerance

- Electropolishing for medical-grade surface finishes

- Dimensional verification against ASME Y14.5 standards

Quality control testing includes salt spray testing per ASTM B117 (>1000 hours for stainless), material composition verification via XRF spectroscopy, and hole tolerance verification using optical comparators.

Technical FAQ: Round Perforated Metal Solutions

Q1: What tolerance standards do your round perforated metal products meet?

A: Our precision round perforated metal sheets comply with ASTM E2016-15 dimensional tolerance standards. Hole diameter tolerance is maintained at ±0.025mm for holes under 3mm and ±0.05mm for larger diameters. Positional tolerance is held to ±0.05mm across full sheet dimensions.

Q2: How does the 45° staggered pattern differ from straight patterns?

A: The 45° staggered configuration (vs straight alignment) provides increased structural integrity with a 22-35% higher load-bearing capacity. This orientation also creates optimal material distribution during punching, allowing thickness-to-diameter ratios up to 1:1.2, compared to 1:1.5 for straight patterns.

Q3: What installation standards apply to architectural perforated metal facades?

A: Installation must comply with ASTM E283 (air infiltration), ASTM E331 (water penetration), and local wind load requirements. Our engineering team provides support calculations meeting IBC 2018 Chapter 24 and ASCE/SEI 7-16 standards for projects.

Q4: What surface treatments are recommended for outdoor applications?

A: For coastal environments, we recommend 316 stainless steel with electropolished finish. In non-coastal settings, carbon steel with powder coating per AAMA 2605 provides excellent protection. Aluminum sheets should undergo chromate conversion coating per MIL-C-5541 Class 3.

Q5: Can you manufacture customized hole patterns?

A: Our CNC punching equipment can produce specialized patterns with hole diameters ranging from 0.5mm to 50mm and center distances from 1.0mm. Custom patterns typically require a minimum order quantity of 10 square meters for development.

Q6: How do I calculate open area for custom specifications?

A: For staggered round holes, use the formula: Open Area % = [(π × d²) / (2 × S² × sin(60°))] × 100, where d = hole diameter, S = center distance. Our engineering team provides calculations for all projects.

Q7: What quality certifications does your manufacturing facility hold?

A: Our facility maintains ISO 9001:2015 certification, with material traceability per EN 10204 3.1. We undergo annual audits for dimensional tolerances to ASME Y14.5 and material verification to ASTM A480.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)